Who We Are

Sandia National Laboratories’ Metal Micromachining Program specializes in the fabrication of small innovative devices. Through a consolidated, in-house capability, unique products are created using advanced, nontraditional processing of exotic and diverse materials. With expertise in the fabrication of thick, high aspect ratio uniform metal and metal alloy structures too small for traditional machining, the Program maintains a suite of tools and capabilities that transform big ideas into little devices.

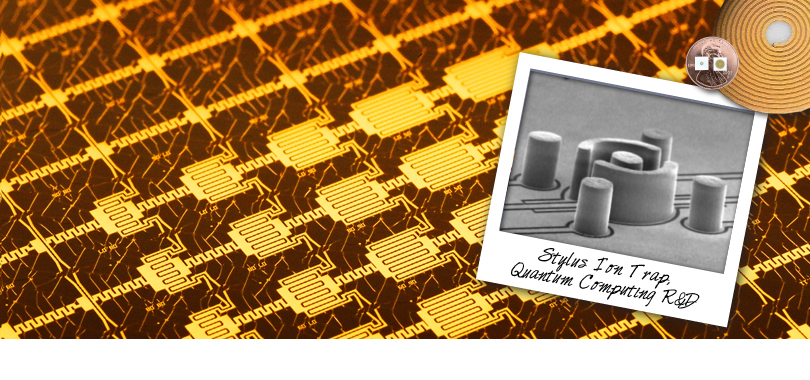

The Metal Micromachining Program leverages three core capabilities— fundamental science, process development, and product realization— to produce devices without the inherent limitations that exist in other approaches. Its technologies have been applied to diverse fields including quantum computing, photovoltaics, kilohertz waveguide development, nuclear magnetic resonance imaging, and phase contrast imaging. Exceeding beyond simple chemistry and molding, the Metal Micromachining Program employs an exacted flow dynamics process to fabricate devices with the highest degrees of accuracy and precision to ultimately meet a broad range of national security needs.

Core Capabilites

Micromachining research, development, and fabrication of this nature require a well-developed suite of core enabling capabilities. The Metal Micromachining Program offers a unique environment which combines expertise, facilities, and equipment necessary to dynamically build upon the area both through theory-based exploration and fabrication of functional devices.

Electrochemical research and development (R&D) and engineering serves as a theoretical and practical basis for the Metal Micromachining Program.

The Metal Micromachining Program maintains three fabrication labs dedicated to process development, which makes it capable of performing full-spectrum fabrication.

The Metal Micromachining Program produces functional coatings and high aspect ratio 2.5D electroformed structures too small for traditional machining to help customers develop, design, and fabricate products never-before thought possible.

THINK LITTLE, DREAM BIG: Sandia’s Metal Micromachining Program

Sandia National Laboratories’ Metal Micromachining Program specializes in the fabrication of small innovative devices. Its technologies have been applied to diverse fields including quantum computing, photovoltaics, kilohertz waveguide development, nuclear magnetic resonance imaging, and phase contrast imaging.

With expertise in the fabrication of thick, high aspect ratio uniform metal and metal alloy structures too small for traditional machining, the Program maintains a suite of tools and capabilities that transform big ideas into little devices.

Process

Fabrication begins with the creation of a precise, photoresistant mold on top of a metalized surface, otherwise known as lithography. Using a variety of advanced techniques including UV exposure, device characteristics are transferred to the mold in a way similar to how pictures are produced from film negatives.

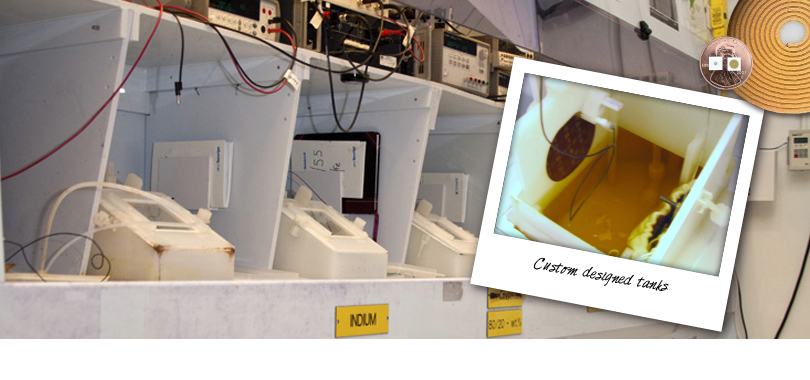

Once the mold is created, it is placed in an electroplating bath containing a metal dissolved in uniform solution. The bath, designed for high aspect ratio electrofilling of molds, propels jets of solution across the mold to create a solid, uniform accumulation of metal. However, deviating from other techniques, the Metal Micromachining Program engages in a bottom-up electroplating process, rather than top-down.

When required, electrochemical cells with rotating disc electrodes and potentiostats are used to perform a variety of experiments. In the controlled environment, proof of concept, process development, and small-scale deliveries can be achieved.

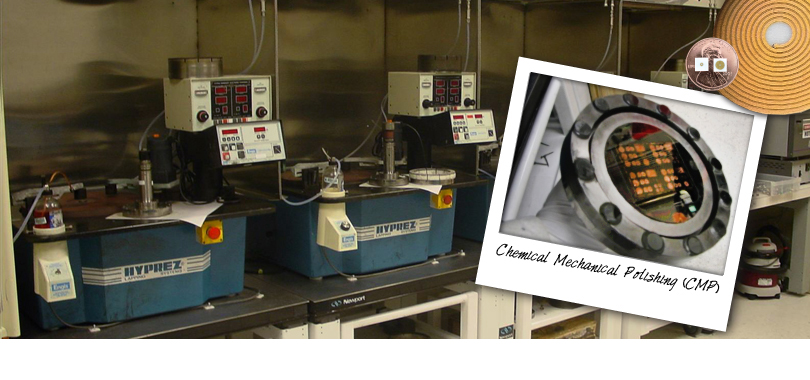

Finally, if needed, the device can be lapped down to planarize the plated metal and the top of the resist mold. The metal is placed on a polishing wheel where it is buffed and polished to ideal quality, often for mechanical or optical purposes. Once the planarization is completed, the newly created metal device is ready for use.

Lab Features

The Lithography Laboratory is equipped with its own Class 100 clean room, a collection of spinners and exposure stations, as well as an ultrasonic agitator and a megasonic agitator.

The Electroplating & Characterization Laboratory features a variety of function generators, in addition to a Profileometer, X-ray fluorescence (XRF) spectrometer, Nanco Spec, and diffusion bonder.

The Planarization Laboratory houses an assortment of polishing wheels varying in metallic coating and subsequent degree of hardness, along with an array of polishing slurries featuring diamond bits ranging down to 1/10 of a micron.

Summary

The Metal Micromachining Program leverages the electrochemical fabrication process to produce its devices without the inherent limitations that exist in other approaches. Through a consolidated, in-house capability, unique products are created using advanced, nontraditional processing of exotic and diverse materials.

Media

Fact Sheet

Download PDF (75KB)

Stylus Ion Trap Animation

Play Now