R&D World magazine honors inventors by identifying the 100 most technologically significant products and advancements each year and recognizing the winning innovators and their organizations. Winners are chosen from an international pool of submissions from universities, private corporations, and government labs.

In 2025, Sandia researchers took home eight R&D 100 Awards. Since 1963, Sandia has earned 165 awards, including this year’s winners — often referred to as the “Oscars of invention” or “the Nobel Prizes of technology.”

2025 winners

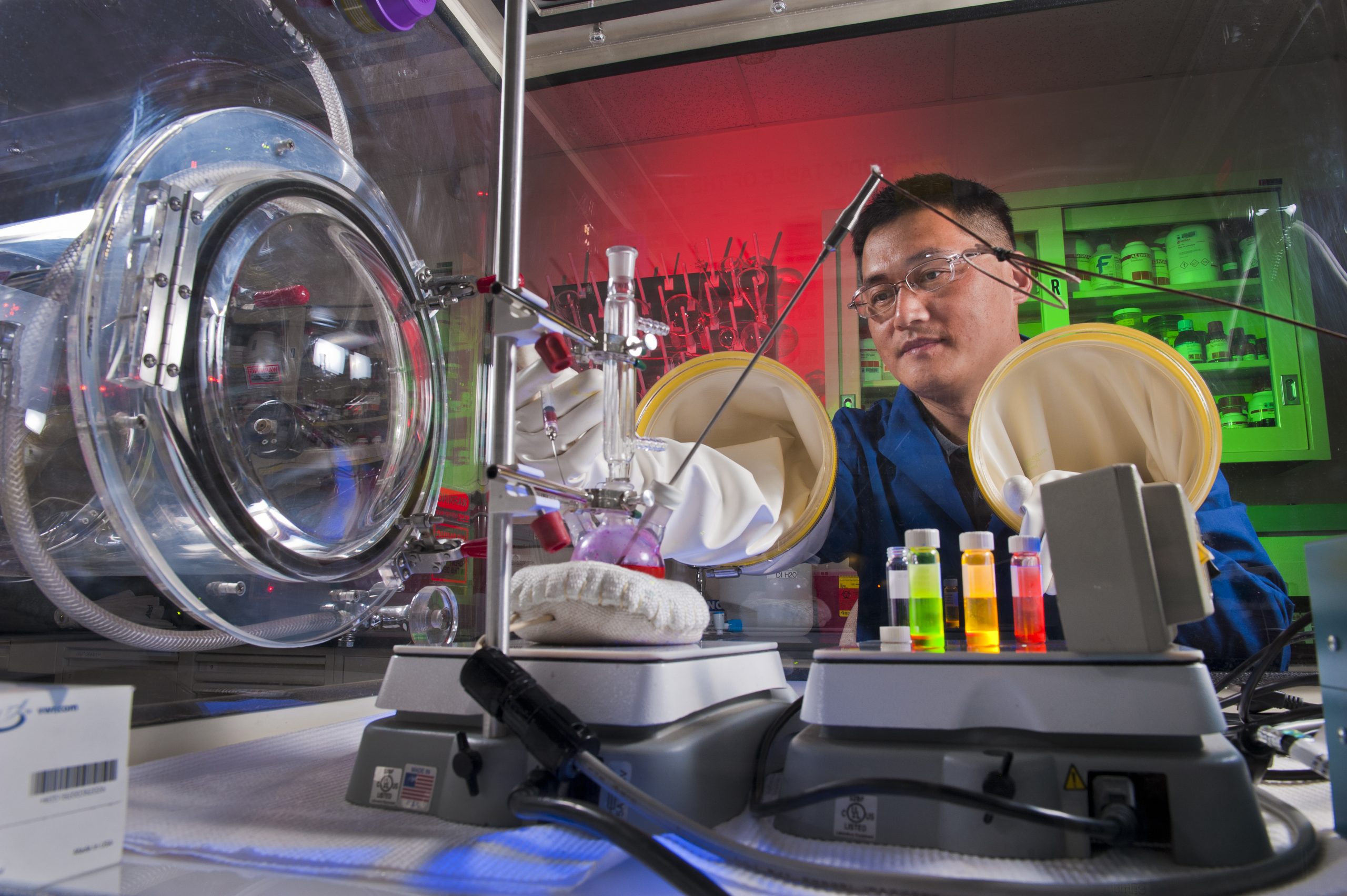

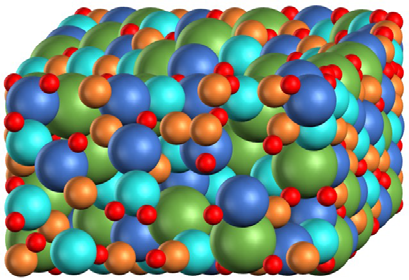

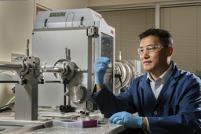

Researcher of the Year: Hongyou Fan

Sandia researcher Hongyou Fan, who has been called a “serial innovator” by his peers, is an internationally recognized leader in chemical science, materials science, and nanoscience and nanotechnology, whose pioneering research has significantly advanced DOE missions in science, energy, and national security. His transformative research work, some of which was founded in LDRD projects at Sandia, has driven groundbreaking innovations, resulting in 24 patents and the founding of two companies, Lunano, LLC, and Critical Materials, LLC.

Having won six R&D 100 Awards and six Federal Laboratory Consortium (FLC) Awards in Technology Transfer, Fan’s achievements have also been widely recognized by leading professional societies, and both state and national legislators. These honors underscore his pivotal role in advancing the nation’s innovation ecosystem and exemplify his unwavering commitment to leveraging science and engineering not only for societal benefit but to inspire the next generation of engineers and scientists.

Electro-Optical Sensor (EOS) for High-Energy Environments and Applications

IT/Electrical – Winner

The Electro-Optical Sensor (EOS) offers a new solution to a long-standing challenge in measuring high voltages. It uses a tiny crystal, about the size of a dime, and a laser smaller than a shoebox to measure voltages up to 20 million volts without touching the electrical source. This non-contact method makes it safer to operate in situations where traditional methods may pose risks.

