B61-12 LEP milestones

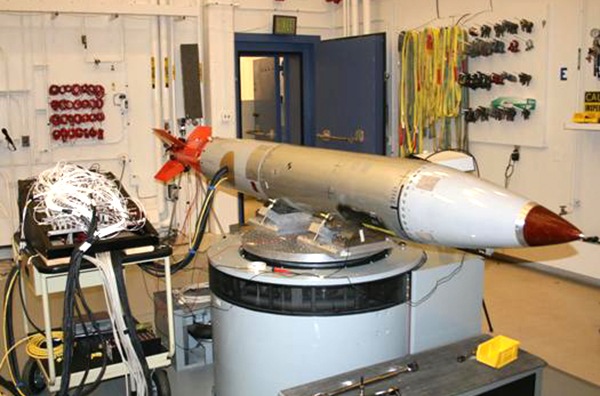

The B61-12 Life Extension Program successfully conducted Version 1.0 Technical Basis activities, including numerous functional, environmental, and flight tests. Notable achievements included vibration fly-around (VFA) testing and the FTDU (flight test demonstration unit) development flight test series. VFA tests were used to collect environmental data, and the FTDU series was used to test early War Reserve (WR) functionality and performance and ensure the joint test assembly configuration will adequately gather data during qualification flights. Numerous departments in Sandia and partner organizations contributed to these accomplishments. (2100, 400, 1300, 1500, 1800, 2900, 3600, 5400, 8100, 8200) NW, NW

The B61-12 LEP Credible Combinations of Abnormal Environments effort applied advanced uncertainty techniques to integrate subject matter expert judgment with tangible data. A probabilistic model of abnormal environment phenomena and weapon system response was developed to capture combined scenarios (with uncertainty) that could lead to an inadvertent nuclear detonation. Results will focus experimental and numerical resources to assess the B61-12 nuclear safety design in abnormal environments. This innovative approach was supported by experts from Sandia, Los Alamos National Laboratory, NNSA, and the US Air Force. (400, 1500, 2100, 8200) NW, NW

Sandia’s B61-12 Systems Team collaborated with partners across the National Security Enterprise to successfully meet several important program milestones on time and on budget, including the Flight Test Development Unit (FTDU) series. Two of the successful flight tests occurred in FY15, on July 1 and on Aug. 11. Organization 8130 designed, built, tested, and delivered the telemetry units and detonation monitor assemblies to support the FTDU development flight test series. The telemetry unit was used to monitor and confirm that all primary pre-arming, arming, fuzing, and firing functions were executed successfully. These measurements — and their successful transmission to ground assets — were critical to overall test successes. (8100) NW, NW

Sandia’s Aircraft Compatibility team from organizations in 2900, 1500, and 2600 successfully completed a rigorous four-week/eight-flight test to characterize flight environments of the B61-12 on NATO’s PA-200 Tornado aircraft (see image below). Analysis products from the test directly affect B61-12 development by defining design-level environmental specifications. Successful completion of the test is a key step in ultimately certifying compatibility of the B61-12 for wartime use with the PA-200. (2900, 1500, 2600) NW, NW

The High-Efficiency Adaptable Telemetry Transmitter (HEATT)

The High-Efficiency Adaptable Telemetry Transmitter (HEATT), being developed as part of the W88/Mk5 Alt 370 project, has been successfully tested in multiple flight tests for the Navy. HEATT is a small transmitter with improved power efficiency. Besides supporting W88 data transmission needs, HEATT is being assessed for use in other Joint Test Assembly designs. (2600, 8100, 1700, 2100) NW, NW

In FY14, one of the centrifuges used to simulate flight environments at the Weapons Evaluation Test Laboratory was taken off-line due to increased system vibration and loss of the drive system that provides power to the centrifuge motors. Expertise from across Sandia was used to fully diagnose the issues through extensive modeling, testing, and analysis. In FY15, a joint effort by Sandia, CNS Pantex, and Ideal Aerosmith Corporation resulted in a full recovery of the capability, stiffening the existing arm and replacing the drive system. (2900, 5300, 1800, 1500) NW, NW

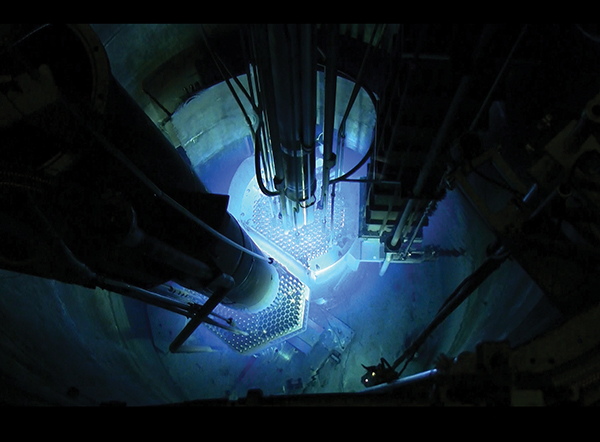

The Annular Core Research Reactor facility provided exceptional support to the Nuclear Weapons program by providing 536 operations in FY15, a 50 percent increase above average operations levels, to support important milestones. Additionally, the facility improved capabilities by restoring its neutron radiography capability, allowing experimenters to conduct detailed non-destructive component analysis, the Fueled Ring External Cavity capability, which provides experimenters with a larger dry experimental cavity, and operations at lower neutron fluencies by upgrading nuclear instruments, providing customers low-power operations five decades below previous capabilities. (Orgs 1380, 4128) NW, NW

