Creating clean room technology

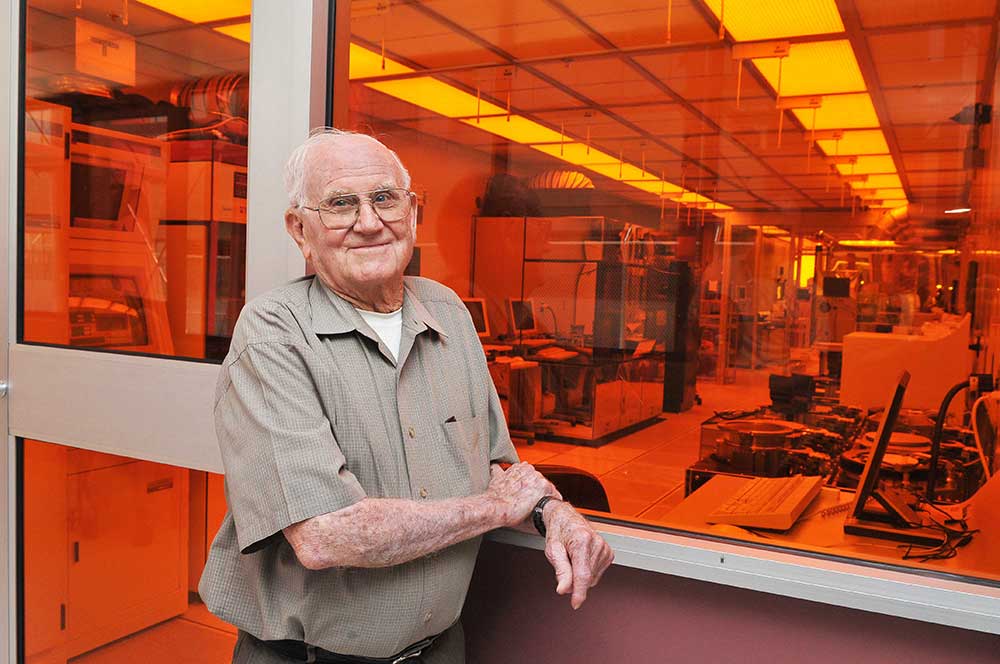

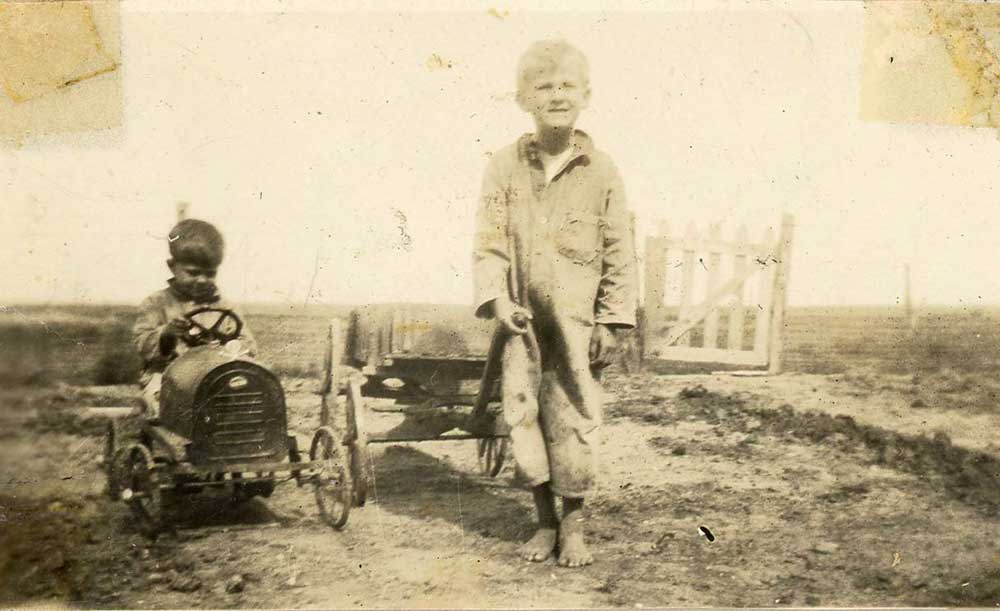

Willis Whitfield was, by all accounts, a simple and humble man. Raised on a cotton farm in West Texas, he knew how to work hard and solve problems, from fixing tractors and other machinery, to inventing equipment when he couldn’t find something that fit his needs. That ingenuity led Whitfield, a longtime physicist at Sandia, to create advanced clean room technology that is still in use today.

The problem at hand

In 1959, there was a common problem affecting the manufacturing of complex parts, including nuclear weapons components. They didn’t work because there were particulates in them. Because Sandia needed the parts for weapons going into the stockpile, and its mission includes pushing the boundaries of science, engineering and technology, it set out to solve the problem. First, the Labs assembled a team from the advanced manufacturing section, which included Whitfield, to look at the issue.

