Sandia engineer helps design a way to expose suicide bombers before they walk into a crowd

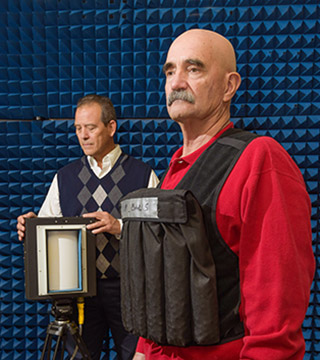

Wearing a mock suicide vest, Albuquerque businessman Robby Roberson stands in front of his company’s CBD-1000 bomb detector, being adjusted by Sandia scientist JR Russell. JR worked with R3 Technologies to iron out technical issues and bring the suicide bomb detector close to commercialization. (Photo by Randy Montoya.)

On the chilling list of terrorist tactics, suicide bombing is at the top. Between 1981 and the end of 2015, an estimated 5,000 such attacks occurred in more than 40 countries, killing about 50,000 people. The global rate grew from three a year in the 1980s to one a month in the 1990s to one a week from 2001 to 2003 to one a day from 2003 to 2015.

Terrorism experts say suicide bombings are pervasive because they generate publicity and require little expertise, resources, or planning. They instill fear and breed distrust in the public, a goal of groups determined to spread terror. Perhaps most importantly, suicide bombings are almost impossible to prevent.

“The suicide bomber can walk into a crowded place unnoticed and inflict a horrifying amount of death and destruction,” says Albuquerque businessman Robby Roberson. “It’s very hard to stop. There’s no technology to deal with it.”

Until now, Roberson says. His company, R3 Technologies, is working with a group of small businesses to develop a way to prevent suicide attacks by detecting concealed bombs before they go off. After a frustrating start, the group decided it needed more technical help and turned to the New Mexico Small Business Assistance (NMSBA) program, which pairs entrepreneurs with scientists and engineers at Sandia and Los Alamos national laboratories.

Turning things around

R3 found a partner in Sandia sensor expert JR Russell who, during the past two years, has helped bring the company’s Concealed Bomb Detector, or CBD-1000, close to commercialization.

“JR has been all over it and really turned things around for our company,” Roberson says. “He is terrific. He brings in sharp people from Sandia. I love working with those guys.”

JR, a 35-year veteran of the Labs, says his role largely has been to develop metrics to quantify the performance of the technology. He zeroed in on the device’s accuracy by analyzing false positives and pushed to redevelop software so it would more reliably detect a bomb threat. “After getting to know Robby and the team I got more and more interested in the problem,” says JR, who enlisted a couple other Sandia engineers, Matt Erdman and Michael Bratton, in the project. “The technical part of me took over. Engineers want to validate the model and we needed to validate the performance of Robby’s system. We threw out a lot of the existing technology and made proposals to Robby, and they went with it. Early versions were a good start, but not where the technology needed to be.”

Screening in public places

The CBD-1000 uses X-band radar to detect metallic and non-metallic explosives. Roberson says it can detect ball bearings, glass, nails, ceramics, rocks, and other materials frequently used as shrapnel in suicide vests.

The device is designed to detect bombs that current metal detector technology would miss and is intended for screening areas such as airports, embassies, public and government buildings, border crossings, transportation hubs, and military compounds. It is portable and could also be used at special events where crowds are expected.

The CBD-1000 is the size of a cereal box, weighs about 13 pounds, and is mounted on a tripod. It is powered by AC or battery and works with proprietary embedded software. “The device uses a spread spectrum, stepped, continuous wave radar to bounce a signal off a subject. The software analyzes both horizontal and vertical polarized signals to determine the presence of a potential threat. If the person is not carrying a threat, the return signal is in the same polarity as when it was transmitted,” Roberson says. “A threat will rotate the polarity of the signal, and it comes back differently.”

The system sets up in about 15 minutes and an operator, who does not need a working knowledge of radar, can be trained in 30 minutes. The scan takes about 1.3 seconds at 9 feet.

“We’re working toward an instantaneous scan so a person can be checked while moving through the beam field. And we hope to extend the range to 100 feet,” Roberson says. “We want to take movement out of the equation. People who want to protect their citizens want to detect at a distance, keep the threat away. They want to scan crowds and stop threats before they get too close.”

