4.28. Viscoplastic Foam Model

4.28.1. Theory

The viscoplastic foam model is used to model the rate (and temperature) dependent crushing of foams [[1]]. It is based on an additive split of the rate of deformation into an elastic and plastic portion

The stress in the material is due strictly to the elastic portion of the rate of deformation so that

where \(\mathbb{C}_{ijkl}\) are the components of the fourth-order, isotropic elasticity tensor. The stress rate is arbitrary, as long as it is objective. Two objective stress rates are commonly used: the Jaumann rate and the Green-McInnis rate. For problems with fixed principal axes of deformation, these two rates give the same answers. For problems where the principal axes of deformation rotate during deformation, the two rates can give different answers.

To describe the rate-dependent response, an over-stress-type yield function is used. Specifically, the rate-independent foam plasticity yield function

where \(\sigma^*\) is the effective stress given by

In (4.134), \(\bar{\sigma}\) is the von Mises effective stress (\(\bar{\sigma}=\sqrt{\frac{3}{2}s_{ij}s_{ij}}\)) and \(p\) is the pressure resulting from a stress decomposition of the form,

Furthermore, \(a\) and \(b\) are state variables that are functions of the absolute temperature, \(\theta\), and maximum solid volume fraction, \(\phi\), and are defined as

In (4.135) and (4.136), the functional forms are chosen to provide flexibility in terms of representation. To this end, \(f_a\) and \(f_b\) default to constant values of one and the expression reduce to legacy analytical functions. This both provides for backward compatibility with previous user input decks while allowing for user defined definitions. Further, if \(A_1\left(\theta\right)=0\), \(a\left(\theta,\phi\right)=A_0\left(\theta\right)f_a\left(\phi\right)\); a multiplicative decomposition of dependencies.

The temperature dependent material properties in the preceding relations are all defined as, \(A_{0}\left(\theta\right)=A_0h_{A_0}\left(\theta\right)\) where \(A_0\) is the reference material parameter and \(h_{A_0}\left(\theta\right)\) is the relative value as a function of temperature. In addition to the \(a\) and \(b\) state variables, the Young’s modulus and Poisson’s ratio are also functions of the absolute temperature. The latter may be written as \(\nu\left(\theta\right)=\nu h_{\nu}\left(\theta\right)\) while the former is also dependent on the maximum volume fraction of solid material and is given as \(E\left(\theta,\phi\right)=Eh_E\left(\theta\right)f_E\left(\phi\right)\).

The maximum volume fraction of solid material, \(\phi\), is given by

where \(\tilde{\phi}\left(t\right)\) is the current volume fraction of solid material and is defined as,

with \(\phi_0\) being the initial solid volume fraction and \(\varepsilon^{\text{p}}_v\) is

During inelastic deformation (\(f>0\)), the corresponding rate of plastic deformation is given in a Perzyna-type form as,

where \(h\left(\theta\right)\) and \(n\left(\theta\right)\) are the flow rate and power exponent respectively. The inelastic flow direction, \(g_{ij}\), is given as a linear combination of the associated (with respect to (4.133)), \(g^{\text{a}}_{ij}\), and radial, \(g^{\text{r}}_{ij}\),

The directions \(g^{\text{a}}_{ij}\) and \(g^{\text{r}}_{ij}\) are given by

in Equations (4.129) and (4.130),

respectively. In this model, the flow rule weight, \(\beta\), may be specified as either a constant value or as a function of the maximum solid volume fraction (\(\beta=\beta_0f_{\beta}\left(\phi\right)\)).

4.28.2. Implementation

As the viscoplastic foam model is a time-dependent, hypoelastic model it is integrated using an explicit, forward Euler scheme. Given this approach, a critical time step for stability is computed based on the shear strength, current modulus, and deviatoric deformation rate. If the input time step is acceptable, the new material state at time \(t=t_{n+1}\) is computed. On the other hand, if the time step is too large a series of sub-increments are used. In this case, the total time step \(\Delta t\) is subdivided into \(N\) sub-increments. Each such sub-interval (denoted by \(k\)) has a time increment \(\delta t^k\) such that \(\Delta t = \sum_{k=1}^{N}\delta t^k\) and the forward Euler time stepping scheme is performed over each sub-interval until the desired material state at time \(t_{n+1}\) is determined. For the case of temperature dependent variables (e.g. the Poisson’s ratio \(\nu\)), the value at the start of the sub-increment is determined by linearly interpolating over the total time step,

where \(\Delta t^k\) is the current sub-increment time, \(\Delta t^k=\sum_{r=1}^k\delta t^r\). For simplicity, in the remainder of this section it is assumed that the input time step is acceptable and only a single increment is needed. If additional sub-increments are needed, the below steps would be repeated \(N\) times with time intervals of \(\delta t^k\).

