B61-12 aircraft compatibility certification

Various test activities enabled certification of compatibility for the B61-12 nuclear gravity bomb with multiple aircraft. The F-35A fighter jet, B-2A bomber and F-16A/B fighter all received initial certification, and subsequent releases of the F-15E fighter jet also were certified. (2000, 7000, 8000)

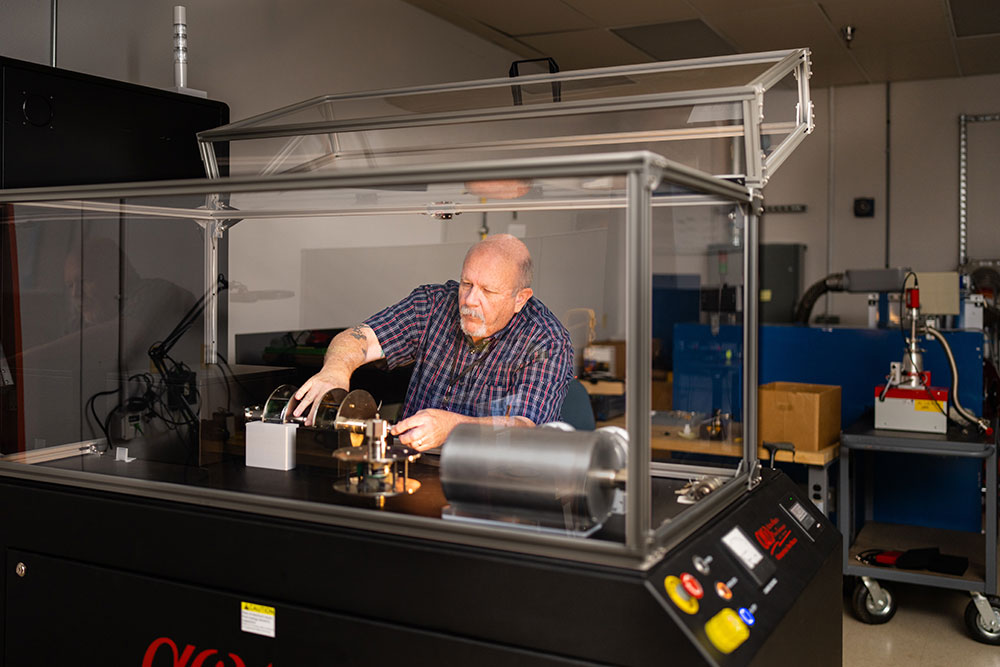

New 10-kiloampere current pulser qualified

The Primary Standards Laboratory Alternating Current Lab procured and qualified a new 10 kA current pulser for pulsed-current calibrations of current-viewing resistors and current-viewing transformers. The lab worked with a commercial company to design and build the system, which was then completed and qualified. The new pulser is completely automated. The Alternating Current Lab created software to automate the system, which reduces calibration time. (2000)

Telemetry team supports stockpile stewardship

The Telemetry Stockpile Support team assisted with the production, assembly and testing of nine different top-level telemetry assembly product lines and associated subcomponents. The effort culminated in 19 surveillance joint test assembly flight tests. (8000)