The EOS provides a clear and direct relationship between the measurement it takes and the actual voltage, which makes the process easier and more reliable. Additionally, its potential uses extend beyond just high-energy physics; it can also be applied in areas like lightning research and monitoring electrical utilities, showcasing its versatility and wide-ranging impact.

The remarkable EOS does have connections to Laboratory Directed Research & Development (LDRD) projects.

Colorized Hyperspectral X-Ray Imaging with Multi-Metal Targets (CHXI–MMT)

Analytical/Test – Winner

The CHXI-MMT technology is a major breakthrough in X-ray imaging, especially since there have been minimal advancements in the way x-ray images are acquired for over the past 50 years. By combining a special nano-patterned X-ray source with advanced detection methods, this technology provides incredibly detailed images that enhance diagnostic accuracy and analysis depth. In addition to imaging, it also identifies materials by examining how they absorb different wavelengths of x-rays. This dual capability of high-resolution imaging and precise material characterization marks a significant advancement, particularly valuable in medicine, materials science, and forensics.

Because it enables high-precision measurements with traditional X-ray sources, it reduces the need for costly accelerator facilities and makes advanced imaging techniques more accessible to various industries and research institutions.

The technology addresses traditional X-ray imaging’s limitations while enhancing reliability and accuracy, which is crucial for applications like surgical planning and structural integrity assessments. Overall, its capabilities open new possibilities in biomedical imaging, TSA applications, non-destructive testing, and advanced manufacturing, driving innovation and breakthroughs in science and technology.

This breakthrough has roots in four LDRD projects beginning with one in 2012.

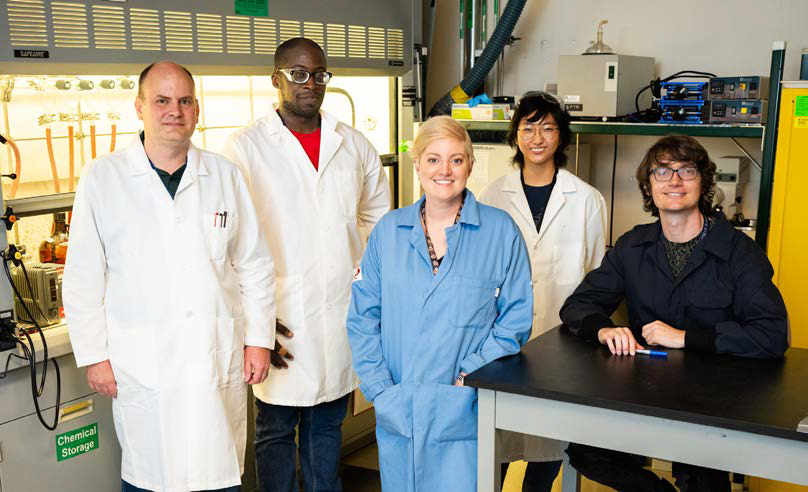

Fentanyl Analog Independent Detector (FAID)