Noting the forward Euler approach adopted in this formulation, the first step is to determine the temperature (and solid volume fraction) dependent model parameters (\(E,~\nu,~A_0,~A_1,~B_0,~B_1,~h\) and \(n\)). With the parameters established, state variables \(a\) and \(b\) are easily determined through (4.135) and (4.136), respectively, enabling the calculation of the effective stress via (4.134). The effective inelastic (plastic) strain rate, \(\dot{\bar{\varepsilon}}^p\), is then given as,

with \(\left< \right>\) being the Macaulay brackets such that,

Knowing the magnitude of the rate of inelastic deformation, the change in deviatoric and hydrostatic stresses is simply,

where \(d_{ij}\) is the total unrotated rate of deformation, \(\hat{x}_{ij}\) denotes the deviatoric portion of tensor \(x_{ij}\), and \(d^{\text{p}}_{ij}\) is the plastic rate of deformation given by,

In (4.138), \(g_{ij}\) is the inelastic flow direction and can be calculated via (4.137).

An additional comment is needed with respect to accounting for temperature and solid volume fraction dependence in the shear and bulk moduli. This careful consideration is necessary due to the fact that the temperature dependence is only given with respect to the elastic moduli and Poisson’s ratio. As such, the shear and bulk moduli inherit the associated dependencies and are calculated for isotropic elastic relations. For the bulk moduli, this leads to an expression of the form,

The updated stress state is then easily computed by explicitly integrating the established expressions. Specifically,

with \(\mu_n\) and \(K_n\) representing \(\mu\left(\theta_n,\phi_n\right)\) and \(K\left(\theta_n,\phi_n\right)\), respectively, and \(T_{ij}\) being the unrotated stress.

4.28.3. Verification

The viscoplastic foam model was verified in both uniaxial and hydrostatic compression. The material properties and model parameters for both of these investigations are given in Table 4.43. As both loadings are isothermal, temperature dependence is neglected in the relevant model parameters. Furthermore, analytical solutions could not be found directly, so semi-analytical solutions were found.

