World’s fastest supercomputer based on low-power architecture

Astra, the first advanced prototype platform deployed to evaluate emerging high-performance computing technologies for NNSA’s stockpile stewardship mission, has achieved petaflops performance running an important industry-standard benchmark. This makes Astra the world’s fastest Arm-based platform on supercomputing’s TOP500 list. Astra has 5,184 central processing units, each with 28 cores, based on the Arm V8 64-bit core architecture. While Arm has been used extensively in low-power mobile computing, including cell phones and tablets, Astra is one of the first applications of Arm technology for supercomputing.

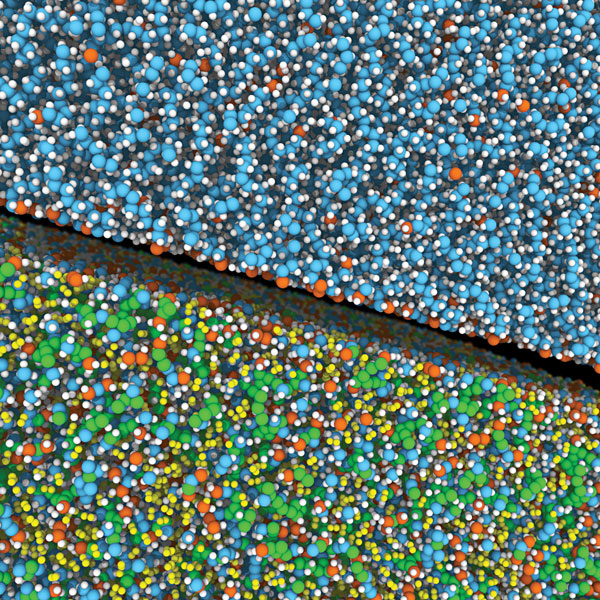

Unraveling how materials degrade in extreme conditions

From molecular simulation to experiments using the world’s brightest X-ray pulses at the Z Machine and National Ignition Facility, Sandia scientists are unraveling the mechanisms of material degradation under some of the most extreme heating conditions produced in laboratory environments. Accomplishments include new diagnostics to characterize rapid expansion of ablation plumes, the first fully-coupled, 3D mesoscale radiation/hydrodynamic simulation and the first implementation of chemistry models fully coupled with the multiphysics Sandia code, ALEGRA, for predicting polymer degradation in radiation environments. (Division 1000/LLNL/LANL/ANL/LDRD)

Models validate B61-12 Nose Bomb Subassembly design

An engineering sciences modeling and simulation team supported the design and qualification effort of the B61-12 Nose Bomb Subassembly (NBSA) Product Realization Team. The team developed and validated highly resolved models of the evolving and final NBSA design. The team applied the models over the range of conditions for impact speeds and angles and target hardness ranging from water to steel and concrete. The impact response of the NBSA was simulated through the model, allowing assessment of functional requirements over the full impact space. (Divisions 1000, 2000)