Analytical/Test – Winner

The Fentanyl Analog Independent Detector (FAID) is a groundbreaking, hand-portable technology that revolutionizes public safety by delivering critical detection capabilities anytime, anywhere. Unlike older detection tools, FAID can recognize the basic chemical patterns found in fentanyl, which allows it to identify current and new versions of the drug.

With fentanyl being the leading cause of death among Americans aged 18 to 45 and over 4,000 potential analogs identified by the Department of Homeland Security, existing detection systems struggle to keep pace with this evolving threat. They rely on extensive libraries of synthesized analogs, leaving gaps in detection capabilities. In contrast, FAID can find fentanyl and its variations even in very small amounts, even when mixed with other substances. This technology, which has roots in two recent LDRD projects, is a significant step forward in chemical detection, helping to protect our military personnel, emergency responders, and police officers.

Low Coefficient of Thermal Expansion (CTE) Molecules to Resolve Thermal Expansion Problems in Polymers

Mechanical/Materials – Winner

Harsh, dynamic environments can wreak havoc on applications, especially when multiple types of materials are bonded together, and they expand and contract at different rates due to temperature changes. This mismatch in thermal expansion can lead to failures in products before their expected end-of-life. Currently, manufacturers often add fillers to help reduce this mismatch, but this approach only partially solves the problem and can create other issues, for example, with processing.

Sandia partnered with the University of Texas at Austin and scale-up partner Tetramer Technologies, Inc. to develop a new solution. They created a special molecule that can adjust thermal expansion properties of polymers/plastics because of its chemical structure. Polymers are like beaded necklaces in that they are made up of several different beads (monomers) strung together. By replacing some of those beads with the special molecule, the polymer can better match the expansion rates of different materials without needing fillers.

This innovation, which is rooted in two LDRD projects, is a significant advancement in addressing the thermal expansion mismatch between polymers and metals or ceramics, a common issue in the industry. Traditionally, addressing this mismatch requires a lot of time and effort, often involving expensive or specialized materials. By using this new molecule, which is targeted for use in more affordable polymers, manufacturers can reduce costs and potentially eliminate the need for harmful materials, making their products safer and more efficient.

Hafnia Gate Dielectrics for Energy Conversion

Process/Prototyping – Winner

With the rapid expansion of AI and data centers, as well as global electrification, the electrical grid faces immense pressure. High-power semiconductors are needed to minimize energy losses. Over $2 trillion of electricity is processed annually in the U.S., and power electronics are estimated to consume 30-40% of this energy. A one percent reduction in losses could save $500 million to $1 billion annually. Advancing power semiconductor technologies is critical for a more efficient and sustainable energy infrastructure.

The introduction of hafnia gate dielectrics for WBG semiconductors represents a groundbreaking shift in value for cost-sensitive applications, particularly in the transportation and smart grid sectors. This advancement signifies a transformative leap in capability and cost efficiency that is unlikely to be matched by conventional scaling over the next 15 years.

As high-k gate dielectrics’ advantages are realized, large-scale markets in solid-state electrical substations, diverse transportation modes (land, sea, and air), and rugged applications in harsh environments will emerge. This pioneering material is the first commercially available hafnia gate dielectric for WBG semiconductors and is ready for immediate production.

