Sandia researchers are developing clean and renewable sources of energy to help minimize climate change and reduce U.S. dependence on fossil fuel oil. To this end, we are creating thermochemical, chemical, and biochemical conversion technologies to efficiently generate renewable biofuels that can displace gasoline, diesel, and jet fuel with no loss of performance or engine efficiency. Sandia is focused on two primary feedstock types—lignocellulose and microalgae—that show great promise for displacing fossil fuels, once significant R&D challenges are overcome.

Algal Biofuels: Advancing This High-Potential Fuel Toward Commercialization

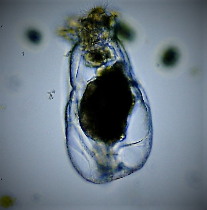

Biofuels derived from microalgae at the commercial scale could, if efficiently produced, meet the transportation fuel needs of the United States—while using a much smaller land area compared to that required by other non-food plant fuel sources. Sandia’s broad research program addresses a wide range of challenges including improved growth yield, resiliency, and resistance to predation.

Microalgae are an ideal feedstock for a number of reasons including the ability to use CO2 as a nutrient and the ability to grow in brackish water and on land not suitable for food production. They have the potential to produce much higher fuel yields than other land-based biomass feedstocks. Recognizing the need for significant breakthroughs to advance this beneficial fuel source to commercial viability, Sandia is pursuing R&D on several fronts:

- Increasing the productivity and stability of algal ponds through polyculture

- Creating advanced dewatering techniques for separating algae from growth culture

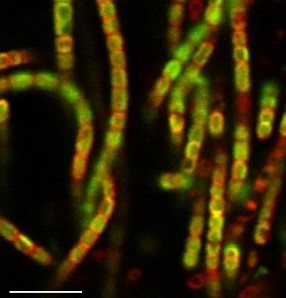

- Developing advanced spectroscopic and microfluidic field diagnostic tools to monitor microalgae health and production of lipids—the main source of fuel energy— pondside

- Designing and implementing computational modeling of algal cultivation ponds, also called raceways

- Conducting lifecycle and systems analysis of algal biorefineries

- Identifying strains that have higher yield or increased resistance to predation

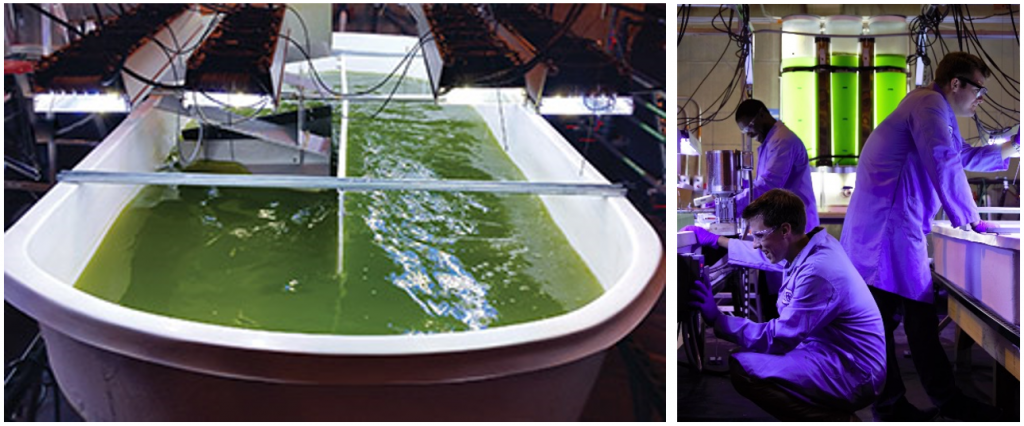

Algae Raceway Testbed

Sandia has established an algae raceway testbed in the Livermore Valley Open Campus—a new collaboration space hosted by Sandia and Lawrence Livermore National Laboratory—to test new technology and overcome challenges facing algae biofuels. This growth facility is an important intermediate step in the ultimate scale-up from the laboratory bench to the production scale outdoor. It enables rigorous testing of advances in microalgae in settings that more closely approximate the real world.

Lignocellulosic Niofuels: Enhancing the Promise by Reducing the Costs

Abundantly available from sustainable non-food U.S. sources, lignocellulosic biomass is seen as a critical feedstock for the production of renewable fuels and bio-derived products. Though major progress has been made, significant reductions in energy inputs and productions costs are still needed before lignocellulosic biofuels can become truly cost-competitive. Sandia has a vibrant research program focused on a wide range of topics including breakdown of plant matter to access celluloses and sugars and the conversion of lignin —a significant component of most plant-based biomass— to commodity chemicals in a process known as valorization.