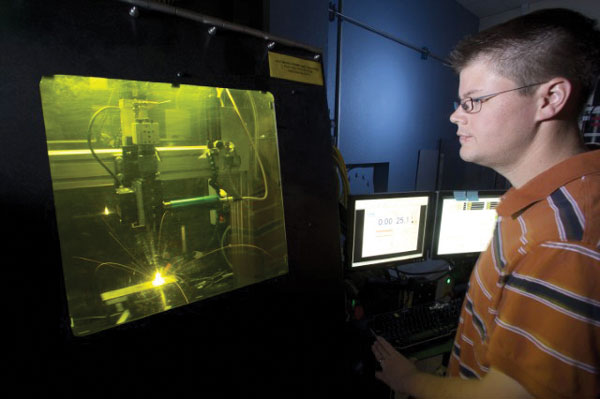

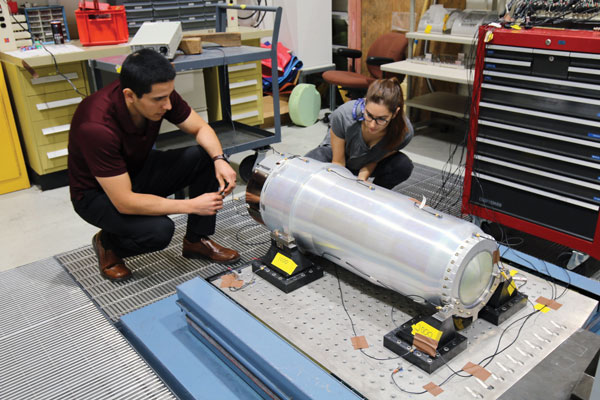

Material dynamic response experiments support life extension programs

DICE and STAR facilities have generated extensive data to support life extension programs for the B61-12 and other nuclear weapon systems. Experiments on Veloce, STAR, Thor and Z evaluated dynamic response of ceramic, composite and additively manufactured steel materials. Such data validate modeling predictions for performance of specific weapon components. DICE personnel recently provided on-site support to the National Security Campus at Kansas City that improved velocity measurements in impact fuze acceptance tests. (Divisions 1000, 2000)

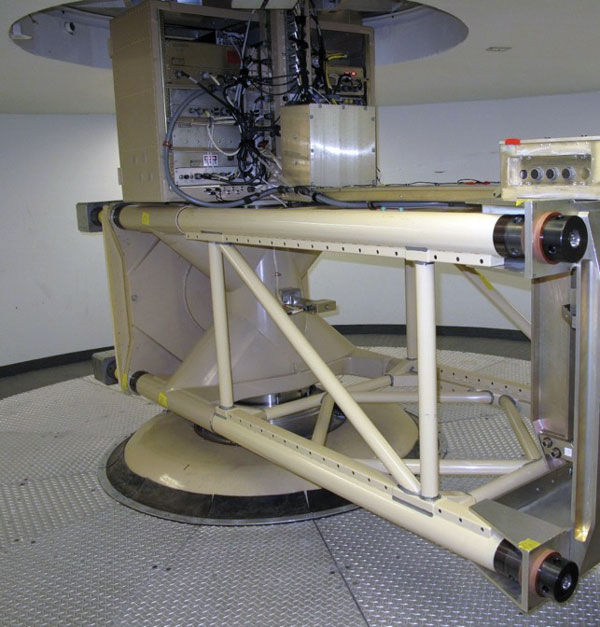

Surveillance centrifuge arm fully qualified

To sustain a critical national capability, the surveillance tester centrifuge team qualified the second surveillance large centrifuge (QU2639) with a new and redesigned centrifuge arm. The qualification engineering release marks the culmination of fabrication, integration and prove-in of the centrifuge system with the new arm. Data collected during performance and repeatability testing verify the system will meet all centrifuge testing requirements in a stable, reliable and predictable manner. (2000, 9000, 10000)

Record yields on Z machine advance fusion

The inertial confinement fusion program made major advances in magneto-inertial fusion research. Partly funded by ARPA-E, new experimental platforms were developed for both the Z pulsed power facility and the Omega laser facility at the University of Rochester. Using these platforms, researchers achieved record yields on Z that tripled the yield relative to the first experiments in 2014, and also demonstrated the same fusion concept on Omega using a factor of 1,000x less energy, strengthening the case for scaling this concept to a future facility.

