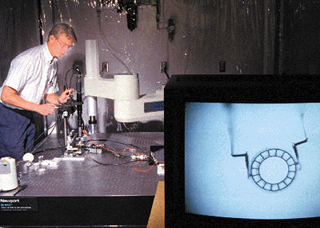

In optoelectronics and optomechanics manufacturing, precision assembly of increasingly small devices has become a critical capability. Microscopic machines are the focus of the High Consequence, Automation, & Robotics (HCAR) Precision Micro Assembly Lab. Created to investigate the automated assembly of microelectromechanical (MEMS) components, the laboratory is developing technologies for a robotic workcell that can assemble MEMS parts 10 to 100 microns in size, about the diameter of a human hair, into tiny machines for use in weapons components, surveillance devices, and microsurgery.

Technical Challenges

A major limiting factor in micro machine technology is the assembly process. Manual assembly is cost prohibitive and requires a level of precision that is impractical for an operator due to the eye strain and dexterity limitations associated with assembling such miniature parts under a microscope.

Features

The Precision Micro Assembly Lab is designed to make assembly easier and more cost effective, enabling the development of new applications for micro machine technology. The lab is able to assemble LIGA (Lithographie Galvanoformung Abformung) parts with 100 micron outer dimensions and 1-5 micron tolerances. The lab provides a rapid prototyping capability for the assembly of micro scale systems. The lab includes the following capabilities:

- State of the art motion control equipment including a robotic workcell with 40 nanometer position resolution

- Fully automated CAD-driven workcell

- Fourier optics methods to generate synthetic microscope images from CAD drawings to test image processing routines under varying magnifications and depths of field

- Custom designed micro tweezers and actuators

- Distance microscopes

- Laser interferometer equipment

- Thick film deposited strain gages for force feedback

- Real-time computer vision to control servo mechanisms and motors for the alignment and assembly of parts with sub-micron tolerances

- Scanning Electron Microscope

- 12 degrees of freedom nano manipulator

HCAR has demonstrated the automatic placement a LIGA gear with a 50 micron inner diameter hole onto a 44 micron post. The robot system can visually servo a 100 micron outside diameter LIGA gear to a desired x,y reference position.

Applications

HCAR is working to develop an assembly process where multiple gears can be placed on multiple posts in a single step. In this situation, a pin insertion tool press fits several 380 micron diameter pins into holes for a single wafer. This wafer is then mated to another wafer which holds multiple gears. The sandwiched wafers are removed from the workcell and placed in an etching bath where the gears are released from the second wafer. This process can be repeated to form gear trains and other complex mechanical structures.

As micro assembly processes advance, the development of increasingly smaller and more complex micro machines are enabled leading to the development of new applications and technologies, such as guided bullet technology. In addition to manufacturing, micromanipulation has potential applications in microbiology and microsurgery.

Contact Us

Questions and comments about High Consequence, Automation, & Robotics? Contact us.

Technology Transfer

The Precision Micro Assembly Lab is available for collaborative research in manufacturing applications such as fiber optic alignment, integrated circuit assembly, and computer related devices. For more information, please contact us.