Geometry Power Tools

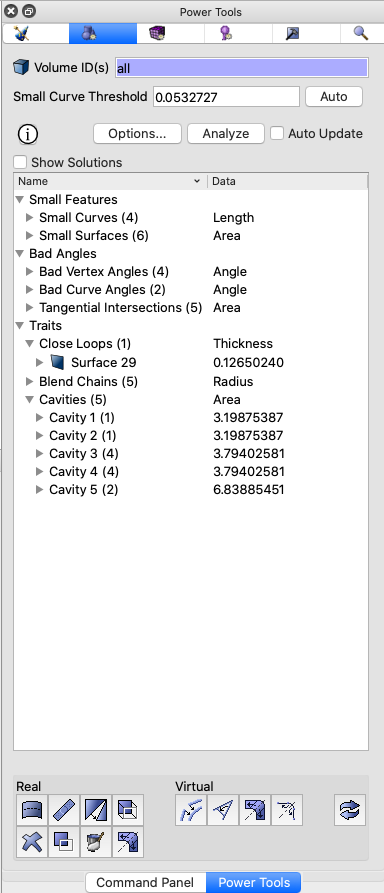

Figure 1. Geometry

power tools panel |

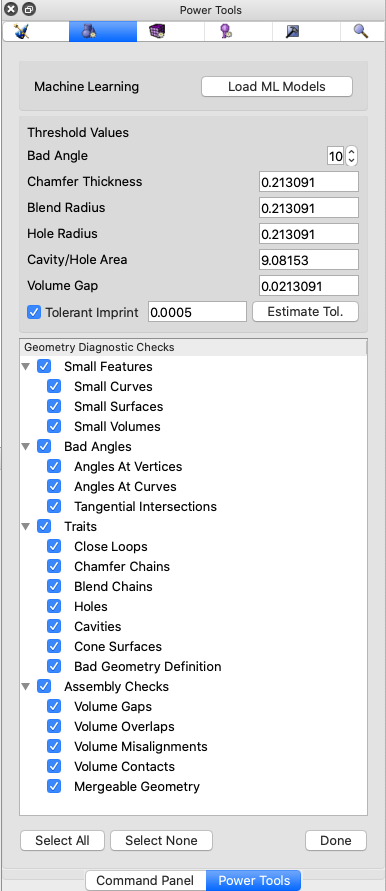

Figure 2. Geometry

power tools options panel |

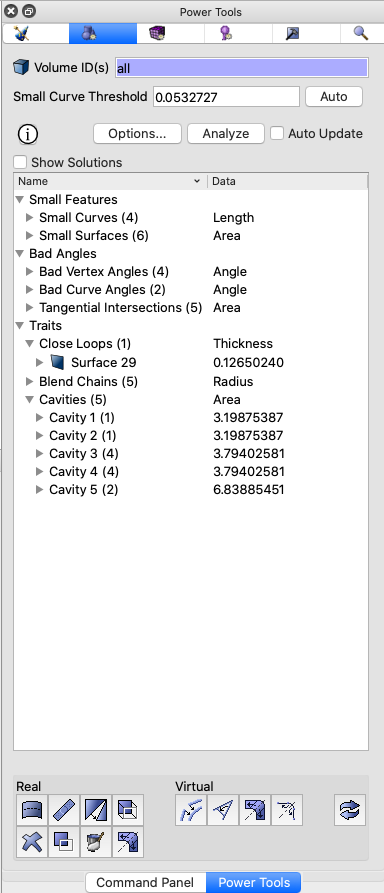

The geometry power tools, shown in Figure 1. are located on the Tree

View window under the blue geometry tab. The Geometry Power Tool provides

several diagnostic tests to identify and repair problems in your CAD model

prior to meshing including machine learning-based

diagnostics and solutions.

Diagnostic tests include:

This tool analyzes geometry for various characteristics

that may affect meshing outcomes and aid in simplification and defeaturing.

It also contains a powerful toolkit of geometry modification methods to

fix these problems. Many of the common geometry clean-up

tools are available from this tool without the need to search through

the command panels for relevant operations.

The geometry power tool includes a window that lists results from geometry

analysis in a tree format. In addition, a solution window can be displayed

that will display specific suggested geometry solutions for the currently

selected entity.

