Sandia partnerships, technologies win four regional tech transfer awards

A New Mexico company secured funding this year and located 240 acres of land in the southeastern corner of the state to build a small reactor that exclusively will produce medical isotopes. The concept was developed and licensed by Sandia to help establish a stable domestic supply of medical isotopes, which are made with low-enriched uranium and are used to help diagnose a number of diseases.

Adjustments to the license made by Sandia earlier this year helped Eden Radioisotopes LLC secure funding. Eden’s chief operations officer Chris Wagner said he expects to break ground on the facility once all other licensing and agreements have been reached.

This effort earned a regional Excellence in Technology Transfer Award from the Federal Laboratory Consortium, which recognizes federal laboratories and their partners for outstanding work to develop and commercialize innovative technologies.

Medical isotopes used in 40 million procedures each year

Medical isotopes are used around the globe in imaging procedures that diagnose heart disease, cancer and other life-threatening conditions. The isotopes are injected into patients and emit gamma rays that can be tracked in the body, letting physicians create images of the spread of a disease. They also decay quickly so patients are exposed to little radiation.

Building the reactor is important because there are a limited number in the world that primarily produce molybdenum-99, or moly-99, which decays to technetium-99m, a short-lived isotope that can be used to make individual patient doses, said Wagner. Some of those reactors have unplanned outages, causing shortages and price spikes.

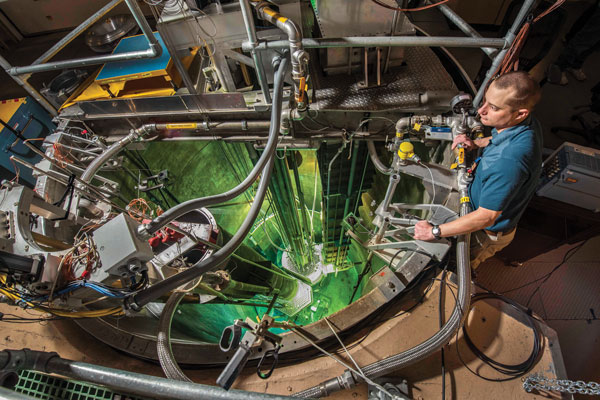

Sandia’s concept is to produce moly-99 with a small, 2-megawatt reactor, which would require less maintenance than larger reactors. The technology, which uses low-enriched uranium, could help produce a reliable domestic supply of moly-99 without the use of highly-enriched uranium. Eden was able to demonstrate that they had a funding plan and enough experience to obtain an exclusive license for the technology.

“This has been a stellar example of transferring Sandia technology,” said Sandia business development specialist Bob Westervelt, who worked on licensing the concept. “The team that worked on this from Sandia was really committed to making this work, and Eden is making it possible for the technology to move forward. Everyone involved put in a lot of effort over many years to make this a success.”

The isotope is used for 40 million nuclear medicine diagnostic procedures each year, Wagner said. In the U.S. alone, the isotope is used for more than 40,000 medical diagnostic procedures each day, according to Sandia senior manager Matt Burger.

The purpose for producing the isotopes and the dedication to this issue are deeper than science and solving a problem, Wagner said.

“This type of technology has the ability to affect millions of patients worldwide,” he said. “I think what continuously drives us is that unless someone solves the supply issue, a lot of patients will be adversely impacted. At the end of the day, a lot of people will benefit, but they won’t know our names. It’s that internal satisfaction of making a difference that drives us.”

A catalyst, an alloy and a zero-emissions research vessel

In addition to this effort with Eden, the Federal Laboratory Consortium recognized three other projects involving Sandia in the Mid-Continent and Far West regions.

- One partnership earned a Notable Technology Development Award for a breakthrough in using detergent to make uniform powder catalysts that outperform commercial varieties used to kick-start chemical reactions. The catalytic compounds could be used in many applications, including environmental clean-up and cancer treatment.

- Labs’ researchers earned a Notable Technology Development Award for engineering the world’s most wear-resistant alloy, which has gained tech transfer interest from companies in several sectors. The alloy is 100 times more durable than high-strength steel and could make electronics of all sizes and across many industries more cost-effective, long-lasting and dependable.

- Sandia received an Outstanding Partnership Award for research on a zero-emissions research vessel. A Sandia report showed it is technically and economically feasible to build a vessel that meets marine regulations and doesn’t pollute the air or ocean.

“We are proud to celebrate and recognize our industry partnerships, technology and technology transfer efforts that support Sandia’s missions,” said Jackie Kerby Moore, Sandia’s technology and economic development manager and the Labs’ Federal Laboratory Consortium representative. “These technologies are being developed and transferred to the private sector and will create many business opportunities.”

Sandia winners were recognized at a recent awards ceremony at the FLC Far West/Mid-Continent Regional Meeting in Livermore, California.