Sandia works in a variety of areas to create advanced conversion technologies for generating high-performance biofuels. These include:

- Building a fundamental understanding of biomass conversion through advanced imaging and spectroscopy

- Developing advanced biomass pretreatments to enable more efficient liberation of sugar from a wide range of feedstocks

- Engineering lignocellulolytic enzymes that can survive in higher temperature and higher salinity environments

- Developing routes to creating valuable products from lignin, a major byproduct of biofuel generation

- Pursuing synthetic biology approaches to enable organisms to generate higher biofuels production levels

- Conducting lifecycle analysis and techno-economic modeling of biorefineries

Joint BioEnergy Institute (JBEI)

As a key partner in the Joint BioEnergy Institute (JBEI), SNL discovers, optimizes, and improves the process economics of ionic liquid biomass pretreatment systems; discovers, optimizes and improves the process economics of microbial and enzyme biomass pretreatment and lignocellulose–to–chemicals–and–fuels conversion systems; uses genetic engineering and bioinformatics tools to increase the efficacy of fungal biomass pretreatment biotechnology; and develops microfluidic and high–throughput biochemical tools for screening ionic liquid and synthetic biology applications.

The Department of Energy’s Joint BioEnergy Institute (JBEI), led by Lawrence Berkeley National Laboratory (Berkeley Lab), was selected in July 2017 as one of four DOE Bioenergy Research Centers to be awarded a total of $40 million to support innovative research on biofuels and bioproducts. JBEI has five national laboratory partners and six academic research partners.

The BRC awards, announced by Secretary of Energy Rick Perry, mark the next research phase at JBEI, established in 2007 by the Office of Biological and Environmental Research within DOE’s Office of Science. JBEI and the new centers will expand their focus on breakthrough science in carbon-neutral biofuels to include more research into the development of innovative bioproducts and bio-based chemicals.

Examples of Recent Research

Co-Optimization of Biofuels and Engines

As a key partner in the Co–Optima project, SNL aims to optimize transportation fuels and vehicles as a unified system, to maximize performance and energy efficiency, minimize environmental impact, and accelerate widespread adoption of innovative combustion strategies. This effort represents a highly multidisciplinary collaboration with the Combustion Research Facility at Sandia-CA.

The Co-Optima Team: 9 national laboratories, 13 universities, and additional university and industry partners were brought in to respond to an open funding opportunity in FY2018

Traditional biofuels research has sought to develop biologically derived drop-in fuel replacements for fossil fuels. As the Co-Optima name implies, co–optimization of both fuels and engines could yield beneficial synergies. Engines are designed to run more efficiently on affordable, scalable, and sustainable fuels, while fuels are designed to work in high-efficiency, low-emissions engines.

With a goal of getting to better fuels and better vehicles sooner, we are addressing a number of questions:

- What fuel properties maximize engine performance?

- How do engine parameters affect efficiency?

- What fuel and engine combinations are sustainable, affordable, and scalable?

To address these questions we are taking a Fuel Property-Based, Composition-Independent Approach. We seek to identify blendstocks with desired properties that have a strong potential to be sourced from domestic biomass. We have made progress in a range of areas:

Combustion

- Provided new understanding of how fuel chemistry can enable highly efficient boosted spark ignition (SI) operation

- Developed a Merit Function that is a much more accurate predictor of engine efficiency than AKI (anti-knock index)

Fuel

- Identified five key chemical families that provide the key fuel properties needed for high-efficiency SI engines

- Formulated structure-activity relationships that describe how chemical functional groups impart important properties to fuels

- Identified blendstocks for SI engines with beneficial, non-linear blending behavior

Analysis

- Identified blendstocks with near-term commercial potential through comparative systems-level analyses of 23 metrics representing economic, environmental, technology, and market factors

Tools

- Developed new numerical algorithms and computational tools that accelerate R&D

Turf Algae and Bioremediation

Sandia is testing whether one of California’s largest and most polluted lakes can transform into one of its most productive and profitable. Southern California’s 350-square-mile Salton Sea has well-documented problems related to elevated levels of nitrogen and phosphorus from agricultural runoff. Algae thrives on these elements — a fact that causes environmental problems but could also be a solution to those problems. Sandia intends to harness algae’s penchant for prolific growth to clean up these pollutants and stop harmful algae blooms while creating a renewable, domestic source of fuel. This type of synergy could tip the balance of the technoeconomic analyses of whether algae can be a cost-effective biomass feedstock.

The U.S. Department of Energy’s Bioenergy Technologies Office (BETO) is funding Sandia’s Salton Sea Biomass Remediation (SABRE) Project because it will help determine whether algae can be a viable part of the solution to the nation’s need for diverse energy sources.

During the first phase, Sandia partnered with Texas A&M AgriLife Research to test whether a newer method of farming algae could be as productive as an older, more established method, specifically single species of algae grown in large open raceways. The newer farming method is called an “Algal Turf Scrubber” floway system, used for growing a collection of native algae species. As water is pulsed in waves across the sloped floway, the algae consume the nutrients, and clean water emerges from the lower end. The system operates using solar-powered pumps, requiring almost zero maintenance, except for periodic algae harvesting, which can be done using common farming equipment. Sandia designed the renewable power pump system that provides water to the floway. The technology and components of the floway were developed by a company called HydroMentia Technologies LLC.

Based on early results of the testing in Texas, turf scrubbers can produce a quantity of algae comparable to raceways and the algae’s thick texture also lends itself to easy harvesting.