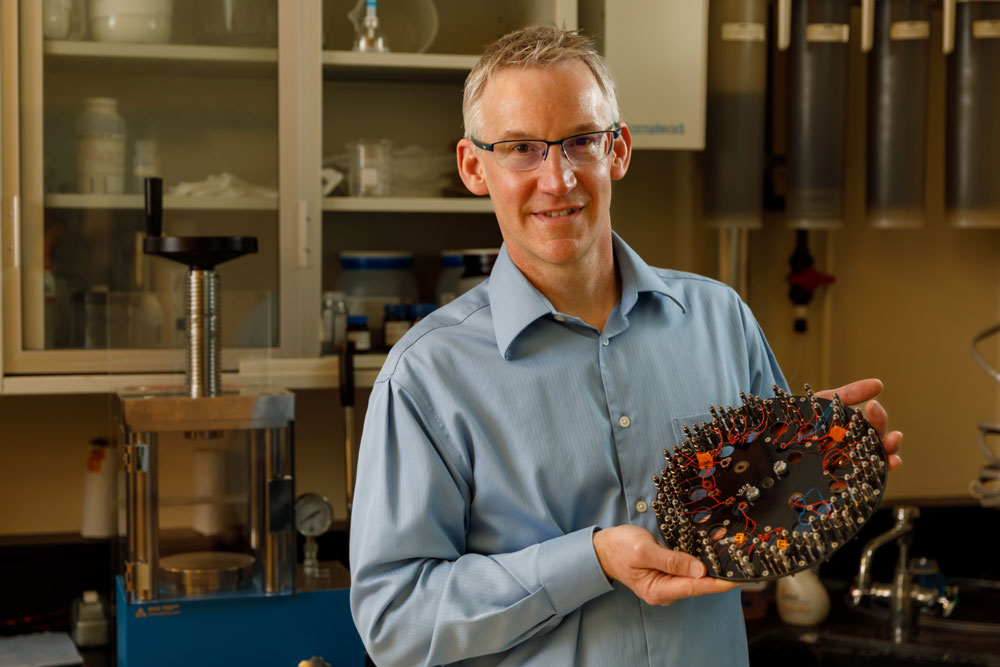

Bleeding Materials & Enclosures

Tamper-indicating seals are widely used across industries from over-the-counter medication bottles to containers protecting national security materials. The Bleeding Materials & Enclosures product uses a completely new approach to fabricating custom tamper-indicating enclosures using commercial-off-the-shelf materials that allow rapid and conclusive inspections for potential tamper or damage. The “wow” factor of the material is that it irreversibly turns from multi-colored to black upon tamper, and the reaction is visually obvious.

The dramatic color change begins at the site of the damage or penetration and spreads with time, similar to bruising or bleeding. An additional feature is that the multi-colored beads act as a mechanism to prevent counterfeit or substitute, as they randomly form patterns in the material that can be compared before and after deployment. Any damage or penetration will disturb the spatial location of the beads, and an adversary attempting to counterfeit or substitute the enclosure would find it extremely difficult to arrange the beads in the same pattern. All of these features are created using common, affordable materials.

The bruising materials research was funded by Sandia’s LDRD program. Further development and device prototyping were funded by the NNSA.