An idea sketched out on a tablet

The team spent the next few months traveling to various manufacturers to see the problem firsthand, along with the clean rooms they had at the time. Those clean rooms were not so clean. Tests showed one of the best clean rooms of the period averaged more than a million particles per cubic foot of air.

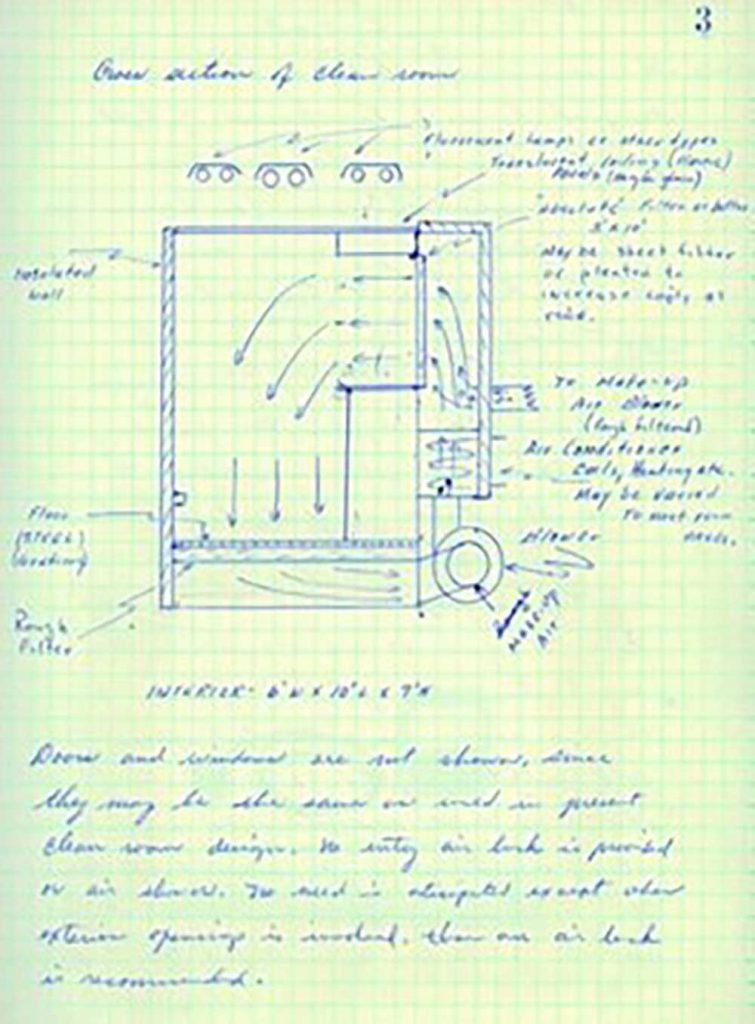

On the way home from one of those trips, Whitfield had an idea. “He was on an airplane, and he whipped out a tablet and basically drew out the whole schematic of how the clean room should work,” said Whitfield’s son Jim, who was 6 years old at the time. “It was just a simple sketch. It just took a few minutes, and it’s the basic principle that is still used today.”

