A nuclear weapon has a life cycle just like a person. But the aging process is harder to weigh. When is old too old? Time will tell.

It’s complicated, making sure a nuclear weapon will work as designed.

A 1992 moratorium that ended decades of large underground nuclear tests, an aging stockpile and the need to refurbish weapons have transformed what’s known as stockpile evaluation or integrated surveillance.

Sandia National Laboratories, which is responsible for some 97 percent of the non-nuclear components of nuclear weapons, tested components in various ways even before the moratorium. Sandia’s core mission is nuclear weapons, and over the years, it has developed ever-more sophisticated tests and increased computer modeling and simulations to qualify nuclear weapons — certify they will work as designed but won’t work in an accident or when they’re not authorized by the president, says Scott Holswade, Sandia’s deputy chief weapons engineer.

Three years ago, Sandia formed a Research Challenge, Revolutionary Approaches to the Stockpile, to bring together a variety of experts to address, among other things, how to ensure a thorough understanding of how weapons age and what that means for a smaller, older stockpile. Research Challenges are longer-range projects that address important national security questions.

The Department of Defense (DoD) and the Department of Energy (DOE) set requirements for weapons. Sandia must consider all the environments weapons could face, such as vibration or radiation, then come up with designs to handle those and tests to make sure designs meet requirements, says Toby Townsend, stockpile systems engineering senior manager. Once weapons enter the stockpile, Sandia must continue testing to assure they meet requirements as they age.

Typically, a weapon has a so-called protected period, the lifespan it’s designed for — 20 years, for example. Engineers certify it through such processes as accelerated aging, using environmental test chambers to speed up conditions the weapon could face over time.

“We’re often asked, ‘How much longer could the weapon potentially be good for?’ That’s a major part of the stewardship mission,” Townsend says.

Stages of the life cycle

At one time, most weapons were either newly in production or fairly early in their life cycle and were retired before they aged much more than about 10 years. Now, the stockpile includes systems that have been there for decades and newly refurbished weapons that reuse some older parts with some new ones.

“A pediatrician does not look at the same things that a geriatrics expert would. The things you’re looking for in ‘pediatrics,’ the defects in design and production, are different than if you’re looking for aging effects for something late in its life cycle,” Holswade says. “I think that’s been the big evolution of the program, to start implementing changes that recognize this and the need to change the program to optimize for each system, depend-ing on where it is in the life cycle.”

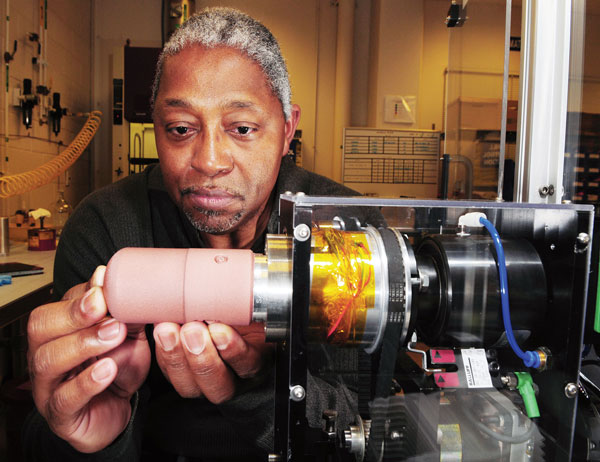

A weapon coming into the stockpile, such as the refurbished W76-1, is tested at very high rates to catch possible design or manufacturing defects. However, the question is different for a weapon that’s been in the stockpile a while: How does aging affect it?

Jay Vinson, senior manager for Integrated Stockpile Evaluation, says assessments of the non-nuclear systems include laboratory testing, largely at the Weapons Evaluation Test Laboratory (WETL) at the Pantex Plant near Amarillo, Texas. Assessments also include non-nuclear system-level flight testing of gravity bombs at Tonopah Test Range in Nevada, cruise missiles at the Utah Test and Training Range, Air Force ballistic missiles flown into the Pacific from Vandenberg Air Force Base in California and Navy submarine-launched missiles flown in the Atlantic and the Pacific, he says. Numerous places, including Sandia, the Kansas City National Security Campus and WETL, do component tests.

