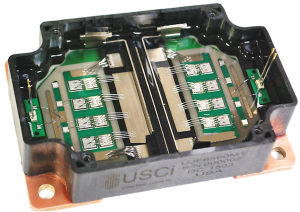

Technology: Fiber Optic Electrical Current Transducer

Developers:

The Fiber Optic Electrical Current Transducer is an optical current sensor that measures current, magnetic fields, and ambient/conductor temperature in high-power applications with increased safety, isolation, and lower installation costs than conventional technologies. The FOECT measures the magnetic field surrounding or current flowing through a conductor, simultaneously providing temperature. It was designed to replace existing current transducers in applications ranging from monitoring load currents in electrical power lines to providing feedback information in high-energy power electronic converters.

Developers expanded upon how it is not necessary to completely encircle the conductor that is being monitored. Rather than perform an integration of the magnetic field, the sensor samples a point in the field using an optical crystal at a predetermined location. Through Faraday rotation of the polarized state, developers measured the strength of the magnetic field, extracting the temperature from fluctuations in the rotation angle.