For many, explosives detection these days brings to mind fuzzy images of air travelers and long lines at the airport. But the serious hunt continues for better tools to detect explosives and the expanding range of compounds that can be used as explosives, with veteran Sandians creating more precise and elegant solutions for detection.

Sandia’s Contraband Detection Dept. 6633, a key contributor to the aviation and border security programs in the International, Homeland and Nuclear Security Strategic Management Unit, is working on the next generation of explosives detectors. Their work significantly advances existing explosive trace detection (ETD) technology and elevates their ability to help secure borders and transportation systems.

Though much of the recent attention on explosives screening at airports has emphasized the millimeter-wave imaging technologies for bulk detection of explosives, the use of ETD machines has expanded in the past year. The Transportation Security Administration (TSA) announced last year that it was purchasing 1,200 ETD machines to add to the 7,000 already in use in US airports. TSA screeners use trace detection technologies to look for the wispy residue of explosives left accidentally during the bomb-making process. They typically examine a person’s hands, shoes, hair, clothing, or baggage.

Working on a project for DOE, the Contraband Detection group is building a better ETD machine that will increase the number of detectable compounds. The current project builds on the group’s history of using preconcentration techniques to improve the chances for a detector to find explosives.

The result of the new research will be a more powerful and precise instrument for guiding first responders, customs officials, border guards, and others in their search for hidden danger in innocuous-looking containers or clinging to seemingly innocent people.

‘Reliable, useful and robust’

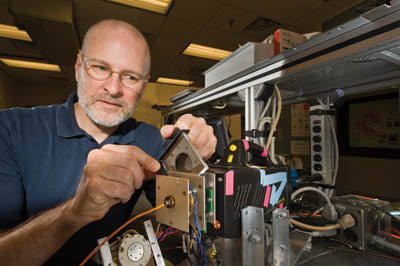

“Our aim is for this technology to be useful in the field,” says Charles (Chuck) Rhykerd Jr., (6633), a lead researcher on the project who is also the principal investigator for a related Laboratory Directed Research Development (LDRD) endeavor (see story at right). “We’re struggling with getting tools out into the field that are reliable, useful, and robust, taking into account the ideal size, weight, and performance for someone on the move as well as the challenges they face.”

The basis for Sandia’s ETD innovation is a heated metal screen and a process called temperature-stepped desorption. Currently, commercial trace detection technologies that use heat apply a small blast of heated air to a cloth swab that was rubbed on a suspect surface such as a briefcase, a shipping container, a truck bed, or a person’s hands or clothes. The heat causes explosive compounds to detach from the swab; a vacuum sucks the explosive particles into an ion mobility spectrometer, where they’re ionized and those charged molecules are then recorded.

Part of the problem with this approach is that explosive compounds compete for ionization loads, with some grabbing a greater charge than others. The ion mobility spectrometer interprets the ionization loads like a smoke detector that goes off whether it’s sensing a steamy shower or a candle-fueled curtain fire; it reports an imposing presence but it cannot differentiate the actual cause.

Replacing the cotton swab with a metal screen and the single blast of heat with a steady increase in temperature over time, creates a more differentiated environment for the compounds. The result is that different compounds, desorbing at different temperatures, lift off the screen and enter the chamber at different times, which then affects how they’re ionized and ultimately, how they’re interpreted. The process, which involves several new patents, was designed for and will be housed in commercially available ETD units. However, it builds on more than twenty years of trace explosives detection R&D, the kind of work that helps define Sandia as a national laboratory.