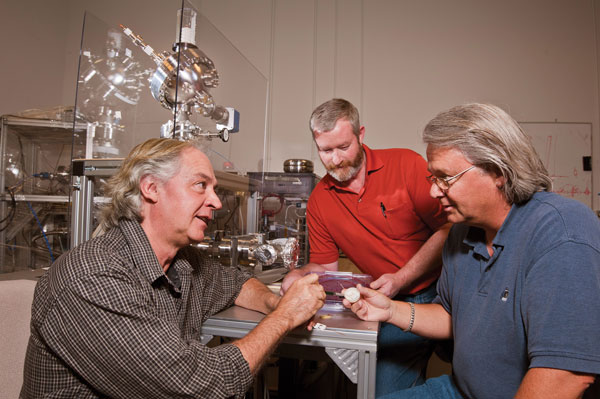

During development of modifications such as a life extension program or an alteration, tests qualify individual components up to whole systems. “There will be temperature cycling, there’ll be vibration, there’ll be shock, there will be radiation, there might be voltage changes, all kinds of things that the system is subjected to, done in accordance with a plan that combines testing with simulation to make sure we’re working through in a systematic way what’s required to qualify the weapon for operation,” Holswade says. “The goal is absolute certainty that the design is good to perform.”

Tests and more tests

Once production begins, the program must assure the as-built weapon conforms to the as-designed weapon. “You can have production errors, or you may have missed something in the design process that only reveals itself as you get to higher volumes,” Holswade says.

Vinson says that as production ramps up, Sandia does more retrofit evaluation sample testing, pulling units before they go into the stockpile to catch possible production errors or early-onset failures.

Weapons also are pulled from the field to test later when they’ve been handled by military personnel and might have been on a submarine or missile. At that point, engineers want to study whether field conditions exposed a problem.

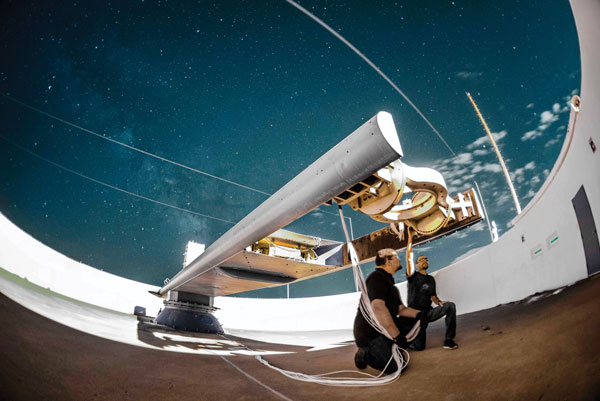

Some weapons from the field are built into joint test assemblies, mock weapons without nuclear materials but fitted with sensors and instrumentation to assess performance. Flight testing is part of the qualification process for refurbished weapons, and its main objective is to obtain reliability, accuracy and performance data under operational conditions. Scientists and engineers use the test data in computer simulations developed by Sandia to evaluate systems’ reliability and to verify they functioned as designed.

The W80-1 Air Launched Cruise Missile Surveillance Flight Test Program fielded a joint test assembly in June, simulating a long flight to a target and performing arming maneuvers. “In this case, the nuclear explosive package is replaced by the testing assembly, so the system won’t detonate, but it will function with all the Sandia componentry along that trajectory,” Vinson says. “The various safety functions and other weapon functions will occur as if it were a wartime environment. We want that to all work properly because it indicates we have a safe and reliable weapon.”

Weapons in some flight tests have high explosives that detonate, with instruments sending out data during flight. In other cases, instead of explosives, sensors in the system check that the detonation chain would function. Instruments send out the data during flight but engineers recover that system afterward for further diagnostics. For B61-12 flight tests at Tonopah, real-time telemetry data gathered during flight tests are monitored and verified at the range’s Test Operations Center and main telemetry ground station and sent to Sandia in Albuquerque.