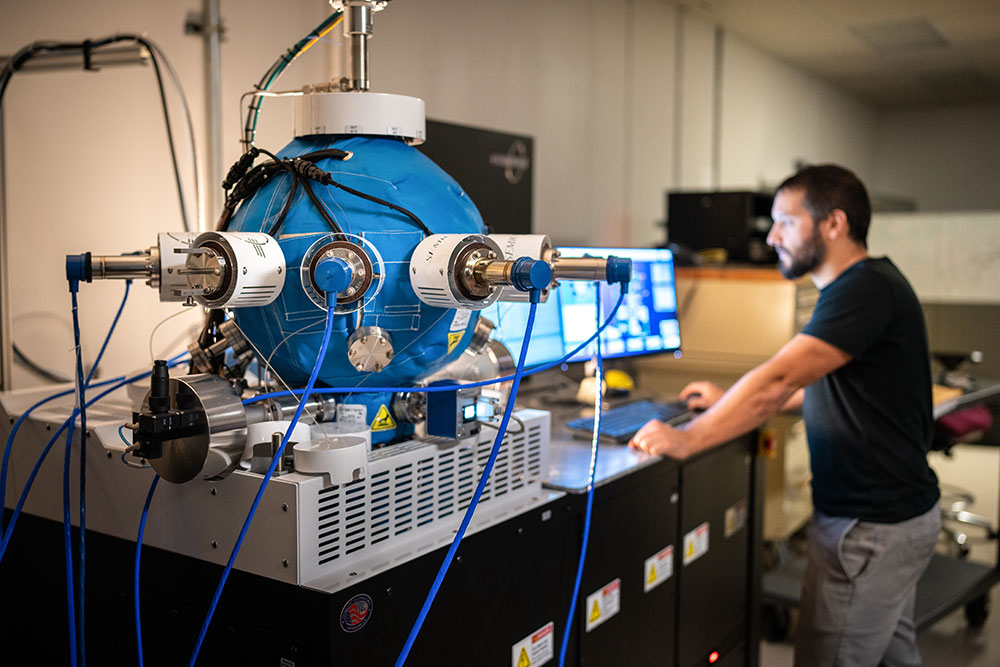

Ultrahigh vacuum measurement system

Sandia’s Primary Standards Lab qualified a new ultrahigh vacuum system that provides more accurate measurements and can calibrate up to eight customer vacuum gauges simultaneously. The system assures accurate measurements at high and ultrahigh vacuum levels (103 to 109 torr). The system qualification enables traceable vacuum gauge calibrations for the nuclear security enterprise. (2000)

Mk21 Fuze ground test success

The W87-0 joint test assembly 4a ground test unit 3B, which serves as a test bed for the Mk21 Fuze, was successfully tested, providing the Mk21 Fuze team with qualification evidence in a realistic environment. Additionally, the two W87-0 System Engineering Joint Test Assembly teams, in coordination with the Telemetry Engineering group, were able to evaluate component performance at the end of the event. The successful execution provided valuable data. (8000)

W80-4 Systems baseline design review

The W80-4 Systems team successfully executed its baseline design review — a major milestone during which an independent panel of experts from Sandia, Lawrence Livermore National Laboratory and Pantex Plant evaluated the completeness and stability of the W80-4 baseline requirements and assessed whether the program is ready to proceed to a final design. The review panel provided positive feedback in numerous areas and said it was impressed by the team’s readiness and engagement leading up to the review. (2000, 8000, LLNL, Pantex)

Warhead options study

The Next Generation Reentry Vehicle 60-day study team, a collaboration between Sandia and Lawrence Livermore National Laboratory, with contributions from NNSA, delivered two reports to NNSA that met all study objectives and timelines. The NGRV team assessed warhead options for postulated future Air Force reentry systems. The study ultimately will affect decisions about the future stockpile.

(2000, 8000, LLNL)

Subcomponent redesign for drop-in replacement

In collaboration with the Kansas City National Security Campus, Sandia modeled, built and tested two new subcomponent designs, showing better performance in manufacturability, safety and robustness. The design intent was to develop drop-in replacements to save production costs. The overall two-year effort spanned the full product lifecycle including prototyping and testing. The work demonstrated the ability to accelerate product realization for new concepts by using such available tools as 3D printing and modeling. (1000, 2000, 7000, KCNSC)

W80-4 teams complete design validation testing

W80-4 Life Extension Program teams completed several major testing accomplishments, including successful execution of the first warhead-level firedown test with electro-explosive devices, the abnormal thermal high-fidelity system test and the abnormal mechanical drop test, as well as the continuation of mechanical environments testing. These tests were the culmination of months or years of effort across multidisciplinary teams, and the results are used to validate designs and further advance development of the warhead. (2000, 8000)

Model-based building predesign

Sandia used a model-based system engineering approach to conceive of and predesign its planned Power Sources facility, significantly improving efficiency, effectiveness and confidence as it transformed mission requirements into capabilities and facility design requirements. The approach provides high confidence that the building is designed to ensure the infrastructure, tooling and facility space necessary to execute mission work. (4000, 7000)

B83 disassembly activities resume at Pantex

The B83 team resumed nuclear explosive assessment operations at the Pantex Plant, following a three-year hiatus. The team succeeded in developing, qualifying and implementing controls and process improvements. This effort required readiness assessments, numerous nuclear explosive safety study activities and countless on-site evaluations. (8000, Pantex)

Air Force NNSA demonstrator program

The Air Force NNSA Demonstrator Initiative is a system-level technology maturation demonstrator program that for the first time integrated early development activities with a delivery platform to show tangible results on the highest priority interfaces. The technologies matured and knowledge gained through the initiative, a collaboration between Sandia, Lawrence Livermore National Laboratory, Lockheed Martin Corp., the Air Force and NNSA, helps position the partnership to respond to future national security needs. (2000, 7000, 8000, LLNL)