\(E\) |

4,807 psi |

\(A_{0}\) |

63.03 psi |

\(\nu\) |

0.33 |

\(A_{1}\) |

7000 psi |

\(h\) |

-8.12 |

\(A_{2}\) |

3.7878 |

\(n\) |

2 |

\(B_{0}\) |

93 psi |

\(\beta\) |

0.9 |

\(B_{1}\) |

1483.4 psi |

\(\phi_{0}\) |

0.1148 |

\(B_{2}\) |

3.7878 |

4.28.3.1. Uniaxial Compression

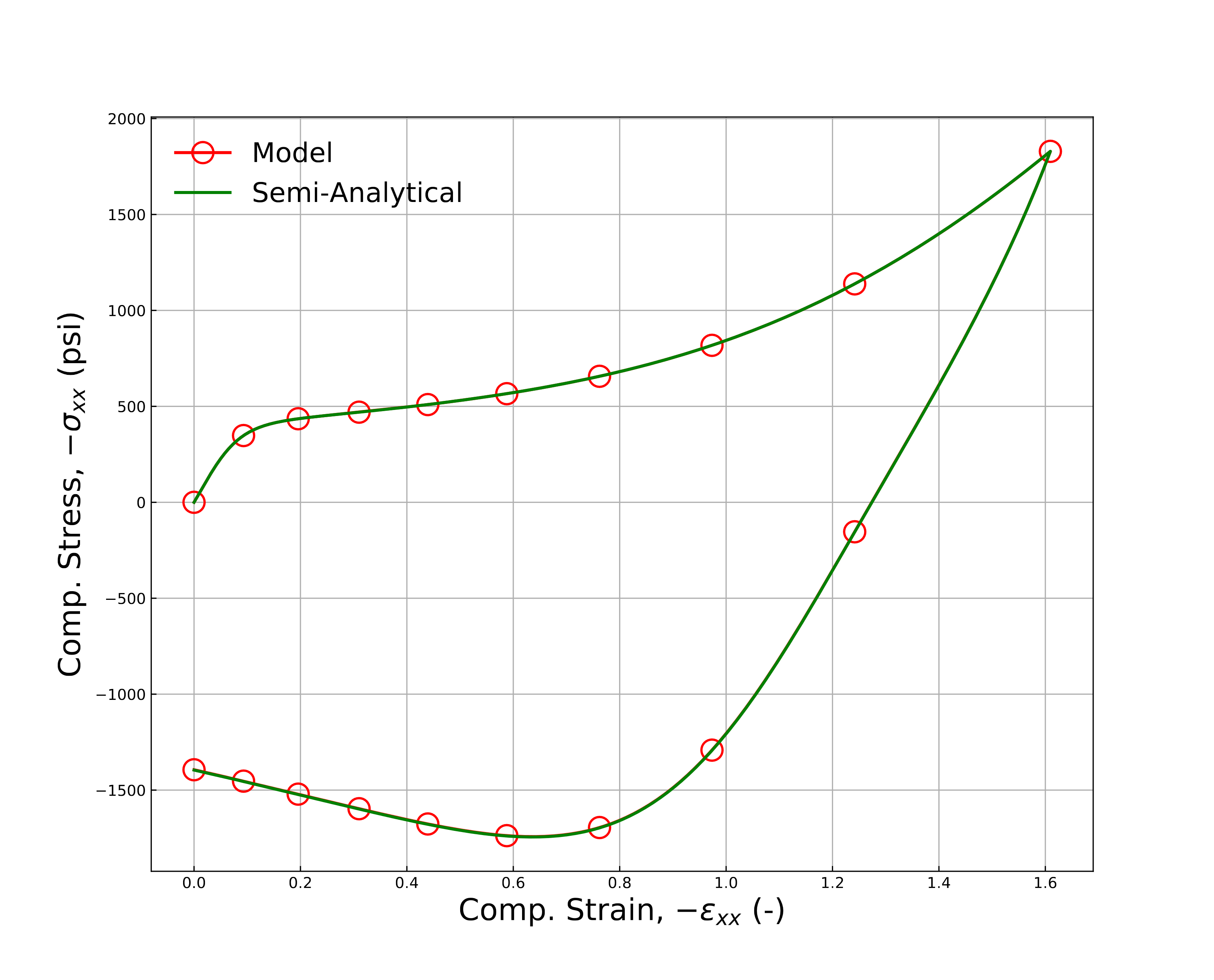

To obtain a semi-analytical solution for the uniaxial compression test, the model was reduced to a one-dimensional form and then numerically integrated. The results obtained from the implemented model and the semi-analytical solution are shown below in Fig. 4.124.

Fig. 4.124 Verification of the viscoplastic foam model in uniaxialcompression showing the axial stress as a function of thelogarithmic strain