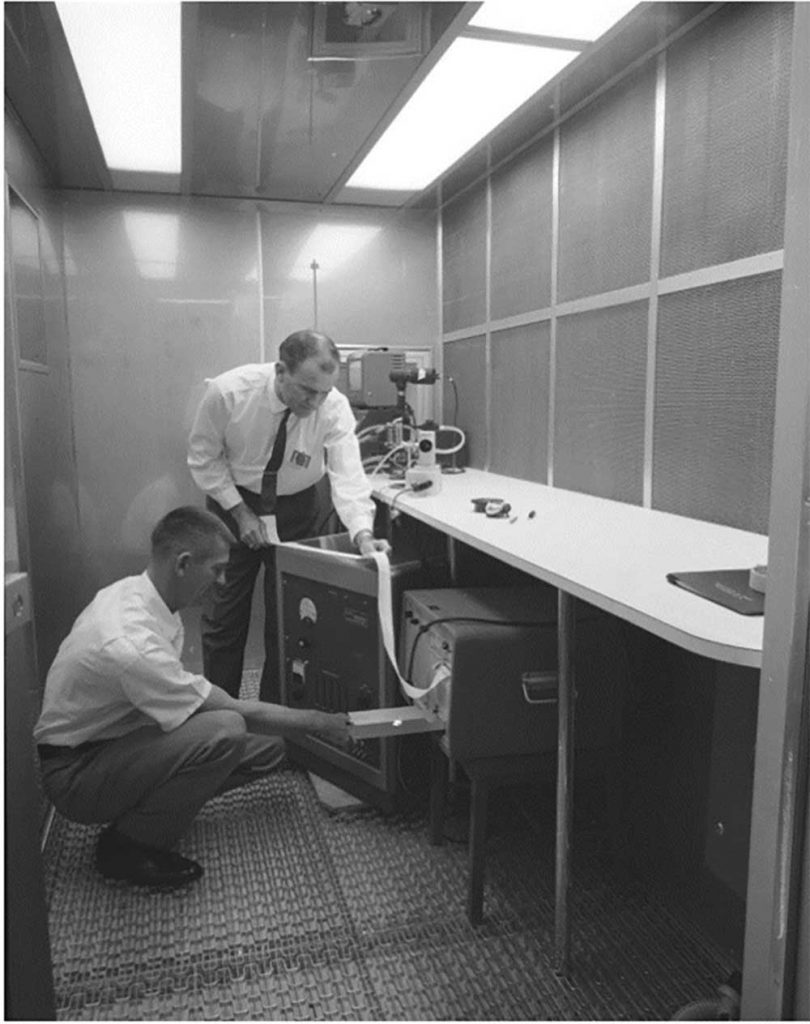

That principle is called laminar-flow, or the constant sweeping of a room with highly filtered air. As Whitfield once said, “It’s letting the air be the janitor.” The process involves pushing particles to the floor, filtering them and circulating them back into the room with a constant but very slow movement of air. Data collected on Whitfield’s 1961 prototype showed an average of 750 dust particles per cubic foot of air — 1,000 times cleaner than clean rooms in use at the time.

It was so clean that some doubted Whitfield’s data was correct.

“People at meetings questioned the claims. There were people there who had to vouch for Whitfield’s credibility,” Sandia historian Rebecca Ullrich said. “When they realized it was real, the idea took off like wildfire. By the mid-1960s, there were standards in place and a variety of different industries picked up the design. It was Sandia’s earliest tech transfer. It was transformative.”

The Atomic Energy Commission filed a patent application on the laminar airflow clean room in Whitfield’s name. On Nov. 24, 1964, the U.S. issued Patent No. 3,158,457, titled Ultra Clean Room.

Clean rooms based on Whitfield’s concept are still used today in everything from electronics and pharmaceutical manufacturing, to operating and recovery rooms to prevent infection. Early adopters included RCA Corp., General Motors Co., Western Electric Co., Bell Laboratories and Lovelace Medical Centers.

A humble man

While Whitfield became known as one of Sandia’s landmark innovators, he always remained humble.

“I do know that one of the things he was always insistent about was mentioning the other people involved. He always gave credit to everyone. While the basic idea was his, he always talked about the team that helped design, develop and test the concept,” Rebecca said. The team included Claude Marsh, James McDowell, James Mashburn, William Neitzel, Irving Kodel, Longinos Trujillo and Harold Baxter.

Whitfield’s son says he was so little when his dad invented the clean room that he didn’t quite understand what he had accomplished.

“The only thing I can remember was one day my dad coming home and telling my mother, ‘We got a raise,’” he said. “At the time, this 6-year-old heard the word ‘raisin,’ and I didn’t quite understand why they were getting so happy about a breakfast food.”

Whitfield said as he got older, he got to see firsthand the impact his dad made.

“He could take very complicated things and just take it down to the essentials. Being an old farm boy, he would just invent something that did an effective job. Even as a kid, a young man, he was that way,” Whitfield said.

Jim Whitfield followed in his father’s footsteps, studying physics, mathematics and electrical engineering. He went on to work for Motorola for 25 years, where he saw a clean room in action. “I actually spent quite a bit of time in my dad’s invention. From a personal point of view, I would say to myself ‘I am working in something my dad made.’ Every time I would walk in, I would say, ‘Thanks Dad.’”

Whitfield’s other work

Willis Whitfield worked at Sandia for 30 years. While creating the modern-day clean room was undoubtedly his biggest accomplishment, Whitfield also did other important work, such as eradicating sewage by turning it into clean water.

“The process didn’t gain huge traction outside of the Labs, but it is early exploration in energy work and solar, which Sandia still focuses on today. It’s part of the work Whitfield invented and participated in,” Rebecca said.

Later in his career, Whitfield helped NASA develop techniques to sterilize spacecraft before missions.

Honoring a legend

Whitfield died in 2012 at the age of 92, just after his clean room invention marked its 50th anniversary. Two years later, in 2014, Whitfield was inducted into the National Inventors Hall of Fame, an honor he shares with people like Eli Whitney, Thomas Edison, Orville and Wilbur Wright, Albert Einstein and more recently, Steve Jobs and John Harvey Kellogg. Whitfield is the only Sandian to this day to be honored with a full-sized bronze statue. It sits outside Sandia’s Microsystems Engineering, Science and Applications complex where clean rooms are used to manufacture precision mechanical assemblies.