Water from one of the three major tributaries of the Salton Sea flows into the 900-foot SABRE Project turf scrubber. Algae growing inside the scrubber system feed on and remove the chemicals in the water as it passes through.

Should the SABRE Project prove successful, it could provide a model of remediation for algae blooms nationwide.

Volatile Organic Signatures Research

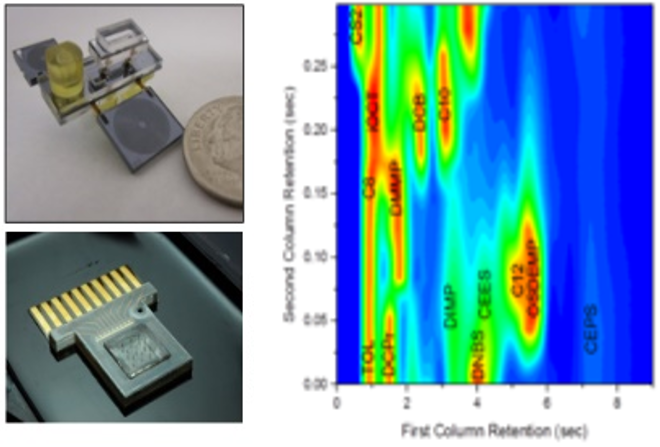

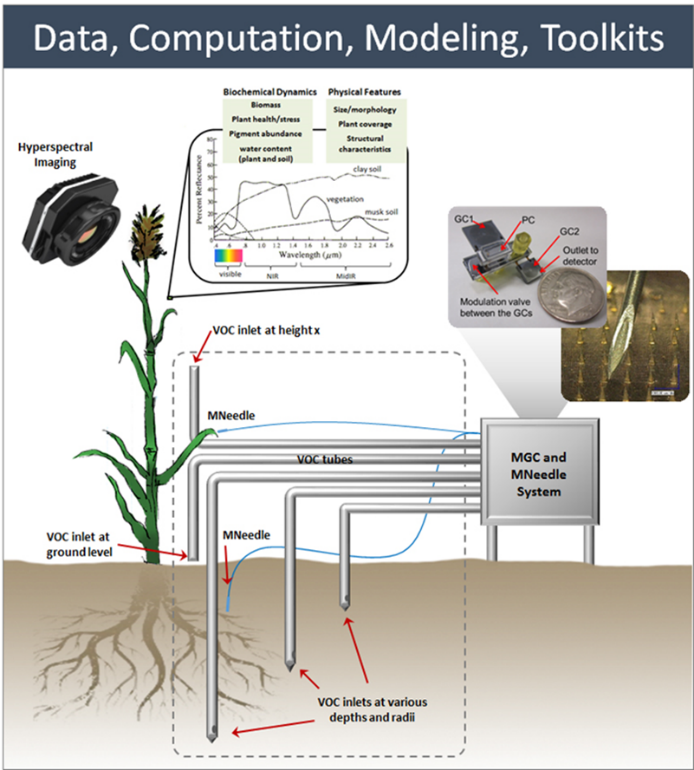

Sandia’s engineering and microfabrication capabilities have enabled the development of a number of miniaturized analytical components including micro preconcentrators, two dimensional micro gas chromatography devices (microGCxGC), microneedles with integrated sensors, and miniature gas sensors. These have been demonstrated in a variety of applications for drug, explosives, human performance and health monitoring and biogenic volatile organic chemical (VOC) detection.

DOE’s Advanced Research Projects Agency-Energy (ARPA-E) program known as ROOTS: Rhizosphere Observations Optimizing Terrestrial Sequestration has funded Sandia to adapt this technology and enable sophisticated measurements of agricultural crops in the field.

DOE’s ARPA-E ROOTS program has funded Sandia to combine GCxGC-TOFMS (dual gas chromatography – time-of-flight mass spectrometry), pattern recognition and machine learning to identify biogenic VOC signatures of the rhizosphere of plants. We are also developing microGCxGC detection systems to monitor the biogenic VOCs in the field, as well as advanced microneedle-based sensors to monitor plant health.

Sandia is adapting our existing Microneedle and Micro-Gas Chromatography technology to the study of agricultural crops. The goal of the effort is to develop new sensors and sensing techniques to monitor crop health and yield with the ultimate goal to reduce the water and energy requirements in farming.

The technology has been developed by Sandia for a wide variety of other applications and collaborations with partner universities, the University of New Mexico and New Mexico Institute of Mining and Technology, will help transition these technologies into the agricultural arena.

Microneedles and Microneedle Sensor Systems

Sandia is leading the development of microneedles with embedded sensors for plants (ARPA-E). In addition, models are being created to capture multi-omic data (or data from genomics, proteomics, and metabolomics) to build interaction networks and better understand the complex set of criteria at play in crop yield and plant health.

VOCs are sampled in the air above the plant as well as various depths in the soil near the plants’ roots. In addition, microneedles with embedded sensors are directly attached to the plants themselves, sampling fluids from the stem, leaf and root, for analysis. Collecting and collating the combined sensor data is providing exciting and beneficial new knowledge.