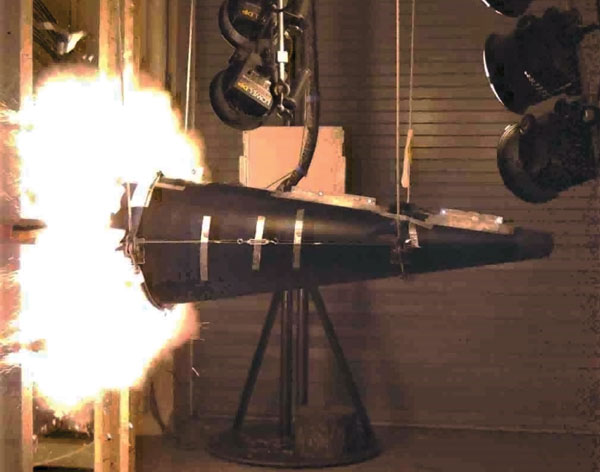

Explosive ignition model developed

As part of the DoD/DOE Joint Munitions Program, Sandia developed an ignition model for the LX-14 DOE/DoD explosive using the 3D finite element Sierra/Aria framework. Predicting the response of explosives in accidents is of mutual interest to Sandia and the U.S. Army for safety assessments, and the project furthered that aim significantly. The model was developed using various unique small-scale laboratory experiments of LX-14. A 3D full-scale model was successfully validated by the U.S. Army using experiments of a full-scale Tube-launched, Optically-tracked, Wire-guided (TOW) anti-tank missile warhead. (1000, 2000)

NNSA labs assess EMP threat to U.S. grid

Sandia, in partnership with Lawrence Livermore and Los Alamos national labs, completed a Tri-Lab Collective Assessment of Nuclear Electromagnetic Pulse Threats and Consequences to the U.S. Electric Grid. This assessment was requested by NNSA Administrator Lisa Gordon-Hagerty and delivered under the signatures of the three lab directors. The assessment provides detailed analyses and assessments of the threat, possible scenarios and potential responses of equipment and the grid, and discusses options for and issues with restoration, recovery and mitigation. The effort provided significant insight into this important national security topic. (1300, 2100, 5800, 6600, 8700, 8800)

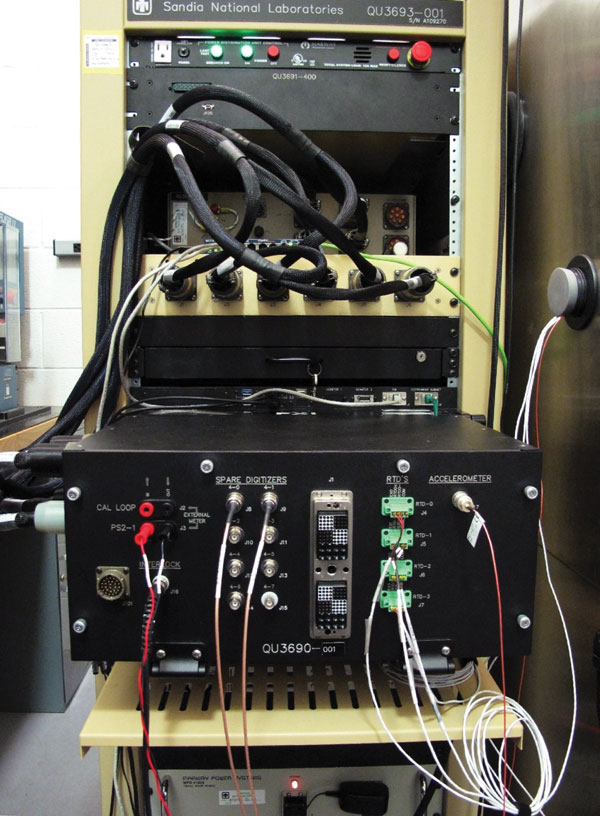

Labswide effort aids Kansas City tester development

In support of modernization program production, a Labswide effort directed by NNSA was quickly marshalled to augment tester development at the Kansas City National Security Campus. At its peak, more than 20 staff were provided to complete the development of testers that will be used to evaluate and accept components. Valuable contributions to the success of this effort came from technical, ES&H, program management, financial, legal and procurement organizations. (2000, 8000, 10000, 11000, 600)

Stronglink tester upgraded

In December 2017, the QU3663 Stronglink Safety Tester Phase II Upgrade was qualified for use in surveillance testing at the Weapons Evaluation Test Laboratory. This upgrade added the ability to test firing sets from multiple weapons systems at temperature extremes and has resulted in testing of many firing sets since the upgrade was completed. (2000, 8000, 9000)

B61-12 LEP hits major milestone

The B61-12 Life Extension Program successfully completed its final design review, meeting a major milestone and providing confidence the system is ready to proceed with final production qualification activities and produce the first unit in 2020. An independent team of 12 subject matter experts from the military and across the Nuclear Security Enterprise reviewed three years worth of electrical, mechanical, thermal and flight-testing data and analysis, as well as the program’s state of procedures, training and safety to determine that the B61-12 meets its requirements. (2000, 9000)