Suggested Usage

The following is a suggested workflow for using the geometry power tool:

- Enter volumes to analyze: Enter or pick the volume

IDs you wish to analyze in the field labeled Volume ID(s).

By default, all volumes will be analyzed. For large or complex assemblies,

consider selecting only a few volumes at a time to avoid long analysis

times.

- Enter a small curve threshold: The value entered

in the field labeled Small Curve Threshold defines

the basis for what is considered "small" for most geometry

tests. If Cubit already has more than one volume defined, a default

value for small curve threshold will be computed as 0.25*mesh_size.

To update the default small curve threshold for the

current volumes, select the Auto button. If no mesh

size is currently defined, an autosize factor of 2.5 will be used

to compute a mesh size. (Equivalent to vol all size auto factor

2.5)

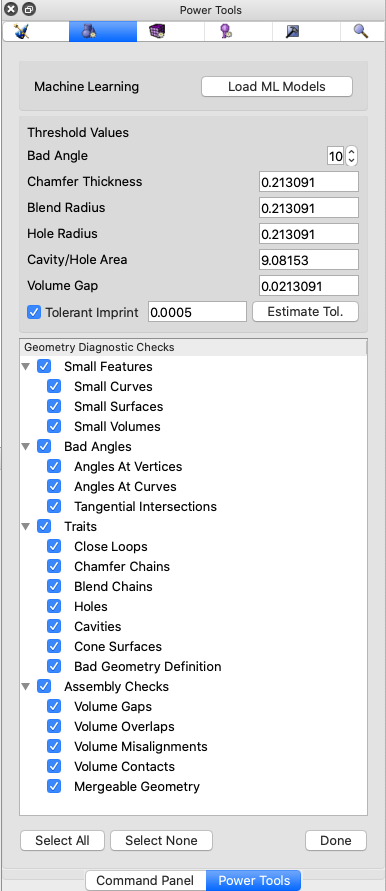

- Select diagnostics to perform: Selecting the Options...

button will display a list of available diagnostics grouped by category,

as shown in Figure 2. By default all diagnostics are selected. Some

diagnostics may not apply to specific geometry, or may only need to

be run once per geometry. To avoid long analysis times, select only

diagnostics that are relevant for your current problem scope. Clicking

on the box by each test will select or deselect it. Categories of

diagnostics may also be selected or deselected in a similar manner.

All diagnostics may be selected or deseleted using the Select

All and Select None buttons at the bottom

of the panel. Threshold values used for some of the diagnostics can

also be entered, including bad angle, chamfer thickness, blend or

hole radius, cavity area and volume gap thresholds. Details on each

of the diagnostics are described below. Select

the Done button to return to the main Geometry power

tool panel.

- Analyze the geometry: Click the Analyze

button to initiate an analysis of the selected diagnostics. The time

taken for analysis will vary based on the number and complexity of

volumes and the diagnostics selected.

- Select an entity to examine: Once analysis is

complete, the results will appear in the main window of the geometry

power tool panel in the form of an expandable lists categorized by

the selected diagnostics. Items in the list correspond to the selected

tests. Expanding a list will display an ordered sub-list of geometry

entities that have been identified by the test. Selecting one or more

entities in one of the lists will also highlight the entities in the

graphics window. Use shift-click or command/ctrl-click to select multiple

entities in the list. Use the context menu (right click) to zoom or

fly in, locate, draw or other methods to graphically examine the selected

entities.

- Choose a geometry repair solution: Multiple methods

are provided for choosing and selecting a relevant geometry repair

solution:

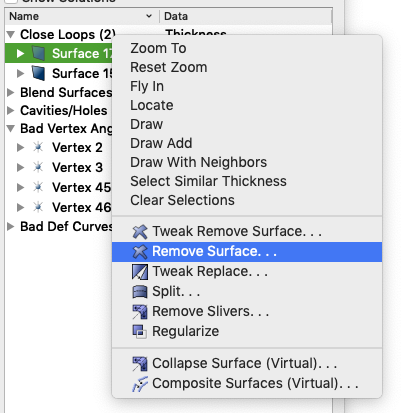

- Context Menu: Right clicking

on an entity in the list will reveal a list of options that are

normally relevant for the selected entity type. (See Figure 3.)

