Today, complex environmental testing requires upfront modeling, advanced instrumentation measurement, and significant post-test analysis. We realize our customers can leave a test with terabytes of data. But data is not information. To help our customers get the most value out of tests, we provide analytics that aggregate test data into meaningful information, and then fuse all the information together with the right imagery to bring it to life. This often leads to new discoveries about the test dynamics and anomalies – information not captured in models. Our customers also find that these high-level data fusion products become critical tools to communicate the success of their work to funding agencies.

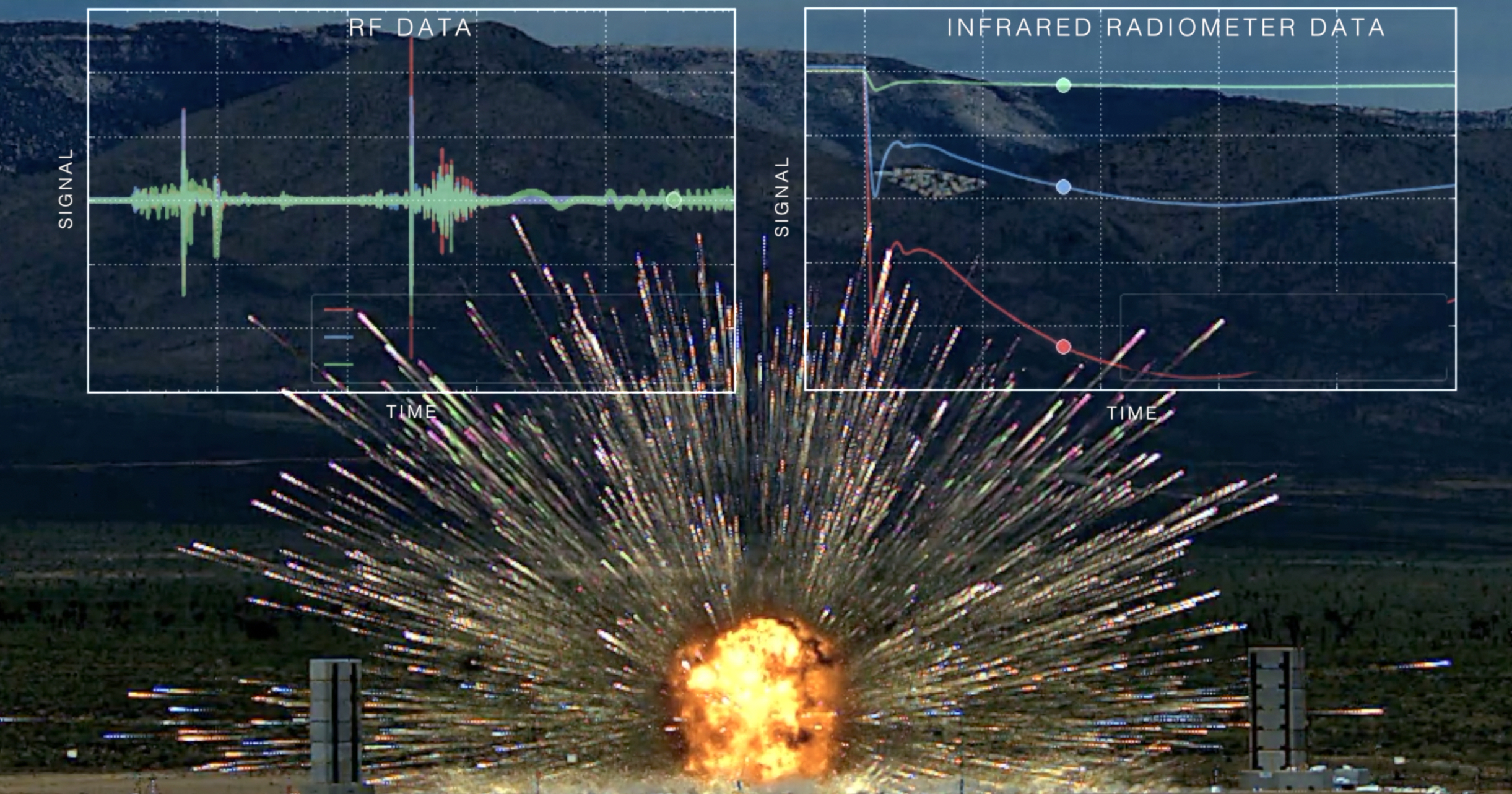

Fusion of Instrumentation Data

By merging instrumentation data with high-speed imaging, complex event dynamics can easily be visualized. Understanding when voltages drop in relation to the mechanical dynamics is easy with the standard compliant data fusion product we produce. If you can record it, we can fuse it. Our team works in the planning stages to ensure that all the critical timing fiducials are in place so that all test data can be synchronized and visualized as a single product.