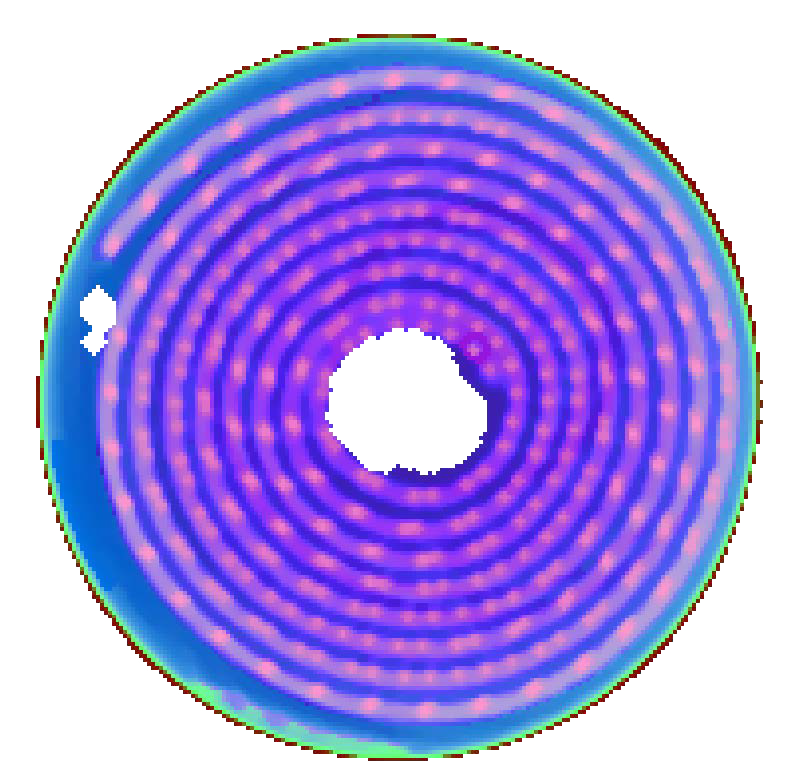

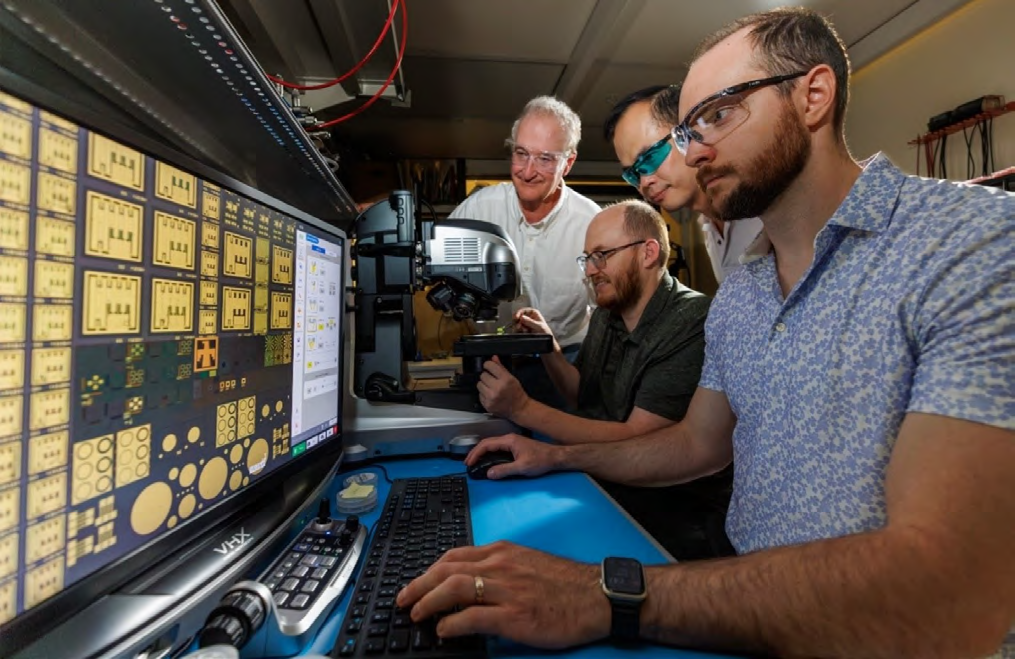

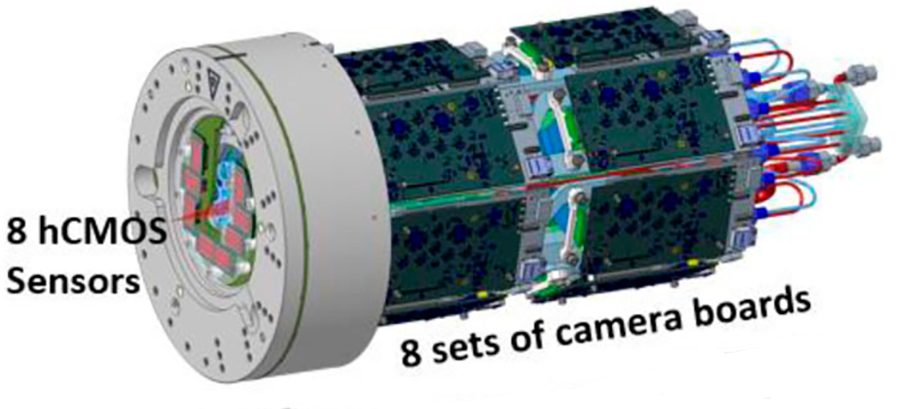

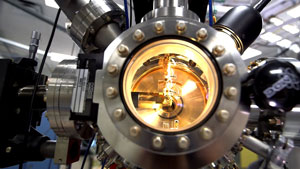

Time-Resolved Diffraction for NIF (National Ignition Facility)

