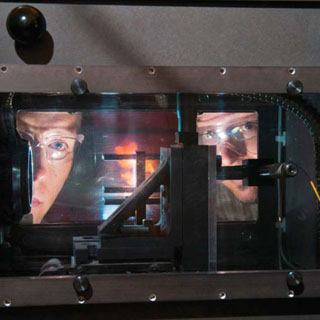

NOT SO BIG BANG — Alex Tappan (left) and Rob Knepper (both 2554) watch the detonation of a Sandia critical thickness experiment. The experiment typically uses less explosive material than the size of one-tenth of an aspirin tablet to determine small-scale detonation properties. The bench-top experiment is so small, researchers can stand next to the firing chamber with eye and ear protection. (Photo by Randy Montoya)

The explosive PETN (pentaerythritol tetranitrate) has been around for a century and is used by everyone from miners to the military, but it took new research by Sandia to begin to discover key mechanisms behind what causes it to fail at very small scales.

“Despite the fact explosives are in widespread use, there’s still a lot to learn about how detonation begins, and what properties of the explosive define the key detonation phenomena,” says Alex Tappan (2554), who has been with Sandia for 14 years, all of it in the Explosives Technology Group.

Explosives are typically studied by pressing powders into pellets; tests are then done to determine bulk properties. To create precise samples to characterize PETN at the mesoscale, the researchers developed a novel technique based on physical vapor deposition to create samples with varying thicknesses. That allowed them to study detonation behavior at the sub-millimeter scale and to determine that PETN detonation fails at a thickness roughly the width of a human hair. This provided a clue into what physical processes at the sub-millimeter level might dominate the performance of PETN.

Years of work went into the process, says Alex.

The idea is that by understanding the fundamental physical behavior of an explosive and the detonation process, researchers will be able to improve predictive models of how explosives will behave under a variety of conditions.

Getting a handle on the variables

Right now, “if we want to model the performance of an explosive, it requires parameters determined from experiments under a particular set of test conditions. If you change any of the conditions, those models we have for predictions don’t hold up any more,” says Rob Knepper (2554).

Physical vapor deposition works like this: Researchers put PETN powder in a crucible inside a vacuum chamber and heat it so the PETN sublimes or evaporates. Above the crucible is a flat substrate of plastic, ceramic, or metal, and the PETN vapor deposits on that, producing explosive films.

Such pristine samples allow the team to study the initiation and detonation behavior of explosives, Alex says.

“By varying deposition conditions, we’re starting to get a handle on how the deposition conditions affect the microstructure and how microstructure affects detonation behavior,” Rob adds.

The tests use less explosive than what’s inside a .22-caliber bullet, and researchers wearing safety glasses and ear protection can stand next to the experiment in a protective enclosure, Alex says.

“A typical experiment weighs about a tenth of an aspirin tablet,” he says. “If that tablet is 325 milligrams, we’re shooting about 32.5 milligrams. These are not huge.”

The team did multiple shots to determine at what point detonation fails.

“As size [thickness] decreases further and further, at some point the detonation will slow down and eventually fail,” Alex says.

His interest in the subject goes back to when he and his brother as kids fostered each other’s interest in fireworks and explosives. Alex, a chemist, became involved in Sandia’s projects through an interest in collaborations and because of a mentor, Anita Renlund, a senior scientist with the Explosives Technology Group who retired in 2008. Rob, whose background is in materials science, began working for Sandia in 2009 as a postdoctoral appointee working with Alex. Rob later moved to the Labs’ regular staff, continuing on many of the same projects.

Alex, Rob, and co-authors Ryan R. Wixom, Jill C. Miller, Michael P. Marquez, and J. Patrick Ball presented a paper at the 14th International Detonation Symposium in Coeur d’Alene, Idaho, in 2010. They wrote in the paper, “Critical Thickness Measurements in Vapor-Deposited Pentaerythritol Tetranitrate Films,” that the work represented the first highly resolved measurements of detonation failure in high-density PETN.

Work began as an LDRD project

It adds new information for a very old explosive.

“What we brought to the table is a new experiment that allowed samples to be made that are small enough to measure this critical thickness property,” Alex says. “Other research has been done on PETN in a different form or when it had a binder added to it. This is the first time these data have been done on the critical detonation geometry for pure, high-density PETN.”

In the past, diameter information was obtained through experiments using high-aspect-ratio cylinders of pressed pellets of differing diameters. But it’s difficult to press pellets with diameters smaller than 1 to 2 mm with precise density.

The work began under a three-year Laboratory Directed Research and Development project that ended in 2001. It’s now funded largely through a combination of internal and external programs.

The research falls under the umbrella of Sandia’s Microenergetics Program, which Alex says uses novel techniques to produce small-scale explosive samples to study ignition, combustion, and detonation phenomena. It began as a collaboration among researchers in the Explosives Technology Group 2550, Manufacturing Process Science and Technology Group 1830, Engineering Sciences Center 1500, and Microsystems Science and Technology and Components Center 1700.