“We can’t fly every potential trajectory because you’re limited by where you can launch from and where you can land. We can’t fly every weather condition because you’re stuck with the weather you have when the flight’s scheduled,” Holswade says. So engineers do additional tests on components and subsystems for those “corner cases” — like the hottest day with the biggest shock condition or the coldest day with more vibration.

Simulation anchored by experimental data

Sandia’s large environmental test facilities can evaluate components under a wide range of conditions. That doesn’t mean testing is easy — combining environments is especially challenging. Engineers might test how well a component works in a radiation environment, but it’s difficult to combine radiation and shock testing, for example. So researchers use simulation anchored by experimental data. That lets researchers assess components when it’s not realistic to test every possible scenario, Townsend says.

“It gives us a lot more confidence across the spectrum of environments,” he says.

Because Sandia is responsible for nuclear weapons parts that must have a high degree of reliability, materials scientists, engineers, computer scientists, modelers and others also are working on projects under a separate Research Challenge, Engineering of Materials Reliability. That program is focusing efforts on understanding how the variability of materials can affect stockpile performance, with the goal of building a foundation to understand and predict the limits of a material’s performance and its contribution to reliability of engineered structures.

“Sandia has to guarantee the part works for decades,” says Amy Sun, a member of the leadership team for the research. “It’s an inherent challenge to understand how materials perform, under what conditions a material changes its property and whether a part we want to design can tolerate those changes that come naturally with aging or an external influence like the weather. It’s important we invest early to anticipate what problems there may be in the future.”

The Research Challenge incorporates and broadens many materials and engineering efforts, including Sandia’s Predicting Performance Margins project and other Laboratory Directed Research and Development and Advanced Simulation and Computing activities that study how variability in materials’ atomic configurations and microstructures could affect how actual parts perform. It includes several demonstration projects, including the Brittle Materials Assurance Prediction initiative, which is studying the properties of materials such as glass that can fail catastrophically, and “Born Qualified,” which is look-ing at new materials challenges and opportunities posed by additive manufacturing.

“We consider stockpile stewardship as our most important mission for engineering materials reliability, but we know that it’s relevant to all mission areas at Sandia where materials reliability is one of the requirements,” Sun says.

Meet Kina Winoto

In high school, Kina Winoto wanted to be an FBI agent or join the military. She thought about the Naval Academy for college. “Weirdly enough, I always wanted to work for the government,” she says. Her parents urged her to wait to enlist, so she enrolled at the University of California, Los Angeles.

She was drawn back to government after graduation and did an internship at the Department of Defense, where she heard about Sandia Labs and its national security mission. “That really resonated with me,” she says. “I homed in on that type of work.”

Winoto’s role model was her dad, a molecular cell biology professor at the University of California, Berkeley. “He tried really, really hard to get me into science, and it was fun,” she says. “I have great memories of experiments and Lawrence Hall of Science camps and science fairs. He pushed me to ask questions.”

Winoto took her first computer science class as a high school freshman. Another was offered her sophomore year, but that was it. She wanted to know more and enrolled in computer science in college. “I didn’t get enough in high school,” she says. “I remember a moment in my third year of college when I thought, ‘Wait, am I majoring in computer science?’ I hadn’t really thought about it. I just kept wanting to learn more.”

Winoto joined Sandia in 2012 and earned her master’s degree through the labs’ Critical Skills Master’s Program. She works in cybersecurity where her focus has been on integrating state-of-the-art techniques with mission-critical data. A lot of her work has been in data analytics in the cyber application space. But Winoto is a jack of all trades, having worked in everything from software development of big data processing tools to applied statistics. She’s working now on bringing numerical linear algebra techniques to mixed-type datasets to let analysts more efficiently identify anomalies.

In her spare time Winoto raises and helps train guide dogs for the blind. She builds furniture with her fiancé and does acroyoga, which combines yoga and acrobatics.

“Sandia has really shaped my career as a data scientist and inspired me to work on mission-critical problems.” she says. “On the path I’ve taken, every day brings new and exciting discoveries.”

— Nancy Salem