Roberson says algorithms are being finalized that will allow scanning at greater distances while people are moving.

System reached a plateau

The original technology was developed by the Albuquerque company Safe Zone Systems in the early 2000s as a hand-held, radar-based sensor that police could use to scan people moving at a distance who they suspected might be armed. It evolved into a stationary system. “It was after 9/11 and there was a thought that we could change our approach and see if we could detect suicide bombers,” Roberson says.

After years of development, the technology just didn’t work. “It became apparent that the system was not completely accurate,” Roberson says. “It reached a plateau. We could not get it to get better. The hope was always to improve the accuracy.”

Roberson’s father, homebuilder Coda Roberson, was a shareholder in Safe Zone, and Robby joined the company in 2009. The father and son founded R3 Technologies to further develop and commercialize the technology.

They approached Sandia for help through NMSBA and added partners including Manuel Rangel of APPI Inc. in Las Cruces, the acclaimed radar scientist Don McLemore of McLemore Enterprises LLC in Albuquerque, Lawrence Sher of Wind Mountain Research Associates in Albuquerque, and Julie Seton of Indelible Enterprises in Las Cruces.

“When JR came onboard we all took a hard look at what we had, what it did, and how it worked,” Roberson says. “JR came at this problem from a different point of view. He wanted to know everything about it. He helped us realize we had to go in a completely different direction. We reverse engineered the hardware and software. I can’t stress enough how important JR was. He helped with everything.”

JR says the Sandians studied noise surrounding the radar signal and how it impacted true positives and true negatives. They found a way to reduce noise and strengthen the signal, improving accuracy. “If the signal is bigger than the noise, it can scan people as they’re walking. They don’t have to stop,” he says. “These breakthroughs will enable new applications in security of the future and will increase the marketability and desirability in the field of the CBD-1000.”

Starting a third NMSBA project

Roberson says the CBD-1000 will cost about $50,000 and that several hundred units have been produced. The device is patented, and the company has received inquiries from Pakistan, Afghanistan, Singapore, Kuwait, Saudi Arabia, and Nigeria, he says.

Roberson hopes to go to market this year. His business group has worked with JR under two NMSBA projects over three years and started a third in January to finalize the product by further improving speed, distance, and accuracy. The group meets weekly. “We all clicked as people,” JR says. “We have a common focus and all march in that direction. Everybody brings their technical expertise. These are energized people who are the poster child for a highly effective team. It doesn’t feel like work to me. I’m lucky to work with them.”

JR says he enjoys helping a small business. “It’s good for our community,” he says. “Helping someone succeed helps us succeed, too, as a lab. I get to see science though the eyes of business people. And I’ve learned things that will help me in my work.”

JR says R3’s suicide-bomb detector resonates with Sandia’s national security mission. “We want to help our nation protect our people, our assets,” he says. “If we can save one life, we can make a difference. The opportunity to make us safer from attacks is one of the idealistic things that drive us.”

A vital tech transfer tool

The New Mexico Small Business Assistance (NMSBA) program was created in 2000 by the state legislature to bring national laboratory technology and expertise to small businesses in New Mexico, promoting economic development with an emphasis on rural areas.

The program has provided more than 2,300 small businesses in all 33 New Mexico counties with $43.7 million worth of research hours and materials. It has helped create and retain 4,086 New Mexico jobs at an average salary of $38,488, increase small companies’ revenues by $200 million, and decrease their operating costs by $85 million. These companies have invested $68.3 million in other New Mexico goods and services and received $77.1 million in new funding and financing.

R3 Technologies was among 364 small businesses in 24 counties that participated during 2015 in NMSBA. In addition to Sandia and Los Alamos, the program contracts with the New Mexico Manufacturing Extension Partnership, University of New Mexico Management of Technology program at the Anderson School of Management, UNM School of Engineering, Arrowhead Center at New Mexico State University, and the New Mexico Tech Department of Management. NMSBA provided $4.7 million worth of assistance to New Mexico small businesses last year.“The project between Sandia and R3 Technologies is a compelling example of how NMSBA is not only helping a New Mexico small business but also helping Sandia’s national security mission,” says Jackie Kerby Moore, manager of Technology and Economic Development Dept. 1933. “Kudos to JR and his team for helping the company commercialize their technology.”