Neutron generator team makes specialized part

To meet an urgent need when a supplier went out of business, the Neutron Generator Enterprise established in-house manufacturing for a tight-tolerance metal part that required state-of-the-art, femtosecond laser technology. The team overcame this requirement and other significant supply chain issues to meet the Labs’ commitments for neutron generator deliveries in support of the nation’s nuclear

deterrent. (7000)

Mk21 Fuze program achieves flight test milestone

The Mk21 Fuze program’s flight test unit 3 was launched from Vandenberg Space Force Base

on Aug. 16. The Minuteman III missile flight carried a production pedigree fuze and development telemetry assembled at Sandia/California, directly supporting Mk21 Modification Fuze qualification. Nominal flight trajectory was achieved, and review of the telemetry data indicated successful

performance of the fuze and telemetry system. (1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000, 10000)

B61-12 accepted for production

The B61-12 program produced the first completely refurbished bomb in November 2021. Three months later, the program completed a qualification design review based in part on the final weapon development report. Meeting these milestones resulted in authorization for the B61-12 as a standard stockpile weapon accepted for full-rate production on June 29. (1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000, 10000)

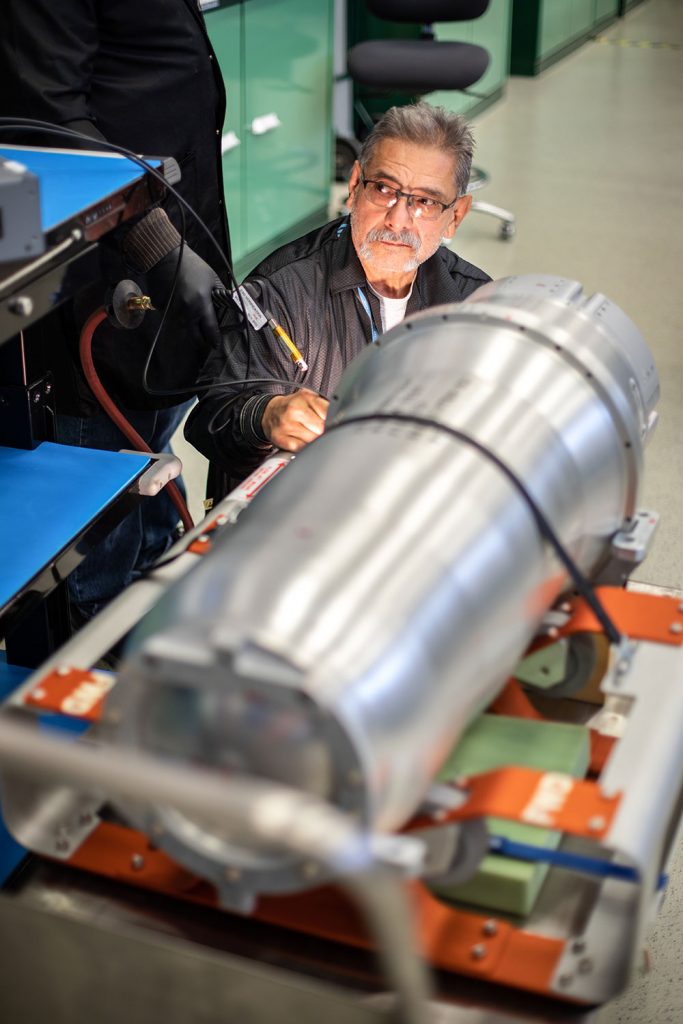

Integrated stockpile evaluation at WETL

Sandia’s Weapons Evaluation Test Laboratory in Amarillo, Texas, completed more than 1,400 tests, including a revival of B83 system testing and the integration of a new Mk21 Fuze tester. Sandia supported more than 15 flight tests and completed 27 component quantification of margins and uncertainties analyses, along with 15 similar analyses for modernization. (2000, 7000, 8000)

Annual stockpile assessment

Sandia completed the annual assessment detailing the safety, reliability and performance of all Sandia elements of the U.S. nuclear stockpile. The process involves internal and external expert reviews of each weapon system and culminates in a letter delivered to the DOE and DOD secretaries and the chair of the Nuclear Weapons Council. This assessment is a key part of the annual report to the U.S. president on the overall condition of the nation’s nuclear stockpile. (2000, 6000, 7000, 8000)