Mechanical/Materials – Winner

Led by Lawrence Livermore National Laboratory

Co developers: Sandia, Advanced hCMOS Systems

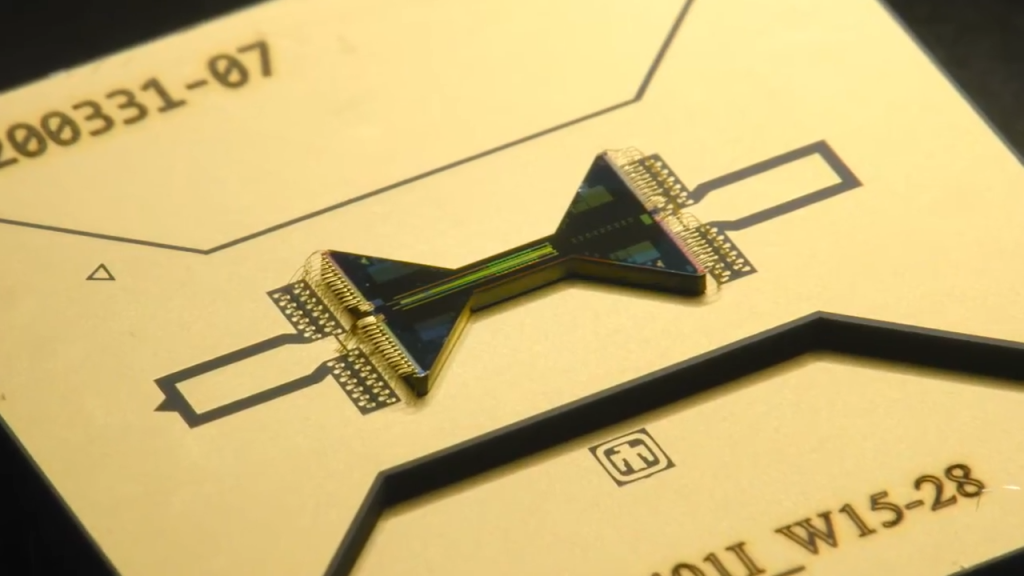

Measuring the properties of materials under extreme conditions, such as very high pressures (over 1 million bars), is important for various fields of High Energy Density (HED) research. This includes studying the dynamics of the Earth’s core and improving fusion ignition at facilities like the National Ignition Facility (NIF). To create accurate physical models and simulations, precise information is needed about how materials behave under these extreme conditions.

The key properties of materials—like their strength, how easily they can be compressed, and their ability to conduct heat—are heavily influenced by their structural phase. Therefore, it is crucial to measure not only the density of the materials but also their phase and how they respond to changes in pressure. This comprehensive understanding helps researchers make better predictions and advancements in their work.

The solution selected as the basis for the new time-resolved detector is the nanosecond-gated hybrid CMOS (hCMOS) sensors from Sandia that can capture multiple frames of diffraction data on a single laser-compression experiment. LDRD investments from the past and other NNSA support allowed scientists and engineers at Sandia to contribute to this effort.

Previous winners

Low-cost Direct Air Capture of CO2 with Clay Nanointerlayer

Machinable, Larger-Scale, Self-Healing RHEAs for Energy and Aerospace Applications

Pre-Symptomatic Volatile Organic Compounds Detector of Seizure Events

ETA Optics Studio

Materials Learning Algorithms

Materials Data-Driven Design

PowerModelsONM

Electro3D

Ultra-Stable Thermally Excellent Advancements in Material Strength

Iron Nitride Soft Magnetics

Automated Threat Estimator for Networks and Applications

Proactive Intrusion Detection and Mitigation System

MOSAICS

Secure-Firmware Over-the-Air (S-FOTA) Update

Quantum Scientific Computing Open User Testbed

Rapidly Producible/Reusable N95 Respirator (RAPTR)