W88/Mk5 alterations complete final reviews

The W88/Mk5 weapon system program reached significant design maturity milestones for the two alterations (370 and 940) this past year. Alteration (ALT) 370 successfully completed final system and subsystem design reviews. ALT 940 also had a successful system final design review. These reviews were supported by design engineers at Sandia and across the Nuclear Security Enterprise, showcasing the excellent design engineering and technical basis compiled. The review panels found that the designs met requirements and can be produced. (1000, 2000, 5000, 8000, 9000)

Thermal analysis predicts B61-12 nuclear safety

Using modeling and simulation, Sandia worked with Los Alamos National Laboratory to provide predictions of B61-12 nuclear safety timelines used to quantify system safety for an external thermal insult. Thermal analysis models were applied by the B61-12 project to predict weapon nuclear safety for credible accident scenarios and weapon configurations not considered in qualification testing because of schedule and cost constraints. The abnormal thermal environment qualification and nuclear safety arguments were presented by systems engineering during B61-12 system final design review. (1000, 2000)

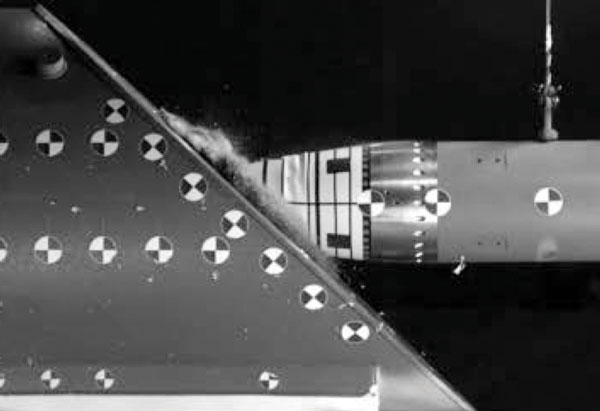

B61-12, engineering sciences simulate fuel-fire accidents

The B61-12 program partnered with engineering sciences to execute the final three abnormal environment tests in the system qualification plan: FastHeat2B, FastHeat3A and Impact3. The FastHeat tests were executed at the Cross Wind Test Facility and were designed to simulate fuel-fire accident scenarios. Impact3 was executed at the Aerial Cable Facility and was designed to simulate a C-17 cargo transport accident scenario. All three tests provided critical model validation data and provided evidence toward nuclear safety qualification for the B61-12. (1000, 1500, 2000)

W88 ALT 370 passes missile integration tests

The W88 ALT 370 program successfully completed the last of a series of missile system integration tests, in coordination with Lockheed Martin. The JT5ALT-17E series tests were successfully completed at three sites: Sandia/NM, the Eastern Range complex at Cape Canaveral and Lockheed Martin’s missile integration lab in Sunnyvale. The tests were the final missile system integration tests for the program, showing that the W88 ALT 370 Reentry Body meets all necessary requirements to integrate with the missile system. (2000)

AFAs delivered to U.S. Air Force

The Mk21 program successfully built, tested and delivered two flight-quality Arming and Fuzing Assemblies (AFAs) to the U.S. Air Force for real-world ICBM flight testing. Assembled at Sandia/NM, both AFAs underwent a rigorous series of mission simulations and testing. The primary AFA was integrated into the reentry vehicle configuration at Sandia/CA and delivered to Vandenburg Air Force Base. Once launched from Vandenburg, the FTU-1 flight mission will evaluate AFA performance during reentry. The other AFA was tested by the U.S. Air Force at Vandenburg to prove compatibility with existing tester interfaces. (2000, 8000)