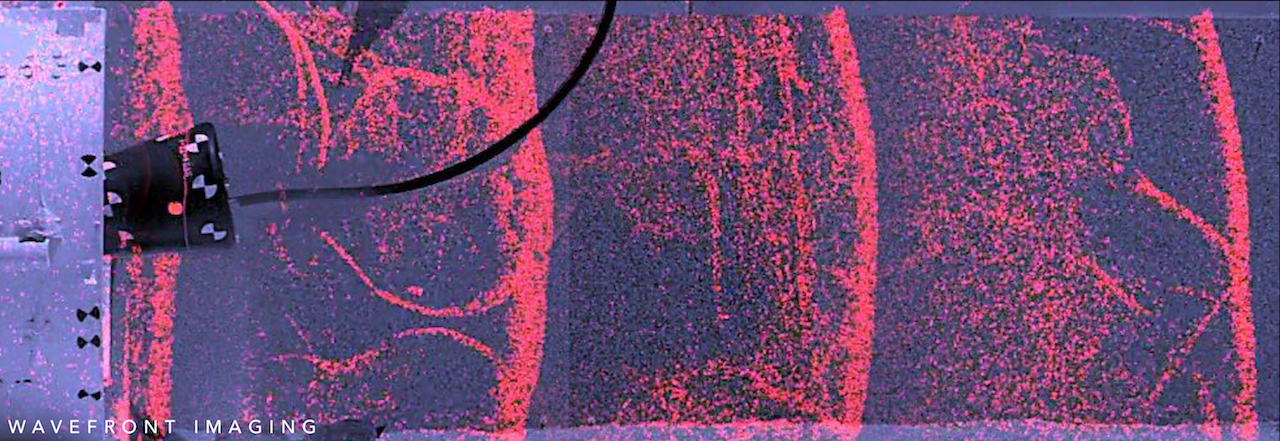

Fusion of Imaging Data

Measuring data from imagery is not enough. To fully understand the data, it is critical to visualize it. We have unique in-house tools that allow us to generate informative and appealing visualizations of the non-contact imaging measurements. By retrojecting 3D measurement data back onto 2D camera views, subtleties like unit cracking can be understood in the context of the overall motion dynamics and impact sequence.

