Peer review meeting draws praise for Labs practices

In November, Sandia and the NNSA Sandia Field Office hosted senior leaders from DOE, the NTESS board of managers and the National Security Enterprise for a mandated NNSA Governance Peer Review that took an in-depth look at Sandia operations and management, and included meetings with Labs mission and support organizations and members. In its executive summary, the peer review team noted several best practices, including transparency with governing bodies, streamlined policies and processes, emphasis on safety, security and ethical behavior, an engaged board and a trusted relationship with SFO. (9200)

Common Engineering Environment cuts licensing costs

The Common Engineering Environment grew significantly under the new financial simplification model, while costs remained relatively low. Subscriptions to CEE services grew 74 percent with only an 8.6 percent increase in maintenance costs. The program spent approximately $1.5 million on new licenses that would have cost approximately $13 million if purchased individually. Efficiencies are realized by concurrent software licenses, active monitoring of license use and economies of scale. CEE enables technically creative work in a disciplined, common environment, which promotes increased quality and usability. (9300)

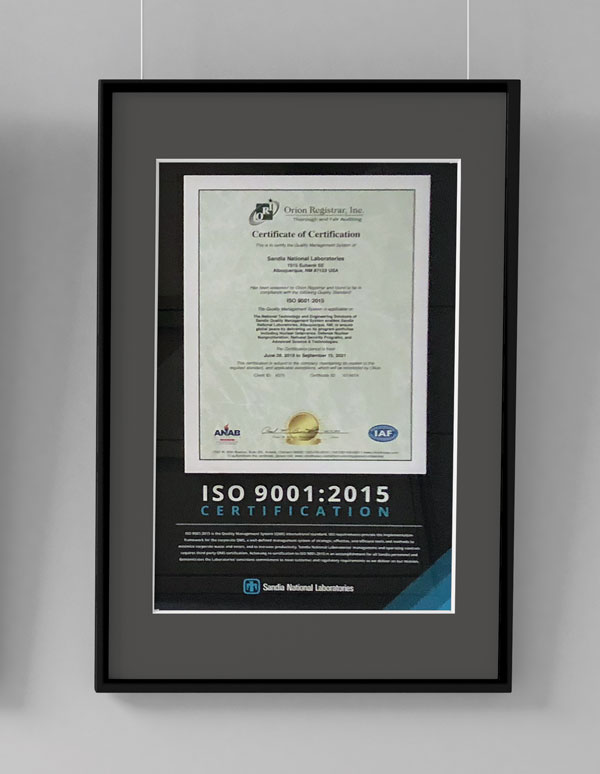

Quality Assurance team aces audit

Quality Assurance teamed with subject matter experts from across the Labs to complete the ISO 9001:2015 certification audit for Sandia with zero non-conformities and only a handful of opportunities for improvement. The audit moved Sandia from the 2008 version of the ISO standard to the expanded 2015 version. Required by the Labs’ contract, the annual audit assures customers that Sandia’s work consistently produces products and services that meet customer and regulatory requirements. (9100)

System for performance analysis improved

Sandia improved its Contractor Assurance System to provide more appropriate data and deeper performance analysis. Examples include deploying an enterprise risk management framework, initiating the executive risk review board and engaging with senior leadership and the NTESS board of managers to establish a set of Labs-level risks; improving processes for risk and issues management and replacing non-integrated assurance tools with an enterprise platform; deploying an assessor qualification program; and establishing a Labswide requirements management and traceability project to identify, communicate, actively manage and verify contractual requirements. (9200)

Prize garnered for improving marking across NNSA

The surety engineering and weapons quality NAP-24 stamping and marking policy improvements core team received a Defense Program Award of Excellence for teaming with seven NNSA sites to reduce policy complexity, which resulted in labor savings and cost avoidances estimated at over $10 million over the next five years. The integrated team addressed costs and waste associated with inconsistent stamping and marking that could trigger “false positive” quality alerts and re-work when assets are shipped between sites. (9400)

Quality audit responses on target for completion

The surety engineering and weapons quality team successfully led preparations for and completion of the QAS 1.0 audit, an end-to-end quality evaluation against the Nuclear Weapons Quality Standard (NAP-24A). Final audit results included 10 noteworthy observations (best practices), 11 remarks, and nine findings. All findings and remarks that require responses and corrective action are on target for on-time completion with monthly QAS 1.0 updates to the Sandia Field Office. (9400)

New system makes policies easier to use

A new Laboratory Policy System, introduced in August, makes it easier for the workforce to find, understand and apply the appropriate policies and processes that govern work. This four-year project reduced the volume of content in the policies tool by about 70 percent, cut the average time of discovery from 5 to 1.5 minutes and cut in half the average time to process policy changes. The corporate simplification effort was led by policy management in partnership with information technology, policy leads and subject matter experts from across the Labs. (9100, 10700)

Software upgrade improves weapons production

The logistics, accountability, planning, and scheduling phase 2 team modernized and significantly enhanced two outdated systems that support nuclear weapons production activities. Completed on time and within budget, the updated software is now used across the Nuclear Security Enterprise. As part of these projects, the team enabled several new capabilities, including Program Control Documents that provide authorization and directive schedules to program production agencies and cross-site scheduling that ensures components are shipped to the right location at the right time to meet PCD schedules. (9300)

Sandia/CA reduces data reviews by 90 percent

Sandia responded to an urgent request from the Kansas City National Security Campus to help reduce a backlog of test data transfer data reviews for components for the B61-12 Life Extension Program and W88 Alteration that had affected program schedule and cost. During the five-month collaboration, personnel from Sandia/California teamed with Kansas City to reduce the accumulated reviews from more than 550 to 60, a 90 percent reduction. The effort showcased clear communications and creativity, and set the stage for future partnership opportunities across the Nuclear Security Enterprise. (8100, 9400)