Military Liaison stockpile support

Sandia’s Military Liaison serves as the lead operational interface agent for NNSA and DOD supporting the stockpile and future weapon systems. During its 75th year, Military Liaison provided responses to resolve 775 anomalies related to war-reserve weapons, trainers and ancillary gear in the field. Military Liaison personnel wrote 4,186 pages of technical procedures to support weapons maintenance and conducted 137 weapon training classes for the nuclear security enterprise and DOD. Military Liaison was instrumental in fielding the Code Management System, Disable Management System and the B61-12 bomb. (7000)

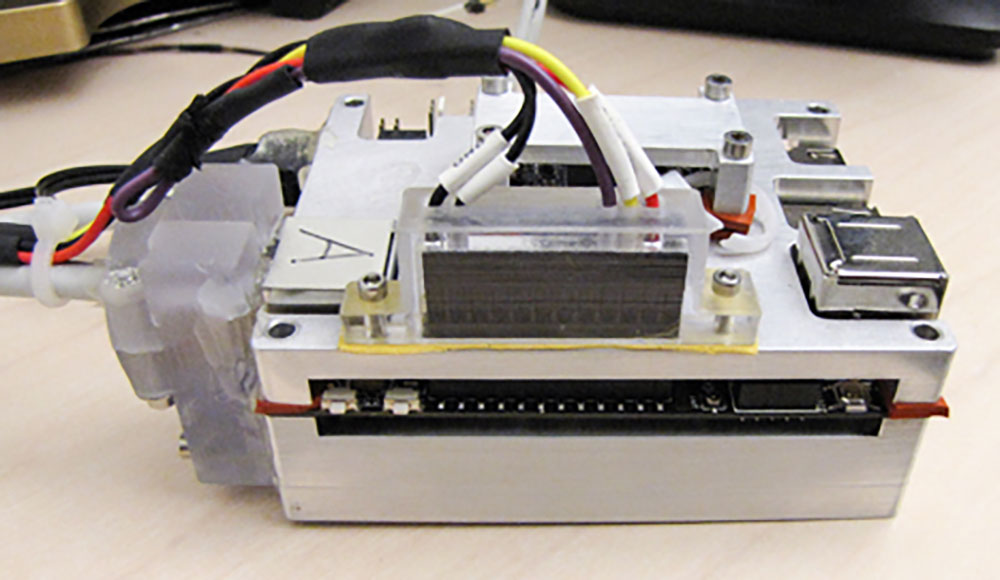

New telemetry transmitter

The High Efficiency Adaptable Telemetry Transmitter is a single-transmitter design that can replace more than 30 individual designs currently flown in joint test assemblies. The HEATT team successfully achieved qualification evaluation release and the first production unit, giving nuclear deterrence programs a common component to meet telemetry needs. The team collaborated with colleagues at the Kansas City National Security Campus to develop creative solutions to complex technical challenges. (2000, 7000, 8000, KCNSC)

W87-1 Phase 6.2A activities completed

The W87-1 team successfully completed and received NNSA approval for the site Weapon Design and Cost Report, meeting a major milestone. The team implemented lessons learned and staffed the program to meet many critical deliverables, including requirements burn-down plans, resource-loaded schedules and uncertainty analyses, joint DOD and NNSA Phase 6.2/2A reports, product definition supporting W87-1 digital engineering strategy goals and execution of an early Nuclear Explosives Safety review. The program now enters Phase 6.3. (1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000, 10000)

Fielding the W88 ALT 370

In January, the W88 Alteration 370 system reached a significant initial operating milestone. The system was delivered to the Navy on schedule, and assessment results were included in the annual report. A successful design review and acceptance group led to acceptance of the W88 ALT 370 as a standard stockpile item. These achievements underpin and strengthen the nation’s nuclear deterrent. (2000, 5000, 7000)

First powered flight for W80-4

The W80-4 Systems team successfully completed the program’s first-powered flight test onboard a development version of the U.S. Air Force’s long-range stand off missile. This major milestone validated the interface between the W80-4 warhead and the missile and provided substantial data to refine the warhead requirements and stockpile-to-target sequence. It also underscored the importance of Sandia’s partnerships with the Air Force, Raytheon Technologies Corp., Kansas City National Security Campus, Lawrence Livermore National Laboratory and other nuclear security enterprise partners. (2000, 8000, KCNSC, LLNL)