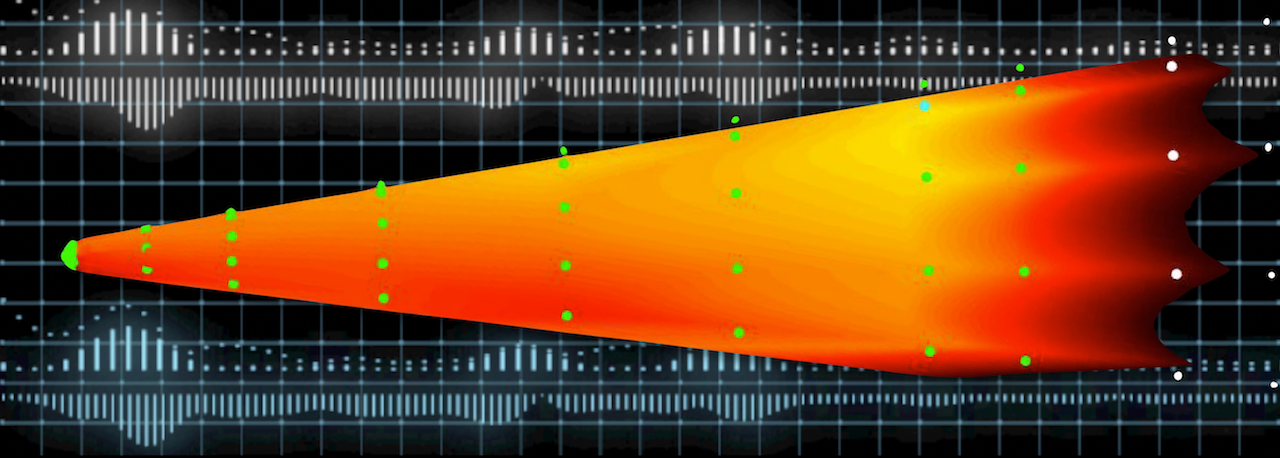

Fusion of Model Data

Today, Sandia National Laboratories is at the forefront of integrated engineering, modeling and testing. We use a closed-loop cycle where the engineering informs models, models inform tests, and the tests feed back into the models and engineering designs. A key part of this process is visualizing 2D and 3D models (mechanical, thermal, electrical, etc.) re-projected onto calibrated 2D & 3D imagery. With the model fused with the imaging measurement, instrumentation data, and high-speed imaging, the test team can fully understand the outcome of a test and inform the next step of an integrated engineering process.

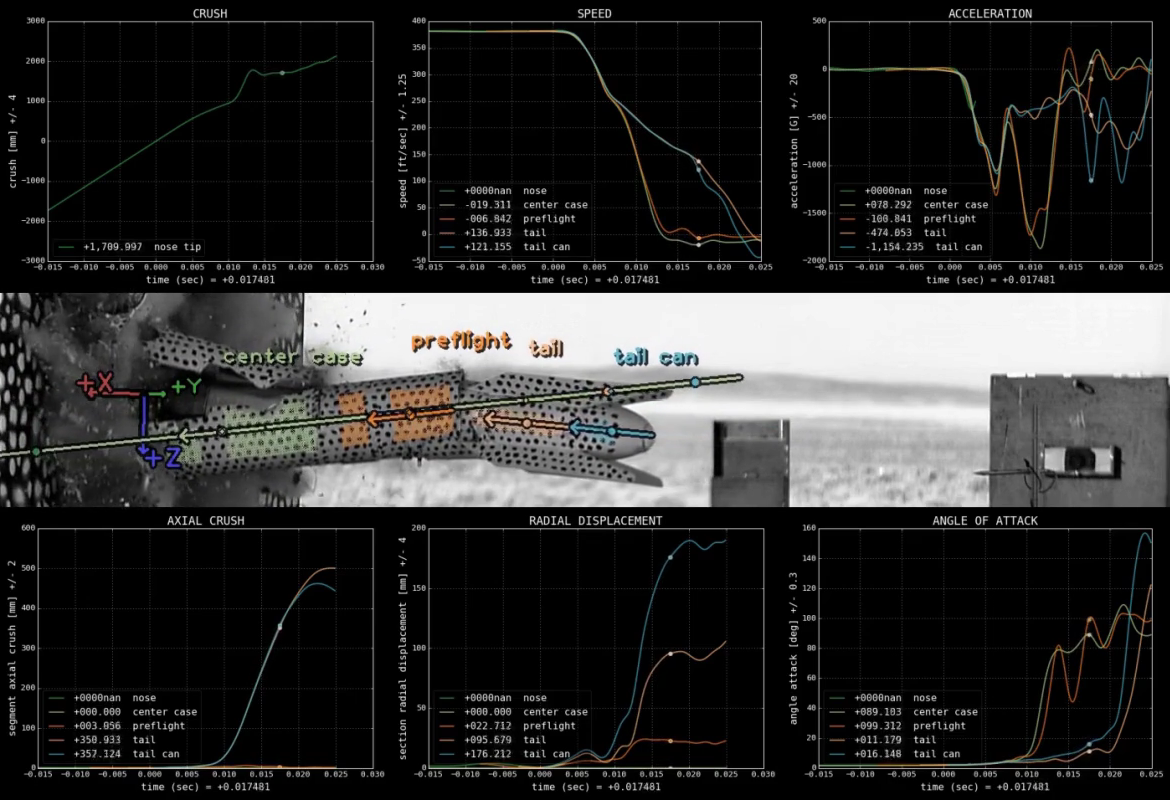

Advanced Data Analytics

Because data is not information, our team doesn’t stop working after we have collected test data. A point cloud of 3D imaging data moving through space and time is not easy to work with, and doesn’t provide much insight into a test’s dynamics. We work with our customers to understand the key metrics that will answer their questions. Then we design imaging measurements that can harvest the data, which is then fed into advanced analytical tools we have developed; this aggregates data into something useful for our customers.