4.28.3.2. Hydrostatic Compression

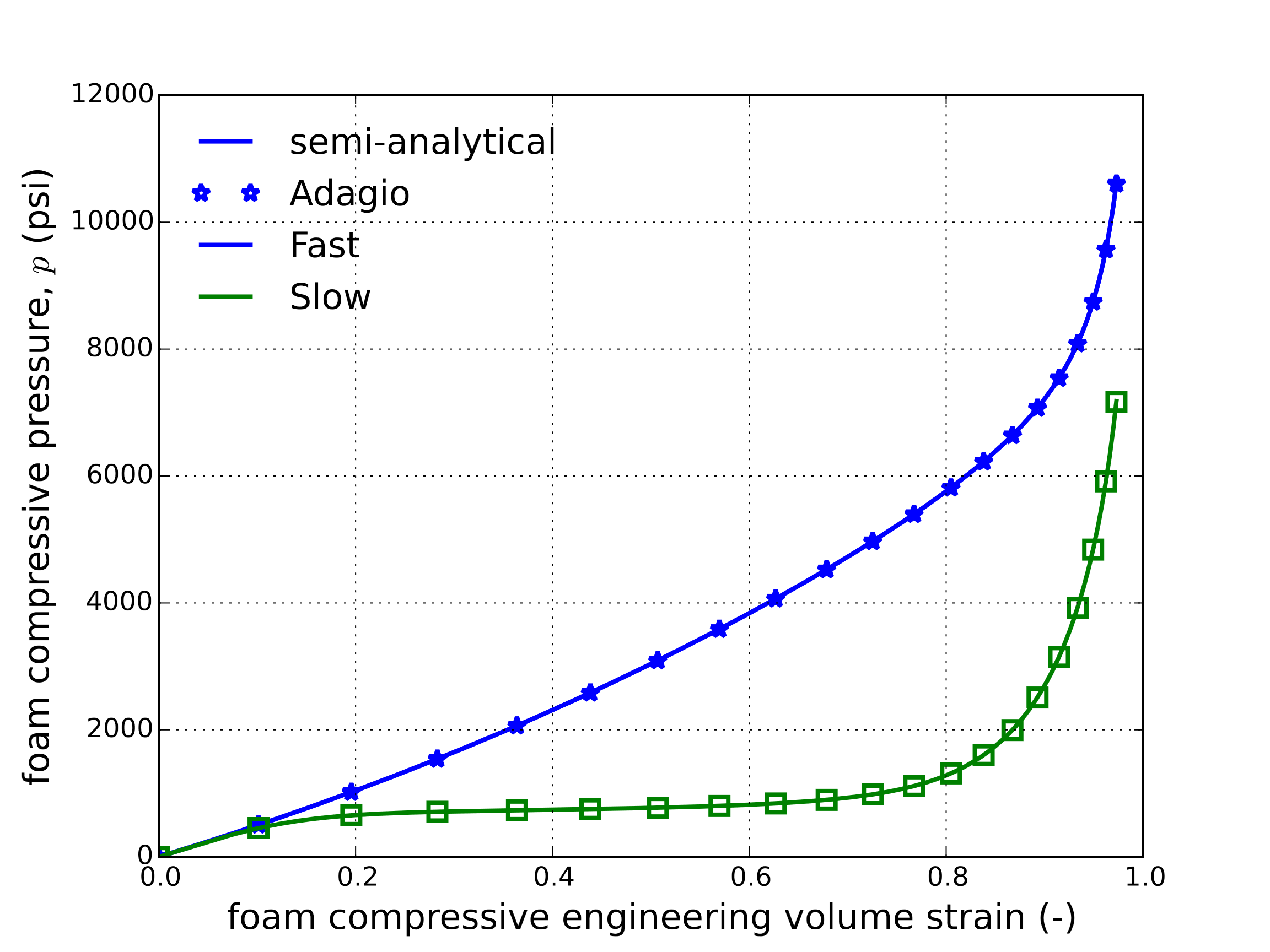

The response of the model through hydrostatic compression. To this end, a displacement of the form \(u_i=\lambda\left(t\right)\) is considered. The applied displacement scales linearly from \(\lambda=0\) at \(t=0.0\) to \(\lambda=-0.7\) at \(t=t_{\text{max}}\). Rate-dependent effects are considered through the use of two cases each with a different \(t_{\text{max}}\). Creatively denoted Fast and Slow, the two cases correspond to \(t_{\text{max}}=1\) s and \(t_{\text{max}}=100\) s, respectively. With such a displacement field, the engineering volume strain, \(\varepsilon_{\text{V}}\), is simply \(\varepsilon_{\text{V}}=\left(1+\lambda\right)^3-1\). Additionally, the stress state reduces trivially to \(\sigma_{ij}=-p\delta_{ij}\).

Given the rate-dependent overstress form of the constitutive model, an analytical solution is not readily available. Therefore, a semi-analytical analysis using a model reduction specialized for hydrostatic loadings is considered. Specifically, noting \(s_{ij}=0\), the overstress reduces to,

Furthermore, the associated and radial flow direction vectors simplify to the same form and are given as,

where \(\text{sgn}\left(p\right)\) is the sign of \(p\). The semi-analytical (integrated in a forward Euler fashion) and numerical results are presented in Fig. 4.125.

Fig. 4.125 Pressure-engineering volume strain results of viscoplastic foam model subjected to a hydrostatic loading at both fast and slow rates determined semi-analytically and numerically.

4.28.4. User Guide

BEGIN PARAMETERS FOR MODEL VISCOPLASTIC_FOAM

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

FLOW RATE = <real>

POWER EXPONENT = <real>

BETA = <real> (1.0)

PHI = <real>

SHEAR STRENGTH = <real> (1.0)

SHEAR HARDENING = <real> (0.0)

SHEAR EXPONENT = <real> (1.0)

HYDRO STRENGTH = <real> (1.0)

HYDRO HARDENING = <real> (0.0)

HYDRO EXPONENT = <real> (1.0)

YOUNGS FUNCTION = <string>

POISSONS FUNCTION = <string>

SS FUNCTION = <string>

SH FUNCTION = <string>

HS FUNCTION = <string>

HH FUNCTION = <string>

RATE FUNCTION = <string>

EXPONENT FUNCTION = <string>

STIFFNESS FUNCTION = <string>

SHEAR HARDENING FUNCTION = <string>

HYDRO HARDENING FUNCTION = <string>

BETA FUNCTION = <string>

END [PARAMETERS FOR MODEL VISCOPLASTIC_FOAM]

In the above command blocks:

Since the model requires functions to describe the temperature dependence of the elastic modulus and Poisson’s ratio, it is recommended that one inputs these properties at some reference temperature. However, any two of the elastic constants can be used for input.

