Geothermal drilling tool can take the heat

Sandia and a commercial firm have designed a drilling tool that will withstand the heat of geothermal drilling.

The downhole hammer attaches to the end of a column of drill pipe and cuts through rock with a rapid hammering action similar to a jackhammer. Downhole hammers are not new — the oil and gas industry and mining have used them since the 1950s — but the older design, with its reliance on oil-based lubricants, plastic, and rubber O-rings, isn’t suited for the hotter temperatures of geothermal drilling.

“The technology behind the new hammer is fundamentally the same, but Sandia worked with a Sweden-based company, Atlas Copco, in material selection and dry lubricant technology that will work in the high-temperature environment,” says mechanical engineer Jiann Su (6916), Sandia’s principal investigator on the project with Atlas Copco, which operates worldwide and makes specialized equipment and systems for drilling, mining, and construction.

DOE’s Geothermal Technology Office funded Atlas Copco as prime contractor on the project, and the company partnered with Sandia as the subcontractor.

“Part of what the DOE’s Geothermal Program is looking to do is help lower the cost of getting geothermal energy out to customers,” says Jiann. “Some of reducing the cost is lowering exploration and development costs, and that’s one of the areas we’re helping to tackle.”

The Geothermal Energy Association’s 2016 annual production report says the US had about 2.7 gigawatts of net geothermal capacity at the end of 2015. In addition, the US market was developing about 1,250 megawatts of geothermal power, and new renewable portfolio standards in states such as California and Hawaii could create opportunities for geothermal energy, the report says.

Jiann says the high-temperature hammer could help reach those development goals.

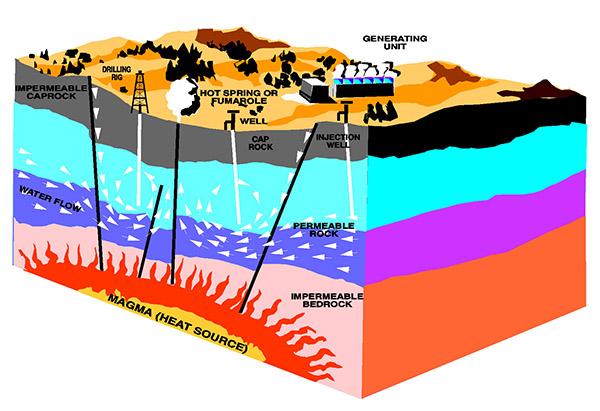

Geothermal energy holds tremendous promise, but drilling down to heat sources in the earth’s magma demands tools able to withstrand ultra-harsh environments.

A plus for drillers

Jiann considers the just-finished three-year project a success, and says the team and Atlas Copco are looking for opportunities to deploy the tool.

“We developed a tool that can be used in high-temperature environments that can help increase the drilling rates and the rate of penetration to maybe 5 to 10 times that of conventional drilling operations, so that’s a big plus for drillers,” he says. “It adds to the available options drillers have. This is not necessarily the final option for every drilling situation but it does provide a good option for the right situation.”

Atlas Copco turned to Sandia for its expertise in materials, understanding about how moving surfaces interact, and high-temperature testing and operations.

“Atlas Copco is the expert at designing and manufacturing the hammers, but Sandia is better equipped to handle the high-temperature challenges, the lubrication, and materials,” Jiann says. “And high-temperature testing isn’t something that Atlas Copco typically does.”

A critical piece of the project was developing lubricious coatings, which help reduce friction between parts, important in geothermal operations. “As temperatures increase, the oils essentially cook and you get this sooty mess inside. It’s like running your car too long without changing your oil,” Jiann says. The hammer has internal moving components that require lubrication, similar to a piston in a car engine.

His team’s work on materials and lubricious coatings built on decades of Sandia research in those areas. The team worked with Sandia’s Materials Science and Engineering Center on a multilayer solid lubricant capable of operating at high temperatures. Similar solid lubricants are used commercially, for example, to improve the lifespan of moving components in cars, but Jiann’s team worked with a formula tailored to the operating conditions and base materials.

“If we were starting from scratch, the difficulty level would have been high, but since Sandia has a history of experience in that arena we had some idea of what to start with,” he says. “It made things a lot easier.”

Development took three years

The project began by determining whether a high-temperature hammer was even possible. The Sandia team initially tested materials and coating combinations that would survive the expected environments while Atlas Copco designed a hammer without plastic parts, Jiann says. They proved the concept, and the project spent the next two years building hammers and a facility for high-temperature testing.

The hammers proved successful. “We were able to reach our drilling rates, the materials held up, the coatings worked well,” Jiann says.

Sandia’s new facility is designed to test hammers under real-world operating conditions, including temperatures up to 572 degrees Fahrenheit (300 degrees C). Conventional drilling generally sees temperatures of less than 320 degrees F (160 degrees C).

The high operating temperature (HOT) test facility, a three-sided open concrete structure, houses a 20-foot-tall drill rig, heating chamber, and process gas heater. Researchers can simulate conditions deep underground and the elevated temperatures affecting the hammer and can drill into different types of rock, like the granite commonly found in geothermal-rich areas. The facility is instrumented to measure drilling parameters.

HOT was in itself a large project. “We took a little more time in the development process but when we put it all together, everything worked pretty much as we expected it to,” Jiann says. The work required integrating multiple subsystems, including electrical, mechanical, pneumatic, and control systems. Sandia also worked with Atlas Copco about what instrumentation was required to collect the necessary data.

“We’re using the facility for other activities that we’re doing now,” such as developing drilling automation, Jiann says. “That’s a plus for Sandia.”

The research team consisted of members of the Geothermal Research Department including Jeff Greving, Dennis King, David Raymond, and Elton Wright. Members from the Materials Mechanics & Tribology included Somuri Prasad and Rand Garfield. Contributions from Robotics Research & Development, including Tim Blada and Ani Mazumdar; Facilities, including Carlos Medrano; and Business Support, including Becky Campbell and Rosemae McKillip, also were critical to the project.