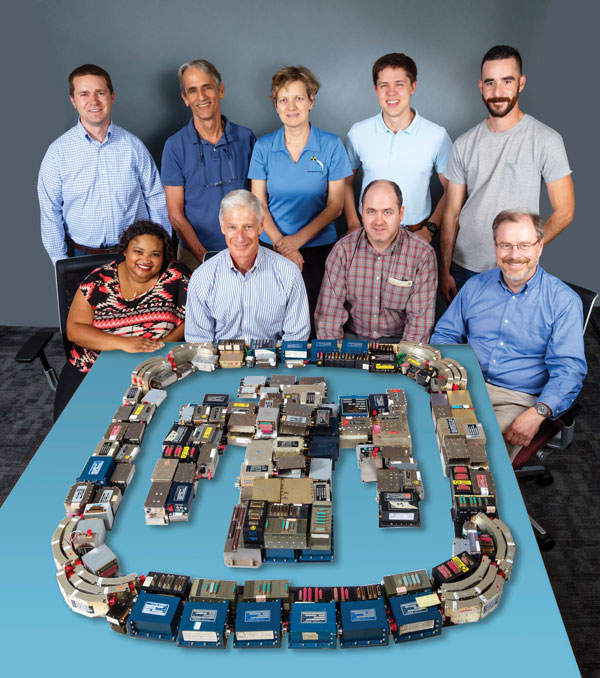

12 First Production Unit milestones achieved

In the summer of 2018, stronglinks and other major components of the W88 ALT 370 and B61-12 programs reached the milestone of First Production Unit. Together, the components comprise several hundred custom mechanical parts. The start of production culminates a multi-year development effort. Each of the components plays a vital role in energy isolation of the nuclear weapon to preclude unintended nuclear detonation. (1000, 2000, 9000, 10000).

Tonopah B61-12 team busy with flight, compatibility tests

In FY18, the B61-12 program, working with Sandia Tonopah Test Range, Sandia aircraft compatibility group and several U.S. Air Force partners, executed eight development flight tests (DFTs) as well as associated compatibility tests across three aircraft platforms with six distinct test assets. DFT missions on F-16C and F-15E aircraft were staged out of Nellis Air Force Base, while B-2A missions were staged out of Edwards Air Force Base. Completion of the grueling year of testing marks major progress in the B61-12 flight test qualification program. (2000)

Design tested in unique radiation environments

Intensive radiation testing was conducted for Sandia’s Mk21 Arming and Fuzing Assembly (AFA) design. In 2018, the AFA qualification team completed radiation environment tests (the RT-1 series) at Sandia’s HERMES and Saturn pulsed-power facilities. Performance and diagnostic information that could not have been collected elsewhere yielded critical insights into AFA performance in these environments. For these tests, the test team developed a customized dosimetry calibration unit to measure dose and dose rates. Additional testing at Sandia’s Annular Core Research Reactor is planned. (2000)

Product realization group makes advances

The component center has responded to various new Nuclear Security Enterprise production needs over the past year with great success in the areas of power sources, explosive components and unique, high-priority rapid-turn programs. To meet evolving rapid production needs of Sandia and the enterprise, the center established a dedicated organization for product realization that aims to integrate, adapt and grow Sandia product realization capabilities. The organization is anchored by a limited number of full-time staff with support from matrixed personnel from across the laboratory to meet a given production mission. (1000, 2000, 2500, 5000, 6000, 8000, 9000, 10000)

Mk21 Fuze Program completes tests

The Mk21 Fuze Program Thunderpipe Test Series was successfully executed in FY18. The series evaluated Mk21 vehicle response to representative hostile shock environments during the reentry phase. To reduce costs, the Thunderpipe team directly leveraged lessons learned from the W88 ALT 370 Program. The successful design, fabrication and assembly of three reentry vehicles culminated in the execution of seven outdoor explosive tests. The Thunderpipe test series marked a significant milestone for the U.S. Air Force customer and Mk21 Fuze Program. (1000, 8000)

