20″ Actuator – Impact Testing

20″ Actuator – Shock Test High Speed

6″ Gas Gun – High Velocity

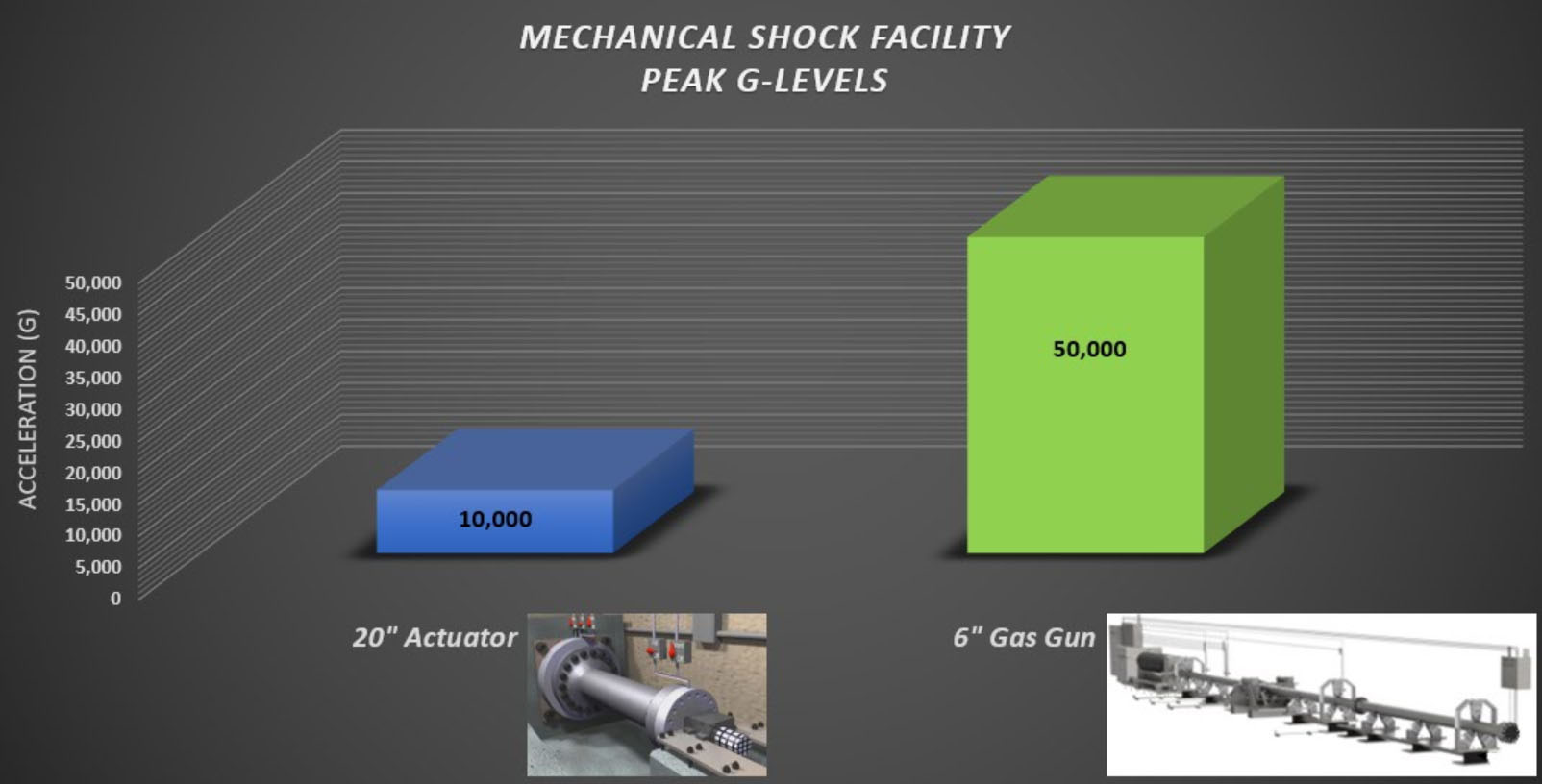

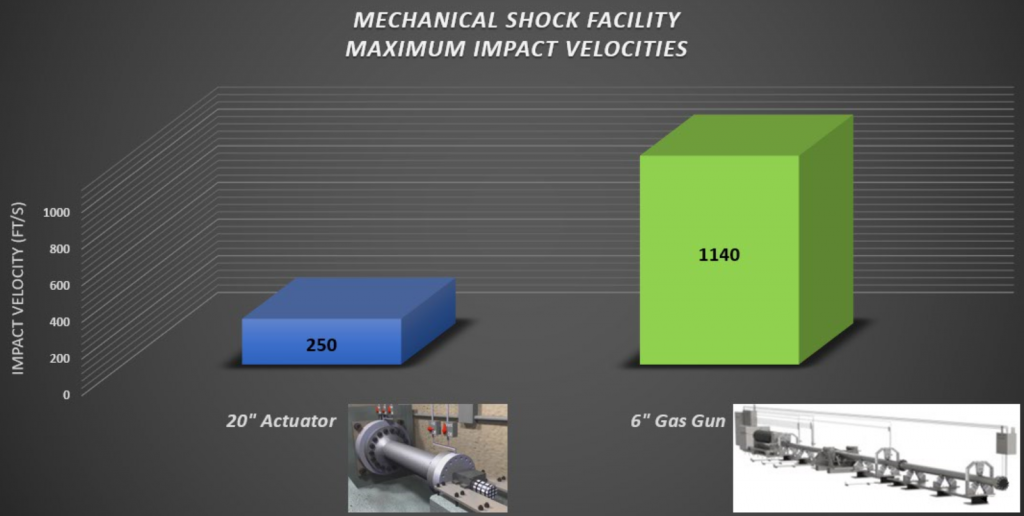

Our primary tools are a pneumatic actuator-and-sled system and a 6-inch bore gas gun. We can test articles up to 10,000 lbs. Depending on the size and weight of the test article, we can apply velocity changes up to 1,140 ft/s, and attain acceleration levels on the order of 50,000 g.

Click here to view the virtual tour

We are an indoor facility that is temperature-controlled and shielded from weather. We can measure unit function, test article kinematics, and material deformation. Our measurement tools range from accelerometers and strain gages to advanced photometrics and high-speed radiography.

Feel free to contact us to discuss the feasibility and details of meeting your impact testing needs.

*Levels in the graphs above will decrease, based on complexity, unit weight, and other variables.

- The 20” Actuator is better suited for larger, heavier test articles

- The 6” Gas Gun is better for smaller test articles and/or high-impact velocities

- Both systems excel in the following fields:

- Component-level to system-level test articles

- Hazardous and/or classified test articles

- Shock, crush, pyroshock, and other impact simulation

- Contact us with specific test requirements for more information

Downloadable Poster