Safety feature available for licensing to manufacturers

Sandia continues to innovate the use of hydrogen as a fuel source in vehicles and vessels with a newly developed safety feature that is ready for licensing to manufacturers.

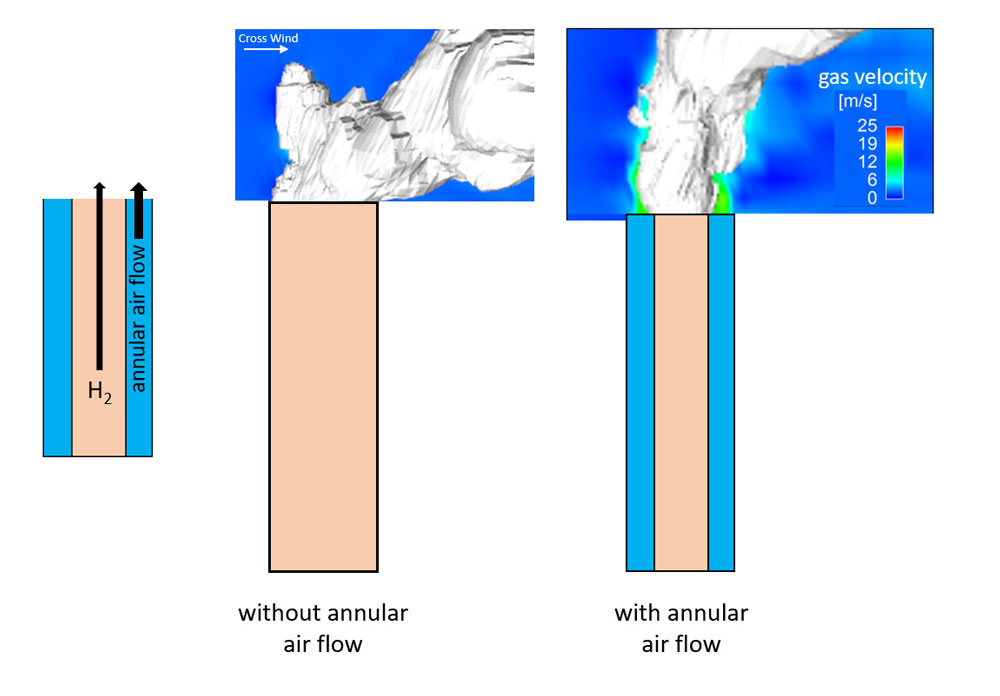

The Flow Assist Vent Mast was developed to replace the simple metal-pipe vent mast that is ubiquitous at hydrogen stations and other facilities handling lighter-than-air gases. The new approach introduces two active functions to venting such gases: dilution and dispersion, which make sure potentially flammable vapors are kept away from people and structures.

Physical chemist Lennie Klebanoff and fluid dynamicist Myra Blaylock investigated the design for seagoing vessels that takes planned or accidental hydrogen releases up and away, dispersing the flammable vapors away from passengers and the ship’s superstructure.

“Hydrogen-powered vessels could store high-pressure hydrogen in a composite tank that resembles a SCUBA tank, or the hydrogen could be liquified in cryogenic tanks,” Lennie said. “For either case, we want to be ready for planned and unplanned hydrogen releases. You might get releases in routine maintenance when you need to empty a section of pipe to service it. But there can also be emergency cases where you have to empty the hydrogen tanks rapidly.”

But venting hydrogen is not as simple as just installing an empty tube to the air well above the ship’s superstructure.

A breath of fresh air

“What this invention does is force peripheral air from around the side of this pipe into the vent mast exit so that the released hydrogen is mixed with a lot of air, diluting the hydrogen to below the 4% flammability threshold in the exiting plume, reducing the risk of combustion. That’s the first active improvement made over having an empty pipe,” Lennie said.

Hydrogen is the lightest gas, which helps it disperse as it rises in heavier air, improving safety. However, that weight also introduces a problem.

“Hydrogen molecules are very light, so they get pushed around by heavier air molecules,” Lennie said. “This is a problem if the hydrogen exiting the vent mast encounters downward pointing winds, which can push the hydrogen down towards passengers, crew or vessel structures. Having a peripheral flow helps the hydrogen plume overcome any downward-pointing wind, pushing the hydrogen up and away, while also diluting it.”

Myra quantified this idea by modeling how the Flow Assist Vent Mast would function in a windy environment, confirming the peripheral air flow would work to increase the vertical momentum of the hydrogen molecules while also diluting their concentration in the air flow.

“The Flow Assist Vent Mast would be both shorter and safer,” Myra said. “I used Sandia’s state-of-the-art Sierra Toolkit for computational fluid dynamics to analyze the very complicated flow in this system.”

(Illustration by Lennie Klebanoff)

Sandia to the fore

Hydrogen vessels are not just future tech. Former Sandian Joe Pratt who, along with Lennie, discovered the technical feasibility of hydrogen fuel cell vessels, founded the company Zero Emission Industries, or ZEI. With $3 million in funding from the California Air Resources Board, Pratt launched the hydrogen-powered ferry Sea Change in 2022. The Sea Change will begin to ferry the public around the San Francisco Bay this summer.

“It’s the first hydrogen-powered vessel that’s gone all the way through the U.S. Coast Guard gauntlet of regulatory approval, and its hydrogen propulsion approach is based on our work together at Sandia,” Lennie said. “The Sea Change is the first commercial hydrogen fuel-cell ferry in the Western Hemisphere.”

Lennie said that Pratt’s confidence to take entrepreneurial leave to establish ZEI — along with Sandia’s established partnerships with the U.S. Coast Guard, the Department of Transportation’s Maritime Administration, or MARAD, naval architects, and hydrogen fuel suppliers — tremendously shortened the commercialization time from the feasibility study to having a vessel on the water.

Since 2016, Sandia has performed feasibility studies on hydrogen-powered vessels, most recently with Scripps Institution of Oceanography, which wanted to launch the world’s first hydrogen-powered research vessel. That concept received approval from California lawmakers who awarded the project $35 million to design and build a liquid hydrogen hybrid research vessel based on a design created in a MARAD-funded Sandia project involving Scripps and naval architect Glosten Marine.

“The Sandia feasibility work gave Scripps the confidence such a vessel was possible, and the relationships we had already established with the Coast Guard, naval architects and the gas suppliers created the calm seas needed for the State of California to want to fund it,” Lennie said.

Sandia’s history with hydrogen

Myra said that work was also made easier because the Labs have logged decades of study in alternative fuel systems, including hydrogen.

“The nation is already moving toward a green economy, and I see our project, and this invention itself, as part of Sandia’s work to make alternative fuels safer and easier to use,” she said. “By using a Flow Assist Vent Mast, the venting structure can be shorter, lighter, and safer, which makes it easier to have a hydrogen fueled boat be attractive and more widely accepted. It will be exciting to have more hydrogen fuel cell vessels because they are quieter, reduce air pollution, and completely prevent polluting fuel spills because hydrogen cannot be trapped by water. It will be a benefit for everyone, everywhere.”

“It’s just not for boats either. Hydrogen filling stations can have these Flow Assist Vent Masts too, as could some vehicles,” Lennie said.

“Add on to that storage facilities for hydrogen, possibly even hydrogen trains that are being considered. This improved vent mast would make all of those hydrogen applications safer,” Myra added.

The Flow Assist Vent Mast is ready for a corporate partner to produce it, and Sandia’s Business Development team is currently promoting the technology. Learn more about transitioning Sandia projects and intellectual property into successful products that benefit the nation.