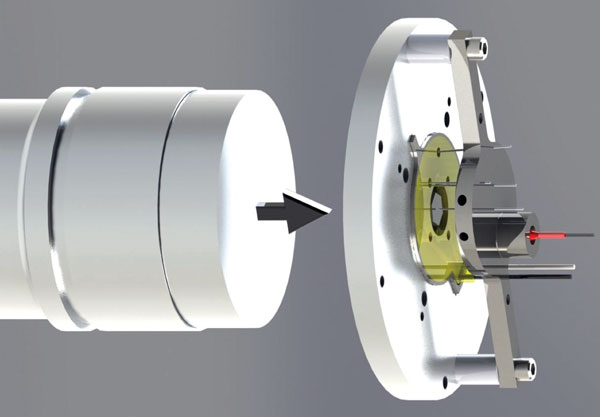

New electronic neutron generator qualified

Sandia’s modernized electronic neutron generator (ELNG), a nuclear weapon component that promotes the fission reaction, has been qualified for production and use. This represents a major milestone demonstrating the Labs not only can design the ELNG, but also manufacture it. This is the first redesign of the component since 1991, and the first ELNG built at Sandia since the closure of the Pinellas Plant. (1000, 2000, 8000, 9000, 10000)

Flight tests, upgrades completed safely and securely

Tonopah Test Range successfully executed all assigned stockpile and developmental flight tests for the year, far exceeding the nominal test schedule. The tests were executed while Sandia integrated new sensor systems and data reduction software, and completed organic equipment upgrades to optical tracking systems, network and communication and radar systems. Test planning, execution and recovery processes and equipment were significantly adjusted to meet emerging requirements and mitigate associated hazards. All of the work was completed without a single safety or security incident. (2000)

Lab centers deliver 40,000 Components

The Sandia production community delivered more than 40,000 components in partnership with the Nuclear Security Enterprise and external suppliers in support of 51 products serving six different weapon systems. Nearly half of these components were new or modified designs. This outstanding effort maintained Sandia’s historically high product acceptance rate — a major accomplishment, especially considering the volume of work and the number of new products. (2000, 2500, 5000, 5200, 9000, 10000)

First production using model-based definition

Sandia is implementing model-based processes and tools on the W80-4 program to modernize and expedite Nuclear Deterrence product realization. Divisions 2000 and 8000 successfully developed the first ND component authorized for production using model-based definition. All product definition is derived directly from the native model, which includes 3D interactive viewable elements that allow direct model interrogation and replaces visual interpretation of 2D drawings, thereby improving quality, decreasing interpretation errors and resulting in overall cost and schedule savings for the Nuclear Security Enterprise. (2000, 8000, KCNSC, NNSA)

Mechanical shock test validates W88 ALT 370 effort

In August 2018, the Light Initiated High Explosive facility successfully simulated a hostile, cold X-ray encounter for the W88 ALT 370 qualification program. This full-reentry-body mechanical shock test provided model validation data and physical evidence for system qualification and also informed component-level mechanical requirements. The Sandia/New Mexico test was conducted in collaboration with Los Alamos National Laboratory, the National Nuclear Security Administration, Lockheed Martin Space Systems Company, Navy Strategic Systems Programs, Strategic Partnership Programs and Peraton Corp. (1000, 2000)

Model-based system engineering grows

Sandia created a new organization focused on model-based system engineering within the Nuclear Deterrence portfolio to transform how Sandia captures, traces and integrates system engineering objects such as requirements, tests, functions and components throughout the nuclear weapons lifecycle. MBSE, which uses models instead of long documents, provides information consistency to reduce nuclear weapon cycle time. Over the past five months, the MBS project portfolio has grown in applications within six different programs including the W80-4, Mk21 Fuze, and W76-2. (2000, 8000, 9000)

Demonstrator initiative aids stockpile modernization

The California Advanced and Exploratory Systems organization is participating in a continuous demonstrator initiative supported by NNSA and the U.S. Air Force, with potential benefits for future stockpile modernization programs. In FY18, the organization completed two subsystem tests, a mechanical system-level instrumented fit check of a Sandia-developed ground test unit, and Phase 3 of the Labs’ system- level functional demonstrator, providing systems context for both mechanical and electrical functionality. FY19 will add GTU environmental testing and aeroshell packaging of the functional demonstrator to further advance component and system-level technology. (8000)

Telemetry Transmitter team on time, on budget

The Legacy Joint-Test-Assembly (JTA) Telemetry Transmitter product realization team completed tester qualification at Kansas City National Security Campus and vendor sites, covering legacy transmitter families while meeting transmitter deliveries for all JTA telemetry next assemblies. The team worked with counterparts in the Nuclear Security Enterprise and with stockpile systems customers, identified solutions and implemented plans for quick resolution so transmitter deliveries could continue with minimal impact to assembly delivery schedules. The team developed an approach for delivering transmitters that met all requirements on time and on budget. (2200, 2600, 8200, 8400, 9400).

