Predicting the limits of friction on metals

See also: Pure serendipity led to discovery

Normally, bare metal sliding against bare metal is not a good thing. Friction will destroy pistons in an engine, for example, without lubrication.

Sometimes, however, functions require metal on metal contact, such as in headphone jacks or electrical systems in wind turbines. Still, friction causes wear and wear destroys performance, and it’s been difficult to predict when that will happen.

Until now.

Sandia materials scientists Nicolas Argibay and Michael Chandross and colleagues developed a model to predict the limits of friction behavior of metals based on materials properties — how hard you can push on materials or how much current you can put through them before they stop working properly. They’ve presented their results at invited talks, most recently the 2016 Gordon Research Conference on Tribology, and in peer-reviewed papers, including a recent article in the Journal of Materials Science.

Their model could change the world of electrical contacts, affecting industries from electric vehicles to wind turbines. Understanding the fundamental causes of failure in metal contacts allows engineers to step in and fix the problem, and potentially lights up more paths toward new materials designs.

Linking science, engineering applications

“It’s a tool to do design and it’s a tool to do science,” Nicolas says. “It’s really that link between fundamental science and engineering applications.”

The discovery of how to predict the friction behavior of metals began as a study of specific materials for projects.

“It’s a moment where you go from just having to say, ‘The materials behavior will be this because we measured it in those conditions’ to saying, ‘I can tell you what conditions you can run in and get the behavior you want,’” Nicolas says. “In fact, we provide guidelines for developing new materials.”

Designers choose materials based on engineering rules of thumb under certain operating conditions, using the conventional wisdom that harder materials create less friction.

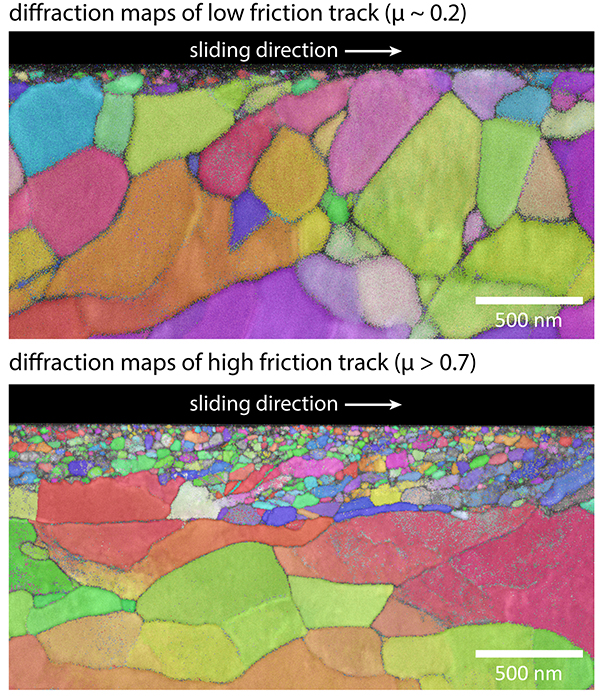

But Sandia’s research demonstrates the stability of the microstructure governs the friction behavior engineers care about, and that changes how engineers can think about design when they characterize and select materials, the researchers say.

The team studied pure metals, such as gold and copper, to break down the friction problem by looking at the simplest systems. Once they understood the fundamental behavior of pure metals, they say, it was easier to demonstrate that these ideas apply to more complex structures and more complex materials.

The idea developed in a convoluted fashion, starting several years ago when Michael was asked for simulations to help improve hard gold coatings — soft gold with a minor amount of another metal to make it harder. Gold is an efficient, corrosion-resistant conductor, but generally has high adhesion and friction — and thus high wear.

That project produced a paper that excited Nicolas, who told Michael he could do experiments to prove the concepts the paper described.

“From those experiments, the whole thing exploded,” Michael says.

“We looked at the pure metals as a way to validate some of the hypotheses we had from Mike’s analysis of more complex systems,” Nicolas says. “If these ideas work in more complex systems, they ought to work in the most difficult scenario, the least likely scenario conventionally, and they did.”

Sandia’s work has implications for the growing worlds of wind turbines and electric vehicles, where companies seek an edge over the competition.

The demand for electric cars and alternative ways of making electricity are likely to expand, creating demand for new technologies.

Nicolas is helping design and develop a prototype rotary electrical contact for wind turbines in a Laboratory Directed Research and Development (LDRD) project led by Wayne Staats. The initial concept came out of an earlier LDRD project led by Jeff Koplow.

“Basically we’re bringing back technologies that were discarded because they didn’t really understand the materials and couldn’t make them work where and how they wanted to,” he says.

New projects ongoing

The project is exploring copper against a copper alloy for a high-performance, efficient electrical contact. That could allow the wind turbine industry to explore designs that weren’t possible before.

In addition, the electrical contacts industry, which now uses alternating current in devices, might finally be able to turn to direct current devices as higher-performance alternatives. As a possible interim step, Sandia researchers are exploring metallic electrical contacts as a drop-in for some applications, avoiding major changes in how the devices work.

If they demonstrate the theory is sound, then engineers can change how they think about the fundamentals of design in some of these devices, they say.

Follow-up funding allowed the team to study the variable of temperature, and now Michael has begun an LDRD project to look at metals with other structures. Previous work has been done with face-centered cubic structured metals. His project seeks to understand friction in body-centered cubic metals, BCC metals, most commonly used for structural purposes. Researchers are looking at iron and tantalum.

Conventional wisdom holds that BCC metals won’t produce low friction. “This is one of those instances where understanding the molecular scale or atomic scale mechanisms caused us to say, ‘Yes, but they’re bad only if you’re not in the right conditions.’ What happens when you are in the right conditions?” Michael says.

?BCC metals could open up more design and engineering possibilities for wind power generation and electric vehicles, improving efficiency and ultimately reducing maintenance and manufacturing costs.

Pure serendipity led to discovery

Sandia researchers who came up with a model to predict the limits of friction behavior in metals are “happily defying conventional wisdom and a hundred years of publications,” Nicolas Argibay says. Those publications include a seminal paper from the 1930s in Nature that basically states pure metals have high friction and therefore are terrible for all kinds of uses.

Over the next 80 years, there were sporadic reports of experiments that showed low friction in pure metals “but they reported it as a curiosity, something strange that happened,” says Nicolas’ colleague, Michael Chandross. “They mentioned it one sentence in a paper, no explanation of why, no looking at it, just saying, ‘Yeah, this happened sometimes, that’s weird.’”

In the course of looking up a paper for their study, Michael and Nicolas stumbled across another paper about low friction in pure metals. It was pure serendipity that the end of the second paper was photocopied with the beginning of the paper they had sought. “I looked at Mike like, ‘We’ve got to find that paper!’” Nicolas recalls.

“When we pulled that paper and read it, sure enough, it was conditions that we now understand why they worked. They happened to hit conditions that were right on the cusp of what we reproducibly have done – and can now explain,” he says.