Sandia injector is key to validating plutonium pit performance

One thousand feet below the ground, three national defense labs and a remote test site are building Scorpius — a machine as long as a football field — to create images of plutonium as it is compressed with high explosives, creating conditions that exist just prior to a nuclear explosion.

These nanosecond portraits will be compared with visuals of the same events generated by supercomputer codes to check how accurately the computed images replicate the real thing.

“It’s clear we need to know that the stockpile will work if required,” said Sandia project lead Jon Custer. “Before President Bush’s testing moratorium in 1992, we knew it did since we were physically testing. Now we have computer codes. How well do they predict what really happens? Do we have accurate data we put into the codes? To answer these questions with higher fidelity, we need better experimental tools, and Scorpius is a major new experimental tool.”

The $1.8 billion project, combining the expertise of researchers from Sandia, Los Alamos and Lawrence Livermore national labs with support from the Nevada National Security Site — a test area bigger than the state of Rhode Island — is expected to be up and running by late 2027.

Tickling the dragon’s tail

“We intend to use Scorpius’ actual images, gained from what we call ‘tickling the dragon’s tail,’ to check our computer simulations,” Jon said. “These simulations theoretically describe the hydrodynamics of plutonium in its various states, and we want to see how closely they match.” Hydrodynamics here refers to material compressed and heated with such intensity that it begins to flow and mix like a fluid.

Tickling the dragon’s tail in this case means designing experiments that approach but stay below the threshold of criticality — that is, always subcritical, involving less than the mass needed for an explosion — while enabling a study of plutonium in that highly compressed and thermally heated state.

Aboveground facilities have tested the explosive behaviors of surrogate materials, but the inherent differences with plutonium cannot be accurately accounted for. While Scorpius will produce X-ray images during full-scale testing of plutonium, facilities that are equivalent but aboveground, including the Dual-Axis Radiographic Hydrodynamic Test machine at Los Alamos, instead must use implosionlike episodes to test the behaviors of surrogate materials.

“Plutonium is a very strange element,” Jon said. “There is no true surrogate. Nothing else behaves like it.

“So, the question to us is, are we feeding accurate data into our codes about plutonium’s behavior?” he said.

To find out, Scorpius, the buried interrogating machine, will produce X-ray images of plutonium as it implodes, with experiments specially designed to remain subcritical.

Three questions for Scorpius

First, researchers want to evaluate the effect of aging on plutonium to continue to validate that the U.S. deterrent will be effective if called upon. Plutonium, which transmutes from uranium, ages through a process called radioactive decay. Many nuclear weapons have been in service for thirty to fifty years.

“If you had a car in a garage for thirty to fifty years and one day you insert the ignition key, how confident are you that it will start?” Jon said. “That’s how old our nuclear deterrent is. It has been more than 30 years since we conducted an underground nuclear explosive test. And cars are mass-produced by the millions, with every problem well exposed. Our deterrent is built individually, one at a time. So, we want every assurance of reliability to warn potential adversaries that the U.S. stockpile remains a credible deterrent, now and into the future.”

Second, he says, consider weapons built since the underground nuclear explosive testing moratorium declared by President George Bush in 1992. The issue here is to show that changes in designs from 1992 to the present that were linked to physical tests of the past are just as potent, if not more so, than their underground-tested ancestors.

Finally, the congruence of theoretical and physical processes in both these test series, providing theoretical validation with Scorpius data, will help remove doubt about future simulations. These subcritical tests with Scorpius are expected to show that newly designed weapons of the future will function if called upon, even though constructed mainly from supercomputer designs and potentially significantly altered to overcome the changes in overall environments expected from the use of new materials and unanticipated electronic advances.

Daniel Sinars, director of Sandia’s Pulsed Power Center, said, “We are entering an era where our modernization programs are going to start making significant changes to the nuclear explosive packages, even if the performance characteristics of the weapons don’t change. That is, they are not ‘new’ weapons, but they may have a lot of new technology.”

“Having Scorpius is part of what will be needed to have an agile and responsive stockpile for weapon design that can qualify such changes in the absence of underground testing,” Dan said.

Programs to modernize the U.S. stockpile currently can take up to 15 years to execute.

“If instead we wanted to develop a new weapon or modernize them in more like five years, we will need capabilities to quickly assess design changes and risks for new hardware options,” Dan said. “Scorpius is part of a suite of capabilities that the weapon science folks envision as critical to going faster.”

Josh Leckbee, who led the injector development and design for Scorpius, confirmed that requirement.

“One of the key benefits and drivers for needing the Scorpius capability is to give confidence in existing and new designs,” Josh said.

“All the existing weapons in the stockpile have traceability to underground testing. It will be difficult to put weapons with new designs that are not directly tied to underground testing into the future stockpile,” he said. “To do this, we’ll need extreme confidence in our predictive modeling capability. Scorpius allows diagnosing of subcritical tests to build that confidence.”

In short, said Dave Funk, vice president for Enhanced Capabilities for Subcritical Experiments at the Nevada National Security Site, “The specific goal of ECSE is to understand the hydrodynamics of plutonium and validate current models of plutonium behavior with the goal of certifying the changes to the nuclear stockpile without the need to return to underground testing.”

“We are looking forward to establishing this capability in 2027, conducting the first subcritical experiments using these new capabilities to support our nuclear deterrent and demonstrate once again our technical prowess as a nation,” Funk said.