For example, selecting the Remove Surface...

menu item will bring up the Remove Surface command panel pre-populated

with the relevant entity. To execute the same operation on many

entities at once, first select all relevant entities in the list.

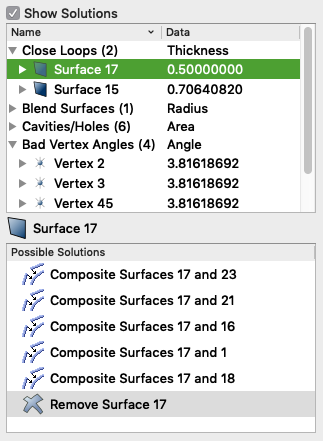

- Show Solutions: Selecting the Show

Solutions check box at the top of the results window

will display an additional window, (See Figure 4.) populated with

relevant operations for the currently selected entity. Selecting

a solution will display a preview of the operation in the graphics

window. Double clicking the solution will execute the solution.

A right click on the solution will show a context menu revealing

the following options:

- Execute: Execute the selected solution

(same as double click).

- Show More Solutions: Add additional solutions

computed for attached entities if they exist. For example,

if a small curve is selected, this option will include additional

solutions in the window for its attached surfaces and vertices.

- Open Command Panel Operation: Depending

on the type of solution selected, the relevant command panel

will appear pre-populated with the options called for in the

solution. This provides the option to further customize the

solution if the precise desired command is not displayed.

- Command Panel Buttons:

The buttons at the bottom of the geometry power tool will display

a specific geometry command panel. This can be useful if many

similar operations are to be performed on different entities.

A description of each is provided below.

Figure 3. Geometry

entity context menu in power tool. |

Figure 4. Entitiy-specific

solutions displayed in geometry power tool. |

Geometry

Analysis Tools

The geometry power tools, contain various

diagnostic tests that can be run on geometry to diagnose potential problems

for mesh generation and defeaturing. To display a list of tests, click

on the Options... button. The panel shown in Figure 2.

will appear. Select or deselect the desired options from the window before

performing an analysis. To avoid long analysis times, select only tests

that are relevant for your current problem scope. Cubit will also save

the current test selections between runs. The geometry analysis tests

are summarized below:

Small features may be necessary and desirable in a model, but many times

they are the result of poor geometry construction, or they may just not

be important to the analysis. The small features tests look for small

curves, small surfaces, and small volumes. These tests rely on the user-defined

small curve threshold value defined at the top of the

Geometry poert tool.

- Small Curves - Small curves, including zero-length

curves such as hardpoints, are compared directly against the small

curve threshold value, and identified if they are less than

or equal to the given value.

- Small Surfaces - Small surfaces are identified

based on area and hydraulic radius. Surface areas that are less than

the square of the current mesh_size are identified

as small. For surfaces where the hydraulic radius, defined as 4*surface_area/perimeter,

is less than the small curve threshold are also identified

as small.

- Small Volumes - Small volumes are identified by

their hydraulic radius, defined as 6*volume/surface_area.