The reference value for the flow rate, \(h\), is defined with the

FLOW RATEcommand line.The reference value of the over-stress exponent, \(n\), is defined with the

POWER EXPONENTcommand line.The user-defined scalar scaling between associated and radial flow, \(\beta\), is defined with the

BETAcommand line.The initial volume fraction of solid material, \(\phi_0\), is defined with the

PHIcommand line.The reference value for the shear strength, \(A_{0}\), is defined with the

SHEAR STRENGTHcommand line.The reference value for the shear hardening modulus, \(A_1\), is defined with the

SHEAR HARDENINGcommand line.The shear hardening exponent, \(A_{2}\), is defined with the

SHEAR EXPONENTcommand line.The reference value for the hydrostatic strength, \(B_{0}\), is defined with the

HYDRO STRENGTHcommand line.The reference value for the hydrostatic hardening modulus, \(B_{1}\), is defined with the

HYDRO HARDENINGcommand line.The hydrostatic hardening exponent, \(B_{2}\), is defined with the

HYDRO EXPONENTcommand line.The user-defined and normalized function that gives the elastic modulus as a function of temperature, \(h_{E}(\theta)\), is defined with the

YOUNGS FUNCTIONcommand line.The user-defined and normalized function that gives the Poisson’s ratio as a function of temperature, \(h_{\nu}(\theta)\), is defined with the

POISSONS FUNCTIONcommand line.The user-defined and normalized function that gives the shear strength as a function of temperature, \(h_{A_0}(\theta)\), is defined with the

SS FUNCTIONcommand line.The user-defined and normalized function that gives the shear hardening modulus as a function of temperature, \(h_{A_1}(\theta)\), is defined with the

SH FUNCTIONcommand line.The user-defined and normalized function that gives the hydrostatic strength as a function of temperature, \(h_{B_0}(\theta)\), is defined with the

HS FUNCTIONcommand line.The user-defined and normalized function that gives the hydrostatic hardening modulus as a function of temperature, \(h_{B_1}(\theta)\), is defined with the

HH FUNCTIONcommand line.The user-defined and normalized function that gives the flow rate as a function of temperature, \(h_{h}(\theta)\), is defined with the

RATE FUNCTIONcommand line.The user-defined and normalized function that gives the over-stress exponent as a function of temperature, \(h_{n}(\theta)\), is defined with the

EXPONENT FUNCTIONcommand line.The user-defined and normalized function that gives the elastic modulus as a function of maximum solid volume fraction, \(f_{E}(\phi)\), is defined with the

STIFFNESS FUNCTIONcommand line.The optional user-defined function that gives the shear strength as a function of the maximum solid volume fraction, \(a\left(\phi\right)\), is defined with the

SHEAR HARDENING FUNCTIONcommand line. Note, if this function is defined theSHEAR STRENGTH,SHEAR HARDENING, andSHEAR EXPONENTvalues should not be specified.The optional user-defended function that gives the hydrostatic strength as a function of the maximum solid volume fraction, \(b\left(\phi\right)\), is defined with the

HYDRO HARDENING FUNCTIONcommand line. Note, if this function is defined theHYDRO STRENGTH,HYDRO HARDENING, andHYDRO EXPONENTvalues should not be specified.The optional user-defined function that gives the scaling between associated and radial flow as a function of maximum solid volume fraction, \(\beta\left(\phi\right)\), is defined with the

BETA FUNCTIONcommand line. Note, if this function is defined theBETAvalue should not be specified.

Output variables available for this model are listed in Table 4.44.

Name |

Description |

|---|---|

|

number of sub-increments |

|

inelastic volumetric strain, \(\varepsilon^{\text{p}}_v\) |

|

effective inelastic strain rate, \(\dot{\bar{\varepsilon}}^{p}\) |

|

maximum volume fraction of solid material, \(\phi\) |

|

shear strength, \(a\) |

|

hydrostatic strength, \(b\) |

|

elastic stiffness as a function of \(\phi\) |