Schedule realignment approved for W80-4 Program

The W80-4 program realigned its baseline schedule to better manage risk and more seamlessly integrate with the Air Force’s schedule for long-range stand off missile development. Determining the most effective schedule alignment required a significant effort by multiple teams across the program over nearly two years and was conducted concurrently with the design engineering phase. The proposed realignment was unanimously approved by the Nuclear Weapons Council in June. (2000, 8000)

3D printing of cable

The Production Integration Engineering team produced a functional, 3D-printed rigid flex cable. PIE team and Advanced Materials Laboratory engineers teamed to deploy the printer for on-site printed electronics prototyping. Jointly developing this capability contributes to the team’s mission of producing quality cables quickly and efficiently in support of the nuclear deterrence mission. (1000, 7000)

Electronic Parts Program

Sandia’s Electronic Parts Program implemented a front-end assurance approach, ensuring the program has the required data to assert a commercial electronic part is appropriate for use in nuclear deterrence systems. The W87-1 program is implementing elements of this approach, including a Program Approved Parts List, to select commercial electronic parts that have an existing technical basis in relevant environments. This reduces technical risk and accrual of technical debt by the W87-1 program. (7000)

Characterizing LTC battery cells

Using techniques from its Lithium Battery Laboratory Directed Research and Development Grand Challenge effort, Sandia established a baseline characterization of lithium-thionyl chloride cells for future aging studies. This included novel nondestructive characterization of self-discharge mechanisms, computed tomography scanning and cell disassembly procedures to verify material integrity. The study confirmed known information about cell behavior under discharge conditions and provided a solid technical basis for future aging studies. (1000, 2000, 7000, LDRD)