WEC-Sim

Slycat: Scalable Ensemble Analysis and Visualization

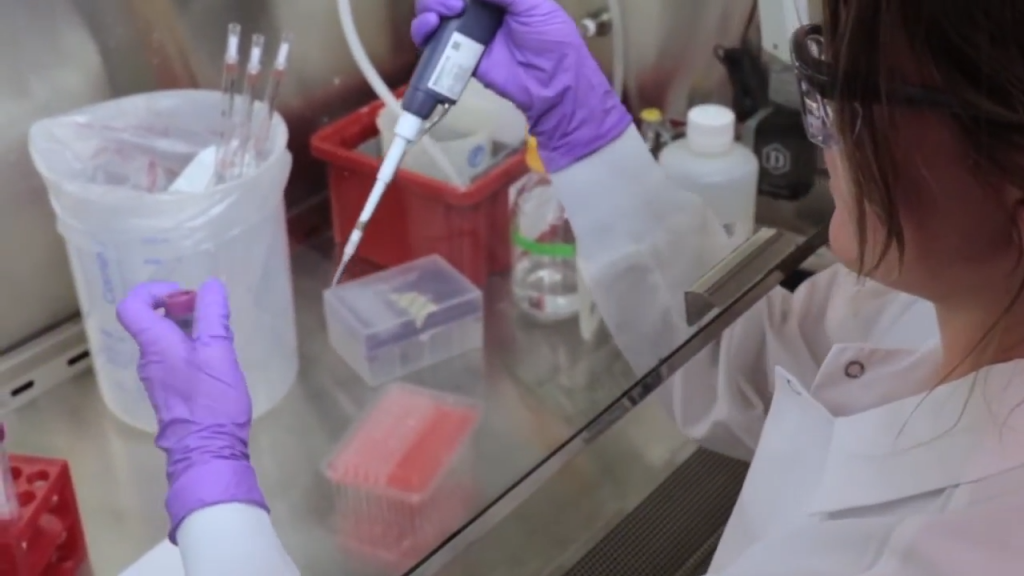

Antibody Therapeutic for SARS-CoV-2

AeroMINE — Stationary Harvesting of Distributed Wind Energy

Binary Solvent Diffusion for Fabrication of Large Nanoparticle Supercrystals

Tracktable

HECATE – Software Supply Chain and Assurance Platform

(IDAES) Process Systems Engineering Computational Framework

XRPBS: X-ray Polarizing Beam Splitter

Legion: A Data-Centric Programming System

ADDSec: Artificial Diversity and Defense Security

CHIRP: Cloud Hypervisor-forensics and Incident Response Platform

MIRaGE: Multiscale Inverse Rapid Group-theory for Engineered-metamaterials

NEDs: High-Performance Nanoantenna-Enabled Detectors

Detergent-assisted Fabrication of Multifunctional Nanomaterials

Large Field-of-View Bench Top 3-D X-Ray Phase Contrast Imaging System

SWiCK Zoom

LAMMPS: Atomistic Simulation of Materials

Power API

High-fidelity Adaptive Deception & Emulation System (HADES) Platform

SolidSense “Gas Analyzer on a Chip”

Control System for Active Damping of Inter-area Oscillations

Microgrid Design Toolkit

Ultra-Wide Bandgap Power Electronic Devices

Falling Particle Receiver for Concentrated Solar Energy

Ultra-fast X-ray Imager (UXI)

Transceiver for Quantum Keys and Encryption (T-QUAKE)

Pyomo v4.1

Stress-Induced Fabrication of Functionally Designed Nanomaterials

Precision High Power Battery Tester

CO2 Memzyme

LED Pulser

Integrated Circuit Identification

Lightweight Distributed Metric Service

Silicon Carbide JFET Switch

Portable Diagnostic Device for Bacillus Anthracis Detection in Ultra-Low Resource Environments

GOMA 6.0

Triple Harvesting Plastic Scintillators

Membrane Projection Lithography

Mantevo Suite 1.0

Solar Glare Hazard Analysis Tool (SGHAT)

Microsystems Enabled Photovoltaics

Neutristor

Sandia Digital Microfluidic Hub

Sandia Cooler

Biomimetic membranes for water purification

Microresonator filters and frequency references

Ultra-high-voltage Silicon Carbide Thyristor

CANARY: Event Detection Software

Multifunctional Optical Coatings

Acoustic Wave Biosensors, Rapid Point-of-Care Medical Diagnostics

Micro Power Source

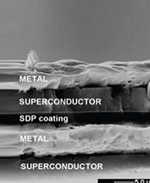

Solution Deposition Planarization (SDP), Superconductor Substrate Preparation Process

Ultralow-Power Silicon Microphotonic Communications Platform

Hyperspectral Confocal Fluorescence Microscope System

NanoCoral TM

Artificial Retina Project

SiCPower Module

Catamount N-Way (CNW) Lightweight Kernel

XyceTM Parallel Electronic Simulator 4.0.2

Silicon Micromachined Dimensional Calibration Artifact for Mesoscale Measurement Machines

Superhydrophobic Coating

ArcSafe© with Pulsed Arrested Spark Discharge

Mode-Filtered Fiber Amplifier

ElectroNeedle™ Biomedical Sensor Array

Self-Assembling Process for Fabricating Tailored Thin Films