While more than half of all cars sold in Europe run on diesel engines, the technology has yet to take hold in the American consumer car market. That could change as the twin pressures of skyrocketing gas prices and increased levels of carbon dioxide emissions are driving major shifts away from the status quo in the automotive industry. Mercedes-Benz, Volkswagen, BMW, and Honda are among car companies that plan to release diesel engine models in the US in the near future.

Diesel engines have several advantages over gas-powered engines: They burn less fuel, have better drivability, and last longer. Even with higher diesel fuel costs, drivers will still get more bang for the buck from a diesel engine. Diesels, unfortunately, have a reputation for being loud, smelly, and smoky, but a new generation of clean diesel engines aims to allay those concerns.

These engines often employ low-temperature combustion techniques to reduce nitrogen oxides (NOx) and soot emissions. These techniques, however, can lead to high carbon monoxide (CO) emissions — with concomitant efficiency loss — particularly at light loads. Understanding the detailed sources of CO emissions is critical to minimizing them, but, until now, in-cylinder visualization of these emissions had never been achieved.

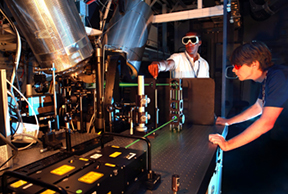

Recently Paul Miles, Will Colban, and Isaac Ekoto (all 8362), along with Duksang Kim, a visiting researcher from Kookmin University, Korea, succeeded in visualizing the CO distribution in an operating diesel engine for the first time using a two-photon laser-induced fluorescence (LIF) technique. The work is funded by DOE’s Energy Efficiency and Renewable Energy (EERE) Office of Vehicle Technologies and General Motors.

“Knowing the sources of combustion inefficiency embodied in carbon monoxide can drive design decisions that will make engines more efficient,” says Paul.

Using LIF to visualize carbon monoxide emissions proved technically challenging. Single photon excitation doesn’t work with CO, since the molecular transitions aren’t accessible with visible wavelengths or near-UV. With single photon LIF, a wide laser beam that comes to a focus within the engine is typically used to avoid damage to the engine windows. The strong signal variation with beam intensity of two-photon LIF means the beam must be nearly the same width as it traverses the engine, which results in a more intense beam going through the windows.

“We used the highest grade of UV fused silica windows and we still only got about 2,000 shots before we damaged the window,” explains Paul. The researchers learned to shoot through only the top of the circular windows, and then rotate them to extend their life.

The testing is done on engines in the Combustion Research Facility that have the same geometry as production engines, down to the details of the piston bowl shape and valve cutouts. Paul says the team carefully characterized the spectral nature of the emissions to be sure they were not getting interference from unburned hydrocarbons.

A major finding was that the squish volume of the engine is a source of emissions. “The squish volume is a feature of the combustion system that is needed for good conventional diesel performance. Our results point to the possibility that different combustion chamber designs could be more appropriate for low temperature combustion systems,” explains Paul.

The results of the project have also enabled validation of numerical simulations on which engines are designed. Paul says that simulations successfully predict trends in emissions, but the details of what is happening in-cylinder, which could lead to optimized geometries, just aren’t well known or accurately predicted.

The Basic Energy Sciences work done on CO fluorescence proved invaluable to the success of this project. “Previous researchers had measured photo-ionization cross-sections, absorption cross-sections, and CO quenching cross-sections with all the major partners as a function of temperature,” says Paul. “It was a godsend to have the fundamental data. It enabled us to come up with semi-quantitative measurements.”

The measurements are expected to help improve the accuracy of the models used for engine design and optimization.

While Paul notes that quantifying what these results could mean, in terms of improved fuel efficiency, is difficult, he does think it could lead to a 4-5 percent increase. “These results will have a direct impact on engine design,” he says. “This research is more closely aligned to the needs of industry than anything else I’ve done at Sandia.”