The most complex part

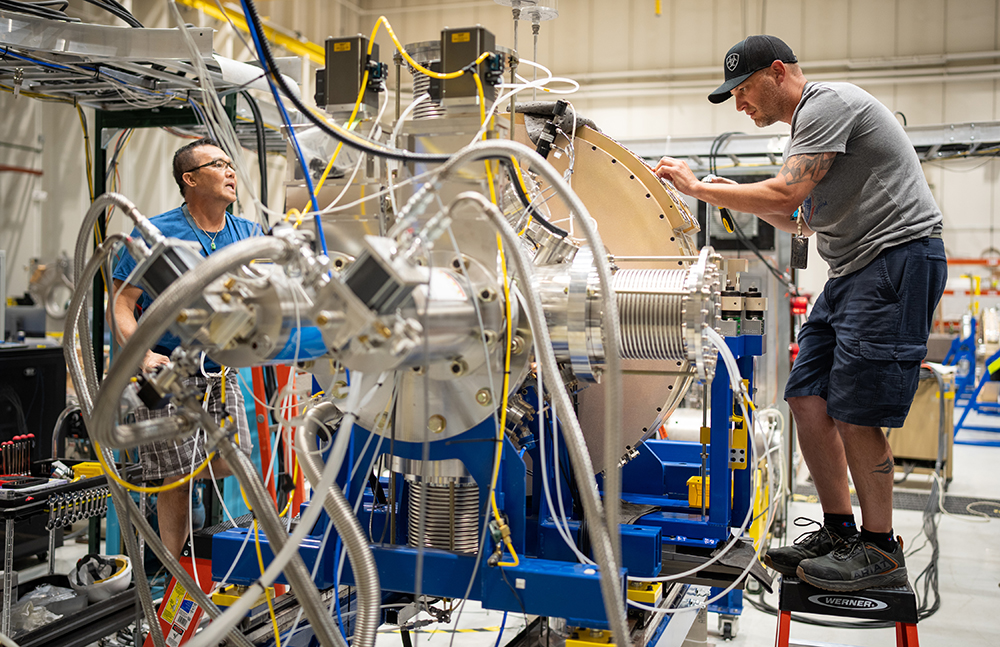

Sandia’s role in the Scorpius project is to design and construct the electron beam injector that will occupy the first 45 feet of the big machine, Jon said. “Much of the rest is to accelerate our electron pulses up to their final energy before slamming them into a heavy metal target to create the very bright X-ray flashes that will take the pictures.”

Stainless steel tubes able to maintain high vacuum levels inside the machine will transport electrons, aluminum will be used where possible for its lower weight and lack of magnetic susceptibility, and magnets will focus the electron beam. “Lots of vacuum pumps, sensors, wiring for power and signals, water lines for cooling, et cetera,” Jon said.

The machine will be able to produce four separate 80-nanosecond pulses of electrons at 1,400 amps per pulse. Those four pulses can be produced anywhere the experimenters want over a three-microsecond window.

Demonstrating that the injector is capable of four independent pulses was a key part of the technology maturation that the team has been doing for the last several years to be ready for this phase of the project.

“Being able to see multiple images in time as the device implodes really puts the computer codes to the test,” Jon said.

Sandia’s resume fits the job because of the Labs’ long-standing expertise in pulsed power. Its Z machine, Saturn and Hermes-III are three of the five largest pulsed power machines in the world. Sandia has made pulsed electron beam machines and done novel experiments in radiography with its series of Radiographic Integrated Test Stand accelerators, an ancestor of the current project and jointly developed by Sandia and Nevada.

Los Alamos is responsible for post-pulse acceleration — taking the beam from 1.7 megavolts up to 22 megavolts — and for turning the electrons into X-rays downstream, as well as for the X-ray camera system. Los Alamos also oversees integration of all the components into a functioning system ready for experiments, Jon said.

Lawrence Livermore will provide the pulsed power for both the injector and the accelerator. They also have responsibility for several of the injector subsystems.

“It is worth noting that Scorpius is based on ‘solid state’ pulsed power promoted by Lawrence Livermore,” Dan said. “That means that the initial pulses of electrical energy are coming from large numbers of circuit boards rather than the big banks of massive capacitors, or Marx banks used by Sandia’s Saturn and Z, and that was Lawrence Livermore’s primary contribution to the injector.”

Personnel at the Nevada National Security Site have helped all parties with design and testing, will assist with assembly and ultimately will be the owner and operator of the system in the underground U1a Complex. They are also doing extensive construction to prepare the space where Scorpius will be installed.

Plans for the complicated project were the focus of nearly 10 years of proposals modified, discarded and accepted through a multistage DOE Critical Decision vetting process that finds and removes conceptual and technical errors before funding can be committed to the project. Final approval came late last year.

To design the injector responsible for creating the images was an engineering challenge. “No data existed to guide multipulse high-voltage design and no multipulse high-voltage test capability existed to conduct experiments,” Josh said. “We teamed with the beam physics group at Lawrence Livermore, who led electron beam optics design and simulation for the injector.” The Sandia mechanical engineering team dedicated more than 30 individuals to developing creative solutions to manage competing requirements in high voltage, thermal, structural, alignment, vacuum and space constraints, Josh said. “The resulting injector design is an assembly with over 1,000 unique part drawings.”

“Our first shipment of injector components is slated to be sent out in March of 2024 when our assembly space in Nevada is ready, with the last shipment by early 2025,” Jon said. “Assembly and testing will take until the fall of 2025 when we will turn the injector over to Nevada. They will then move it underground into the U1a facility at the [Nevada] Test Site in 2026 or 2027.”

“I think I’m biased,” Jon said, “but, yes, I think the injector is the most complex part of the whole system.