FIREBALL — A W87-1 test conducted at the 120’ blast tube as captured by Sandia Photometrics. High-speed video shows explosive testing, subjecting the test article to the resulting shock wave. (Video by Sandia Photometrics)

Creating and modernizing the nation’s nuclear deterrence capabilities require the collaboration of innovative teams across the Labs. One division heavily integrated in these efforts is Advanced Science and Technology.

“With a strong partnership between AS&T and our mission partners, we are rapidly innovating, advancing and integrating our capabilities and technologies to meet the nation’s future mission needs,” Experimental Mechanics and Dynamics Senior Manager Steven Samuels said.

The division comprises six centers, in which scientists conduct cutting-edge research in materials science, explore new advanced computing and sensor technologies, and employ sophisticated modeling and simulation techniques to predict the performance of weapons. Experts use machine learning and artificial intelligence to inform critical design decisions, and engineers bring the systems full circle by conducting laboratory testing and field trials to help predict system performance.

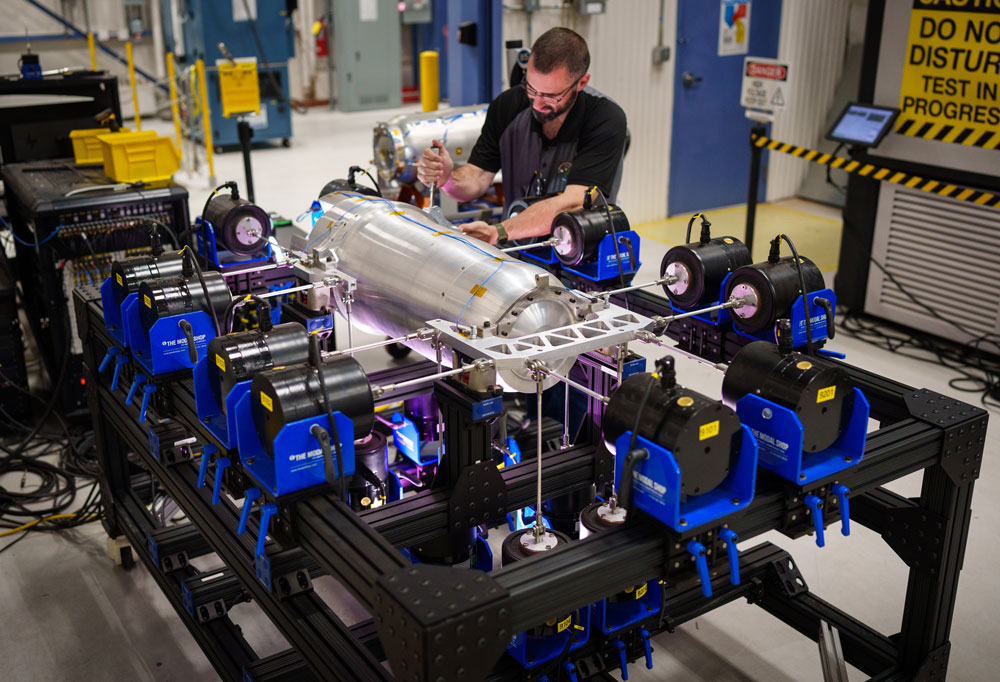

Advanced Science and Technology develops broad capabilities needed by weapons systems, such as the W80-4, the W87-1 and the W93. For example, each system component must be exposed to complex stress states, so the Experimental Solid Mechanics team uses a planar biaxial load frame to simulate real-world conditions and apply torsion to see how materials behave.

The Energetic Environments team also performs testing for extreme conditions, including a new method for conducting explosive flyer plate tests. Rather than conducting one full-scale test, the team developed eight scaled tests with a variety of variable changes. This allows the team to collect data that informs development techniques for full reentry bodies and reentry vehicles at previously unattainable ground test speeds, saves costs and increases the speed of setup.

The same team also developed a device to calibrate the sensors that measure linear displacement, or position, with a high degree of accuracy. This new system saves hundreds of hours each year while providing higher confidence in the testing and evaluation of various components and systems associated with nuclear warheads and delivery systems.

Integrating advanced technology for the W80-4 Life Extension Program

The W80-4 Life Extension Program was developed to ensure the effectiveness of the bomber leg of the nuclear triad when coupled with the Air Force’s Long Range Standoff Cruise Missile. To meet the needs of the Life Extension Program, teams across Sandia are partnering to integrate advanced technology from Advanced Science and Technology within existing systems.

