Concentrating solar thermal power and nuclear industries may soon have a safe, reliable, radiation-free environment to test components in flowing, molten nitrate salts. The DOE Solar Energy Technologies Office awarded $2.5 million in funding to Sandia to restart the Molten Salt Test Loop facility at the National Solar Thermal Test Facility. With this funding, Sandia can complete the second phase of the Molten Salt Test Loop Restart project, reopening a test location for researchers and industry partners to study molten salt component systems and salt chemistry compositions.

“Private companies, including many small businesses and startups, have been working to commercialize molten salt systems for concentrating solar power, nuclear energy, fossil energy and other high-temperature industrial process heat applications. A MSTL restart would allow us to set up streamlined agreements so that interested companies could test their components and concepts at the NSTTF, and keep the facility operating,” said Ken Armijo, Sandia solar researcher and the project lead. “By restarting MSTL, we’ll be able to provide real-world test conditions for industry and develop a sustainable path forward for the facility’s future.”

Once in operation, the Molten Salt Test Loop could perform industrial-scale validation and demonstration tests for the concentrating solar power and nuclear industries, contributing to ongoing research in these areas. The facility could also perform contingency scenarios such as rapid shutdown processes and safety procedures. These types of interactions are critical to improve industry safety by addressing accident scenarios such as a heat exchanger failure.

The facility could test high-temperature molten salt pumps, pressure transducers, flowmeters, valves and heat exchangers. In addition to testing concentrating solar power molten salt test components and integrated systems, the facility supports a two-pronged process for researching molten salt reactors. Through this process, fundamental science researchers could address thermodynamic challenges that exist with fluoride salts and perform scoping to determine which materials could be used to replace potentially problematic components. The Molten Salt Test Loop operates at temperatures of up to 600 degrees Celsius, as required for many industrial power and process heat systems.

Additionally, testing at the facility could address knowledge gaps that persist in understanding nitrate molten salts and engineering systems — gaps that may currently prevent small businesses or startups from receiving the licensing they need. At Sandia, this testing can be performed at lab-scale in parallel with a small business or startup, where real power-plant conditions could help certify components for companies seeking molten salt reactor licensing.

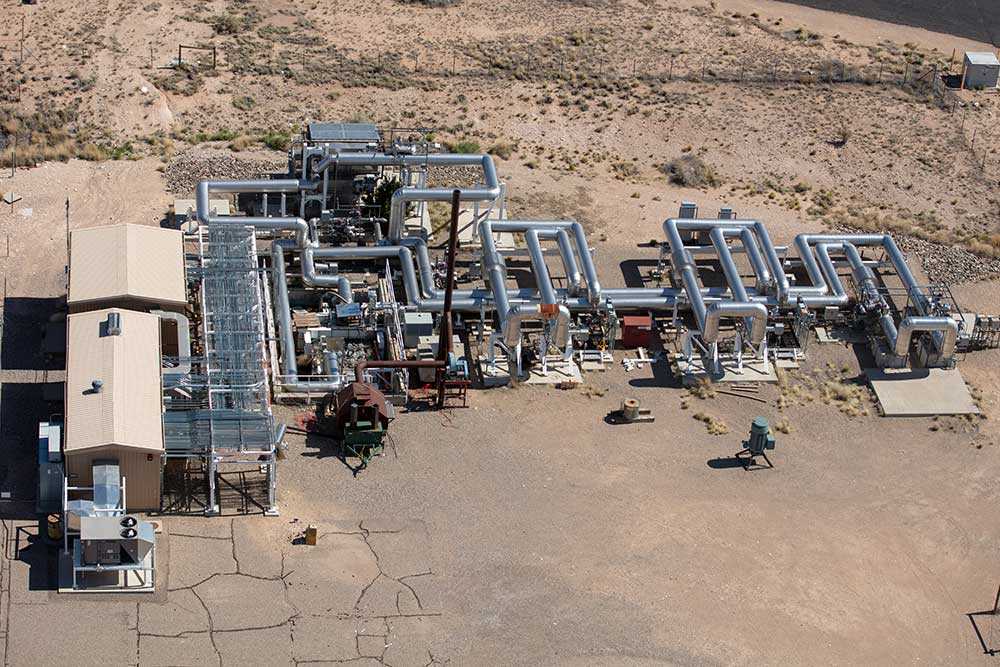

The Molten Salt Test Loop was built and commissioned in 2012 and is considered the world’s largest test facility for molten salts used in concentrating solar power. It features a 7,000-plus-gallon tank, 6-inch schedule 80 piping, and a 600-gallons-per-minute pump. When it opened, it held great promise for special component and specialized system testing. Multiple companies used the facility, and in 2017, a storm caused a power outage that took out the facility’s heating system.

The system was on standby, and the salt was contained in the singular system furnace, where it froze. Although the system remained frozen for several years, a forensics assessment was completed last year to inform the final refurbishments and upgrades costs to revitalize the facility. The team plans to complete the restart by 2026.

Learn more about Sandia’s concentrating solar thermal power research and capabilities.