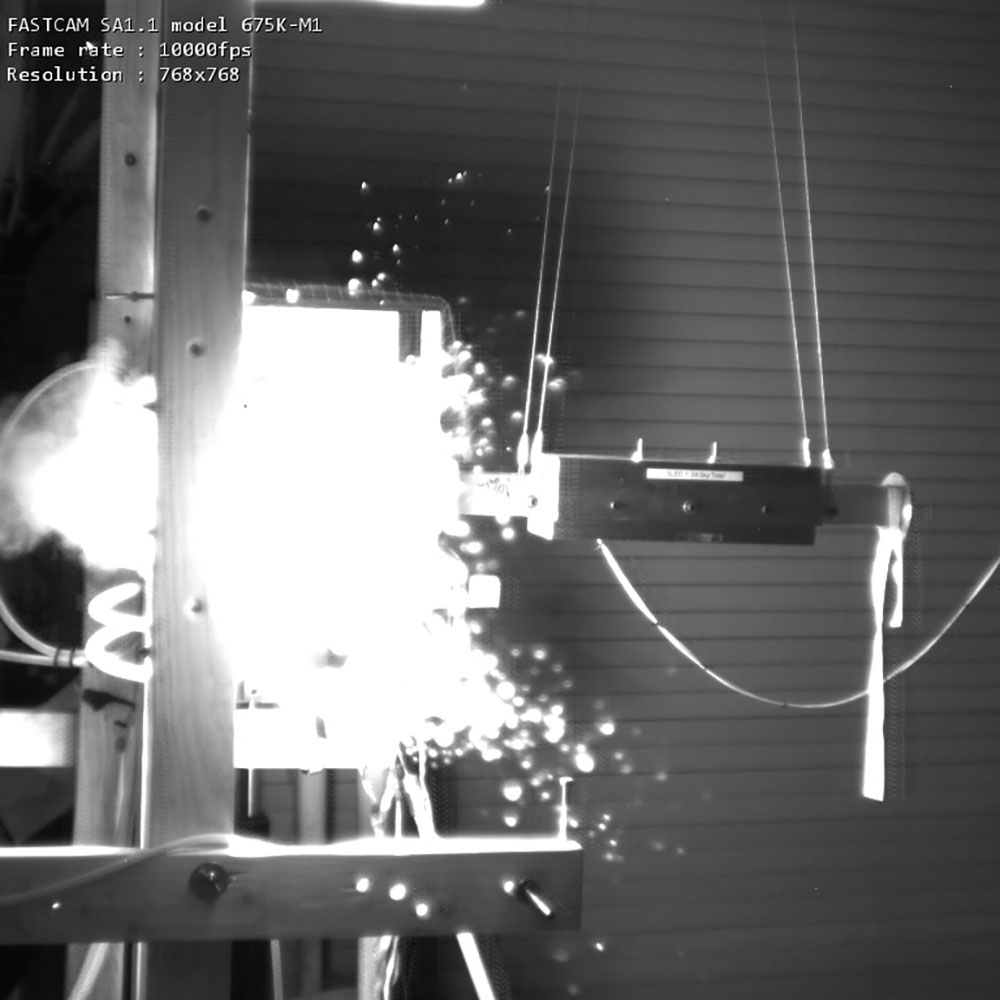

100th Light Initiated High Explosive facility test

The Light Initiated High Explosive facility successfully conducted its 100th test since reopening two decades ago. Building upon the legacy of the facility, which operated from about 1970 until 1992 and reopened in 2002, the test demonstrated LIHE’s enduring contribution to the nuclear weapons enterprise. An LIHE test uses explosive techniques to impart mechanical shocks into reentry systems for qualification, model validation and surveillance activities. (7000)

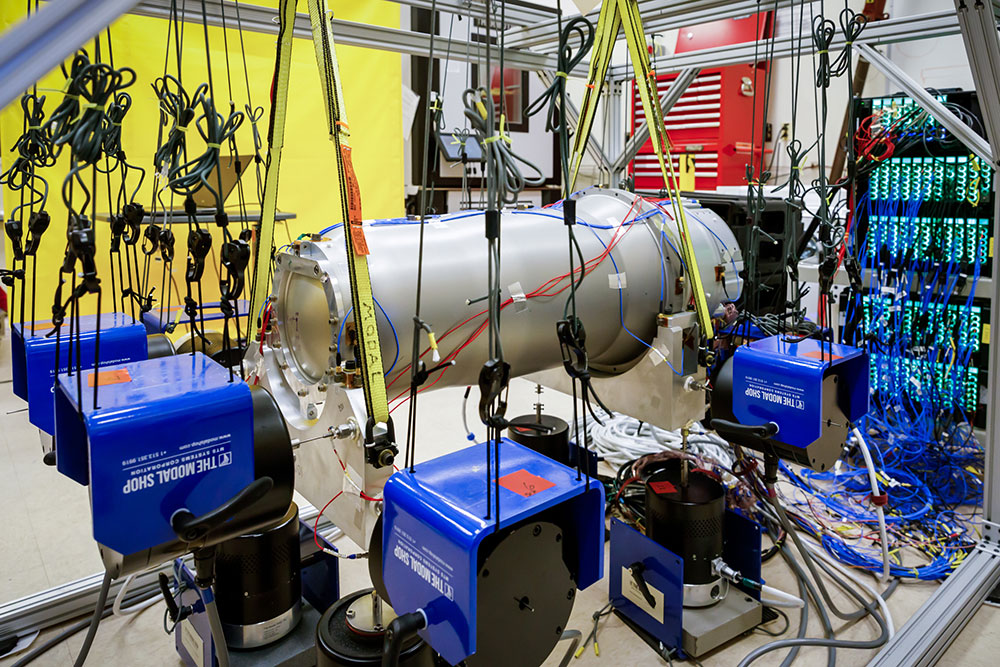

Harsh environment diagnostic capabilities

Nuclear Deterrence teams made advances in determining how safety-critical environmental sensing devices behave in harsh environments. Ultrasonic transducers captured internal device motions during a rocket launch and compared them to centrifuge tests to validate device testing methodologies and computational models. In addition, improved high-speed X-rays visualized the internal dynamic response of the devices during a harsh shock. Both capabilities help Sandia ensure the U.S. nuclear deterrent is safe and reliable. (1000, 7000)

Digital engineering advances

Furthering the Labs’ commitment to digital engineering, Sandia and Kansas City National Security Campus teams implemented major advances in support of nuclear deterrence. Multiple W87-1 product realization teams began using model-based definition and model-based systems engineering for early development activities. Teams also successfully deployed a classified instance of a digital engineering integration platform that allows interoperability among multidiscipline, model-based engineering tools to accelerate design. These improvements lead to robust system architectures, more agile design iterations with production agencies and accelerated product realization. (2000, 7000, 8000, 9000, KCNSC)

Novel 3D-printed packaging solution

Sandia designed, printed, installed and environmentally tested 3D-printed shock and vibration attenuating cushions. To print the Sandia-designed components, staff developed SliceWrite, a transformative Direct Ink Write design utility supporting complex product realization. Testing of geometrically complex silicone hardware demonstrated and proved the feasibility of a novel safety device and electronics packaging solution for nuclear deterrence, improving the producibility of modernization components while enabling rework, reuse and enhanced surveillance. (1000, 7000)