Challenge

Jet engines and rocket motors produce very hot exhaust gases whose expansion creates mechanical power. Although many components of the engines are internally cooled, there are always surfaces that directly contact the hot gas. Many engine designs include ceramic coatings to protect these surfaces.

The drive toward greater engine efficiency and lighter weight means that newer engines use advanced materials and operate at higher temperatures than ever before. This creates a need to understand and improve the reliability of high-temperature ceramic coatings.

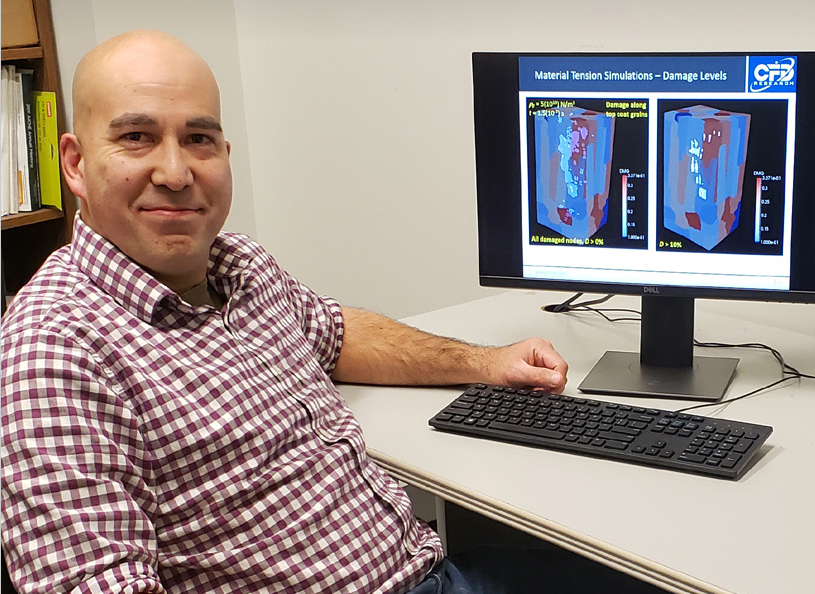

“The collaboration with Sandia has been very valuable in the analysis of damage processes in advanced coating systems. The peridynamics modeling approach, and the Emu software, provide unique capabilities for characterizing material response mechanisms under adverse operating conditions.”

David Newsome

Principal Engineer

CFD Research

Collaboration

Under the sponsorship of the Air Force, Navy, and NASA, Sandia National Laboratories is partnering with CFD Research to develop a computational tool for analyzing the microscopic processes that affect the performance of these coatings. The team is applying Sandia’s Emu peridynamic software code to the problem.

Peridynamics is a mathematical theory of mechanics used to model fractures in metals and components that was developed by Sandia scientist Stewart Silling. Emu is a computer code that implements the peridynamic model.

CFD Research, a company that specializes in engineering and innovative designs for aerospace, defense, and other industries, is licensing Emu, modifying it for the particular needs of this class of problems, and coupling it with their other fluid mechanics code. Silling worked together with CFD Research scientists to integrate the two codes to create the new software tool.

Solution

CFD Research has improved the capabilities of the Emu code to model the complex processes at work as high temperature gas flows past the coating. These processes include heat conduction, mechanical pressure and drag, cracking, debonding of the coating, the impact of dust and debris, and the transport of chemical contaminants within the materials.

Engineers typically use finite element method (FEM)-based codes to analyze the mechanical response of aerospace structures. However, ceramic coatings, due to their complex structure and material properties, require a microscale approach to analyze their response to external stimuli. The Emu code from Sandia provides a number of mathematical models and material properties for this specialized application.

Impact

The new modeling capability that combines Emu with state-of-the-art fluid dynamics codes is being developed and delivered to the relevant U.S. government agencies. These innovative modeling tools will be applied to analyze the reliability and safety of new material coatings for engine components. Sandia’s research also helps in the analysis of high velocity flight vehicles as part of its nuclear weapons mission.