W88 hardware changes done with minimal impact

In February 2018, during radiation effects testing of the W88 ALT 370 Firing Subsystem, unexpected results occurred, driving significant risk into the remaining 14 months prior to component and systems level First Production Unit dates. The product realization team quickly assessed root cause and conducted initial prove-in of the design change. Simultaneously, the team expertly engaged with internal and external partners and stakeholders to expedite a new group build, alter hardware deliverables, codify testing activities and ultimately negotiate changes to schedule to minimize impacts. (2000)

NNSA touts W80-4 prep, reporting

The W80-4 program management team submitted its Weapon Design and Cost Report package to NNSA in FY18. Building upon resource-loaded schedules created earlier than for other modernization programs, the team conducted a formal Schedule and Cost, Risk and Uncertainty Analysis to estimate the program cost. They also delivered two other key reports in preparation for the expected transition to the next phase of the program. The NNSA federal program manager stated, “Our program has done more to get properly prepared for (this) Phase than any other LEP…” (8000)

Production soars at MESA

Microsystems Engineering, Sciences and Applications (MESA) processed 25 percent more wafer lot moves than anticipated at the beginning of FY18 while ramping down operations to enable the 6-inch to 8-inch tool conversion in the silicon fab. At the same time, the largest four-year Nuclear Deterrent wafer production run in MESA’s history was completed, a 79 percent increase from estimates made in 2014 due to increased customer demand. Wafer deliveries were completed for all current weapon programs, critical sensor programs, pre-builds for future systems and development lots for scores of R&D projects. (5000)

W80 ALT 369 goes to full-scale production

The W80-1 ALT 369 project successfully transitioned to full-scale production in FY18, meeting the NNSA production and delivery schedule. Close partnering between Pantex and Sandia during initial builds ensured a smooth production ramp-up. Neutron generator, detonator and gas transfer system components groups provided rapid resolution of production issues. Kansas City National Security Campus implemented a substantially expanded re-acceptance testing program on a major component to detect and screen potential temperature dependencies. The W80 ALT 369 replaces several limited-life components in the warhead, ensuring effective deterrence into the future. (2000, 8000, 9000)

SP115 Acorn reservoir qualified in Kansas City

In support of the W87 ALT 360 Program, the Sandia/California Gas Transfer Systems product realization team successfully qualified the SP115 Acorn reservoir at Kansas City National Security Campus. The work was accomplished in partnership with the W87 systems team, Kansas City and Savannah River Site. The first production units were delivered to SRS, supporting final MC4957 reservoir qualification in support of the Acorn GTS delivery to the U.S. Air Force in January 2019. This innovative system is designed to extend its life and improve the quality of gas delivered. (8000)

First custom radar circuits qualified

Sandia’s first custom-designed Radio Frequency Integrated Circuits have been qualified for use in joint radar modules, supporting three nuclear weapons programs. These RFICs were designed in five different foundries offering bulk acoustic wave, gallium arsenide, gallium nitride and complementary metal oxide semiconductor technologies. Eight years of significant design and characterization effort culminated in the qualification of 16 different designs, and more than 100,000 RFICs during FY18. (5000)

W80-4 program delivers test assets to U.S. Air Force

The W80-4 Life Extension Program delivered multiple test assets to the U.S. Air Force, including Fit Check Unit types 1 and 2 and Warhead Communication Simulator 1. The team also completed assembly and early testing of a highly instrumented ground test unit. On-time delivery and testing of these assets are critical to mitigate early program risk and forge strong relationships between NNSA and the U.S. Air Force. A key technical achievement for the W80-4 Life Extension Program, the test assets help ensure success of the W80-4 warhead and missile weapon system. (1000, 5000, 8000)