Rapid modeling and simulation techniques have been applied by the Engineering Sciences center to inform design decisions for the W80-4 Life Extension Program warhead case, ensuring the case can withstand challenging environments. The teams also evaluated the “simplification” redesign effort of the W80-4 case by deploying advanced ultrasound and radiography techniques.

With new multiple input and multiple output methods, Sandia is now able to “fly on the ground,” by replicating vibration environments with high fidelity. This resulted in test schedules reduced by up to one-half depending on configurations and environments, and programmatic cost savings as well. The W80-4 program reduced their test schedule by 12 weeks, resulting in time and budget savings on one test series alone.

Karen Rogers, senior manager for the Validation and Qualification Sciences group, said, “The insights we are gaining for the mission are invaluable, as they enable us to anticipate the stresses our weapons will endure and provide accurate test data to our modeling teams.”

Revitalizing the W87-1

The W87-1 is a new design based on previously fielded concepts with improved safety and security features.

“Finding innovative ways to meet the country’s national security needs is why Sandia exists,” Material, Physical and Chemical Sciences Center Director Joel Lash said. “There is so much ingenuity among our scientists and engineers. I’ve never seen a problem they can’t solve or a process they can’t improve.”

One problem the Impact Environments team faced was how to create complex components while reducing waste for the Characterization Mechanical, or CHARM, drop tests, which were used to begin activities for a nuclear safety assessment of the W87-1 in abnormal mechanical environments.

The teams reviewed the test parameters for the W87-1 and developed 3D-printed sacrificial fixturing that could fully guide the unit to impact, reducing unwanted effects during free-flight from environmental conditions, such as wind. Traditional manufacturing would have taken weeks. 3D printing took a day, including updates, fabrication and application.

Scientists and engineers in the Material, Physical and Chemical Sciences organization have established new methods to create parts to assist with material accessibility within the supply chain. They developed a new process to weld copper with a blue laser welder that enabled the W87-1 team to make cables meeting new mission critical environment requirements. They also introduced two new nuclear security enterprise-controlled formulations for fluorocarbon O-rings, which are crucial to maintaining system environment controls. Controlling the formulations makes the nuclear security enterprise more robust to changes in material availability and vendor dynamics.

Informing design decisions for the W93

The W93 warhead, a new contribution to nuclear deterrence, aims to decrease reliance on the W76 system and will allow the U.S. to keep pace with the future adversarial threat.

“When we look for credible solutions to help safeguard our country, I know that engineers and researchers at the Labs will be part of the solution. That includes the design, analysis and testing for the new W93,” Sandia’s Engineering Sciences Center Director Basil Hassan said.

For the W93, one innovation includes a quick-turn feasibility matrix allowing designers to conduct informed trades between environmental flexibility and risk, manufacturability and component reuse. Advanced Simulation and Computing-developed software is providing confidence that the updated design will significantly reduce the likelihood and susceptibility of the warhead to lose positioning in abnormal electrical environments.

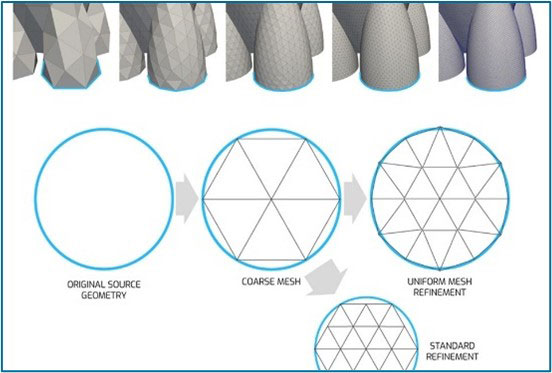

Cubit, a mesh generation toolkit for solid models developed by the Engineering Sciences center, is enabling certain radiation-simulation tasks for parts to be accomplished in one day as opposed to weeks. Cubit can instantly perform calculations related to shape dimensions, significantly reducing the time needed to generate 3D overlays needed for studying thermomechanical shock and thermostructural response.

By leaning into intelligent risks, collaborating and maintaining a steadfast commitment to excellence, Advanced Science and Technology is strengthening national security, improving modern weapon systems and ensuring they remain relevant for decades to come.