The Lifecycle Management Team

ELM/C&M/Production teams accept a new target loader at vendor, April 2016.

The highly motivated Equipment Lifecycle Management (ELM) team worked closely with its production and development partners to successfully deliver, install, and qualify 23 new pieces of equipment in FY16 to support complex processes such as evaporation and target loading, and highly specialized processes such as X-ray photoelectron spectroscopy. This equipment ensures needed availability and improved and updated functionality to the Neutron Generator Enterprise. (2700)

The Heterojunction Bipolar Transistor (HBT) Product Realization Team (PRT) delivered to the Kansas City National Security Campus the first compound semiconductor NW product from the MESA MicroFab. This delivery, two months ahead of schedule and on-budget, concludes several years of focused effort to transition this new technology into an NW-rigor production environment for current and future NW programs. Collocated design and production activities were key to meeting project milestones and laying the foundation for next-generation devices. (1700)

Sandia and Los Alamos National Laboratory completed the joint W88-0/Mk5 ALT 370 Preliminary Design Review and Acceptance Group (PDRAAG) review of the Preliminary Addendum to the W88 ALT 370 Final Weapon Development Report. This review was conducted by an independent DoD panel to evaluate the adequacy of the design meeting DoD customer requirements. Major milestones leading up to the PDRAAG included the System Baseline Design Review and the Inter-Laboratory Peer Review. The PDRAAG review is a prerequisite for Phase 6.4 Production Readiness authorization from NNSA. (200, 400, 1000, 2000, 5000)

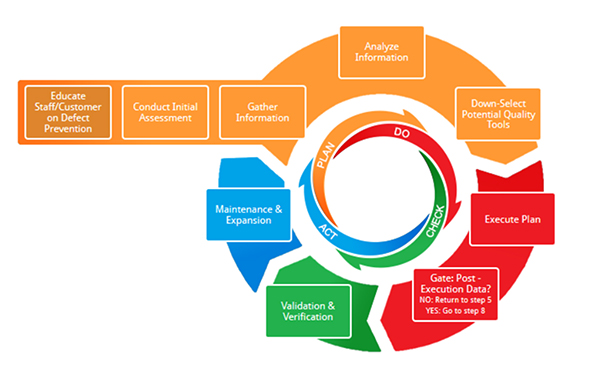

Defect Prevention

Defect Prevention is a methodology applied throughout the product development lifecycle to identify, analyze, and prevent defects from re-occurring. Defect Prevention has been successfully implemented across nine projects, a new class has been deployed (NQT610 – Defect Prevention), and 25 new Quality Tool Cards have been released to aid users in implementation. The formalization of the Defect Prevention methodology throughout FY16 enables both Nuclear Weapons and Strategic Partnership Projects to launch their own initiatives for high-consequence programs seeking defect reduction and elimination. (400, 1500, 2000, 5000, 6000)

The Neutron Generator Enterprise (NGE) met or exceeded all deliverable commitments in the FY16 NGE Integrated Program Plan. This included a record number of NG builds (854) representing nine NG products in development and production. Other noteworthy FY16 highlights for the NGE were the realization of $2 million in savings due to exceeding yield targets at various subassembly levels and the continued efficiency gains (doubled tooling capacity in the past two years) associated with the use of additive manufacturing to meet tooling needs. (2700, 400, 1500, 2100, 2500, 2800, 8200)

Sandia developed a state-of-the-art Additive Manufacturing laboratory that supports rapid product realization by providing agile, adaptive, and responsive manufacturing of parts used for engineering evaluations, demonstrations, and communication of design intent. An engineer’s digital model can now be directly manufactured on one of our laboratory’s nine printers, which are capable of producing 5,000 cubic inches of products every month in polymer materials such as ABS, nylon, ULTEM™, polycarbonate, and photopolymer resins with tolerances of +/-0.005” with greater than 95 percent accuracy. (2900)

NW SPRINT

CHALLENGE WINNERS – Student members of the NW SPRINT winning team pose with their trophy after judging on Aug. 4, 2016.

The Nuclear Weapons Summer Product Realization,Institute (NW SPRINT ) was officially recognized as a pipeline for prospective weaponeers. This institute was formed through a partnership of like-minded NW centersmin an effort to define a compelling project-based experience for uncleared interns and new-hires. Three teams designed an environmental sensing device, built it with additive manufacturing techniques, and tested it on amcentrifuge. The teams included 22 participants from 10 universities. NW SPRINT will now continue on an annual basis. (400, 2200, 2600, 2900)

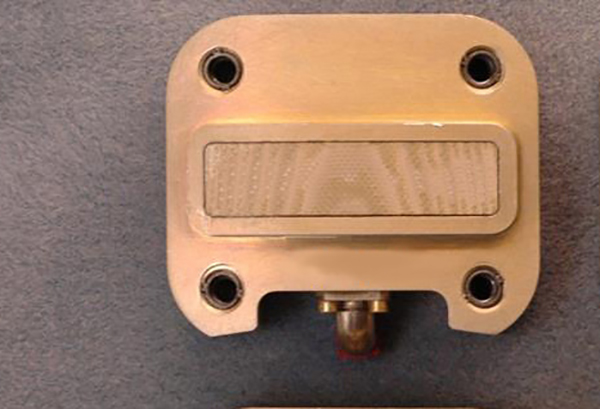

B61-12 Joint Test Assembly Antenna Element

The B61-12 Antenna Product Realization Team, consisting of team members from both Sandia and NNSA’s Kansas City National Security Campus, achieved Qualification Evaluation Release (QER) status for the B61-12 JTA antenna in December 2015 after completing all requirements necessary to verify that the component is ready to release to production. This is the first B61-12 component to achieve QER. The Antenna PRT has achieved this significant milestone under budget and ahead of schedule. (5300)

S-Series Actuators

Sandia S-series actuator Production Agency (PA), partnering with Los Alamos National Laboratory Design Agency, instituted enhanced mistake-proofing controls and increased technical oversight of external supplier manufacturing processes in response to ananomaly discovered during actuator lot acceptance testing. Following process-improvement implementation across all S-series products, actuator performance dramatically improved as evidenced by early pathfinder lots. Resulting product delivery delays were subsequently compensated for through close collaboration among all affected weapon complex agencies including Sandia, Los Alamos, Kansas City National Security Campus, and Savannah River Site. (2500, 2900, 400, 10200, 10600)