Roadrunner 3D, a subsidiary of Westwind Computer Products, specializes in advanced manufacturing of alloys and plastics, and is currently partnering with Sandia National Laboratories in the area of refractory high-entropy alloys. RHEAs are high-temperature, high-strength materials that exceed the performance of superalloys such as Inconels and high-grade stainless steels, making them ideal for high-temperature applications such as energy (e.g., nuclear reactors, fission, and concentrated solar) and aerospace.

“We are pleased with the results of this TRGR project. As an innovator, we’re excited to introduce new alloys to manufacturers. We look forward to refining the solutions so we can take advanced BJG-RHEA materials to a broader market.”

Steve Hull

President

Westwind Computer Products Inc.

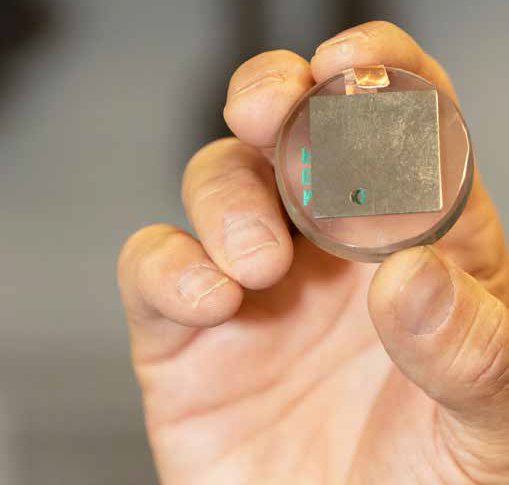

With this TRGR Project, Sandia Researcher Sal Rodriguez was successful in using the binder jetting (BJG) additive manufacturing process for RHEAs—the first time this has been accomplished. The development of this new manufacturing process included determining values for variables such as what temperature, pressure, time, and binding agent would work best.

Two different high-density alloys were produced for applications in aerospace and energy, and sample parts made from the alloys were tested. Both alloys were determined to be tough, homogenous materials that could be milled, drilled and polished. In the course of the TRGR Project, two technical advances were submitted, which may be patented in the future. With the prototypes tested and data on material properties collected, the TRL level of the BJG-RHEAs is now at 5.5. Westwind and Sandia look forward to future collaboration to advance the BJG-RHEA technology through the New Mexico LEEP Program. They are also working jointly on a Department of Energy Fusion Innovation Research Engine proposal. These collaborations will move the technology closer to market adoption.