Partnering with the production agency at Pantex and the National Security Campus (NSC — formerly the Kansas City Plant), Sandia’s on-site presence has strengthened relationships, as evidenced through semi-annual Quality Forums Sandia hosts at Pantex and Quarterly Joint Quality Managers’ meetings at NSC. The Pantex Quality Forum includes government, design, and production representatives across the entire Nuclear Security Enterprise (NSE). NNSA program leads and NSE directors gather with subject matter experts to identify specific and cross-cutting weapons quality topics, share information, and implement solutions. Recent forum topics have included production schedules and resource allocation across the enterprise. (0400, 2100, 2200) NW, NW

With more than 30 courses taught in FY15 and more than 4,400 attendees to date, Sandia’s National Security Quality Training (NQT) program expanded its course offerings in FY15 by 30 percent, including at other sites. New courses included Software Quality, Preventing Supplier Quality Problems, and Tester Qualification. With the high percentage of staff new to the Laboratories and a number of programs moving through critical phases of full-scale engineering development, consistent application of quality fundamentals enabled by the NQT program is central to success. (400) NW, NW

Neutron generators (NGs) must survive explosive shock long enough to provide neutrons. This survival time, referred to as standoff, is traditionally proved through tests called “hydros.” Due to programmatic considerations, hydros were not performed on a new class of NGs, although follow-on modeling predicted margin. To add confidence, NGs with delayed timer drivers were flown on Oct. 21, 2015, in JTA-331, a high-fidelity flight test unit. The neutrons measured by the Livermore raft system are consistent with expected results. Consequently, the use of a “flying hydro” provides confidence that the new W87 NGs have sufficient standoff margin. (8200) NW, NW

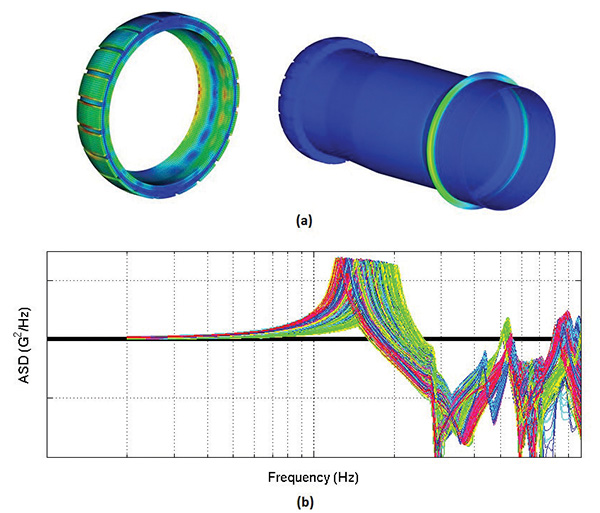

Example stress analysis (a) and random vibration excitation levels (b) for a conceptual mount design.

Advanced simulation and computing capabilities were used to provide a technical basis for a W80-4 delivery vehicle mount down-select recommendation to the Air Force. The design space for three different mounting configurations was explored through the use of parametric finite element models. Insight into the sensitivity of each design parameter and the resulting range of mechanical responses during shock and vibration loading was provided through thousands of simulations. The results characterize the adaptability of each mount configuration to a future delivery platform. (8200) NW, NW

Sandia has completed fabrication of the Group 3 Common Authentication Module Application Specific Integrated Circuit (CAM ASIC) using Sandia’s Rad Hard 350nm CMOS7 process. The CAM ASIC was designed for high-consequence applications. While the Group 2 CAM ASIC was fully functional, the Group 3 version uses Sandia’s complete Trusted Flow. A fully functional “Alpha” version of the CAM ASIC software has also been released. (1700, 2200, 2600, 6900) NW, NW

The Trust Enhancement (TE) team successfully completed a research and development project intended to both develop and implement a security enclave to protect against a broad spectrum of information security threats. TE is designed to enhance the trustworthiness of all facets of critical computing systems used at Sandia for engineering. The project implements trust engineering principles of assurance, isolation, and monitoring with the intent of providing a more secure system environment for these critical Sandia applications. (9500, 5600, 9300, 8900, 5900) NW, NW

A new detonator for the W80 ALT 369 neutron generator was successfully produced and qualified in October 2015, four months ahead of schedule. The achievement is notable because it is the result of an investigation and recovery effort in response to circumstances that affected the neutron generator first production unit delivery schedule. The Sandia investigation team employed a rigorous approach that used physical and numerical analysis to develop solutions to address concerns. (2500, 2700, 1300, 0400, 8200) NW, NW

The HERMES III (High-Energy Radiation Megavolt Electron Source) accelerator successfully fired its 10,000th shot on July 14, 2015. HERMES III began operation in early 1988 as part of the Simulation Technology Laboratory complex in Tech Area 4. It remains the world’s most powerful gamma-ray simulator, producing 13 terawatts of power in a 19-million electron volt, 28-nanosecond electron beam. It produces intense bremsstrahlung doses and dose rates over large areas to study nuclear radiation effects induced by gamma-rays. (1300) NW, NW (Photo by Randy Montoya)

John Clauss (2137) successfully led the W88 ALT 370 team to full integration of technical requirements, demonstrating that all requirements have been traced and flowed to major components using modern database tools. The completion of this significant milestone resulted in the project team gaining trust with customers and senior management. John provided vision, leadership, and the ability to execute under tight system engineering constraints. The effort required collaboration from a set of teams across Sandia, partner, and customer organizations including LANL, NNSA, and the Navy.