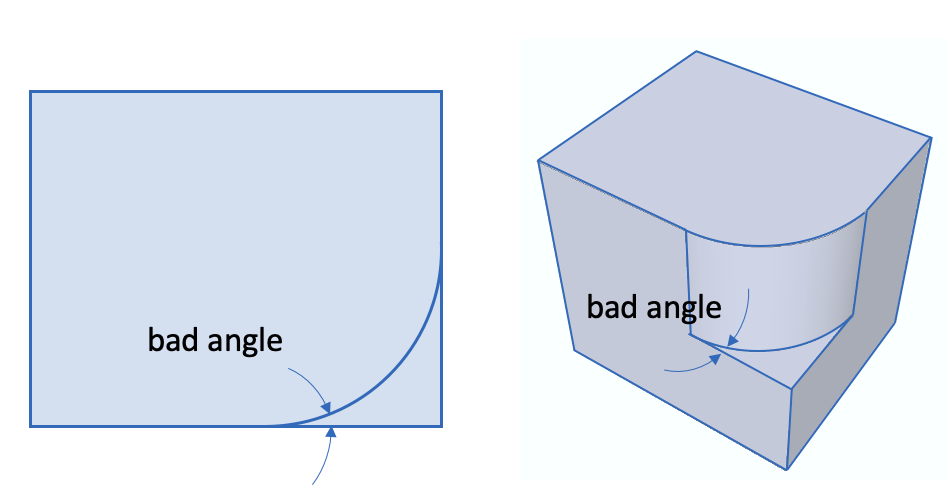

Small geometric angles at vertices and curves can sometimes over-constrain

the resulting mesh resulting in poor element quality. These tests are

controlled by the Bad Angle threshold value defined at

the top of the Geometry power tool Options panel.

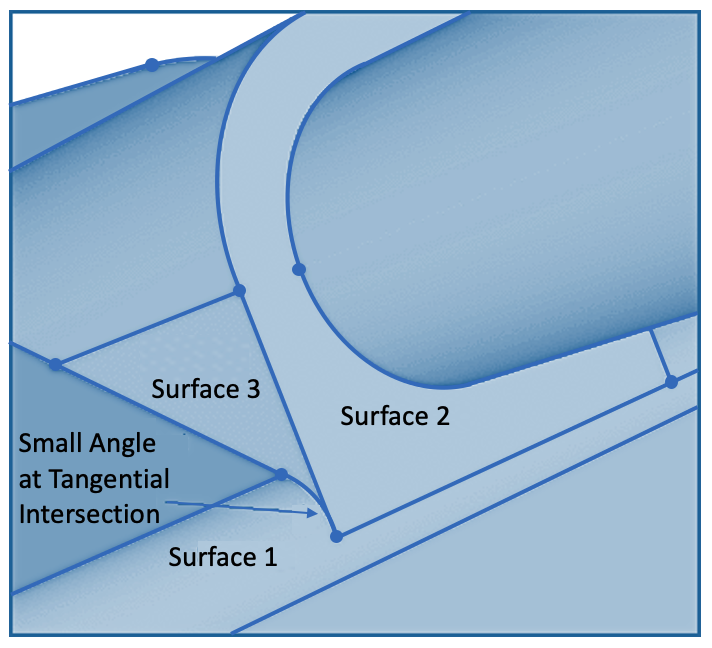

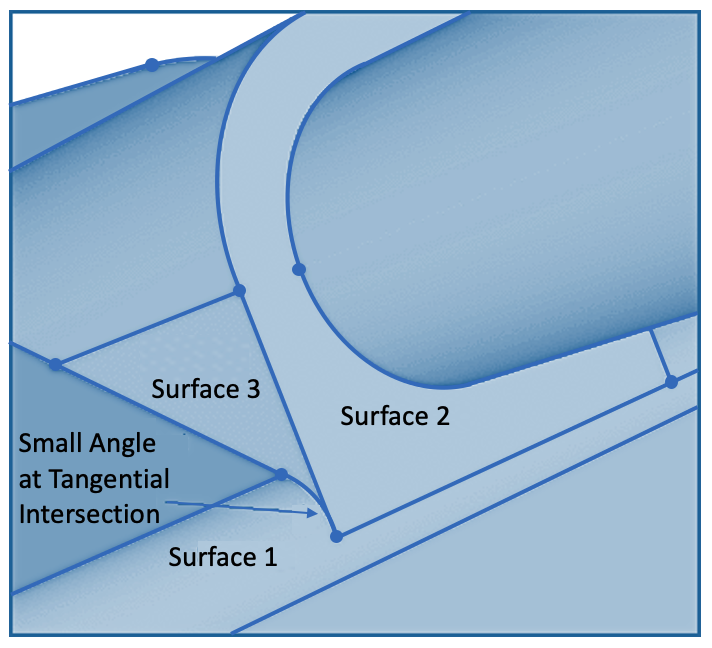

Figure 6. Tangential Intersection

Example

The tests in the Traits category, group entities according

to a specific characteristic of the geometry such as its thickness or

radius. Use the threshold values at the top of the Geometry power tools

Options panel to set limits on values used to control entities returned

from these tests. Geometry Traits include the following:

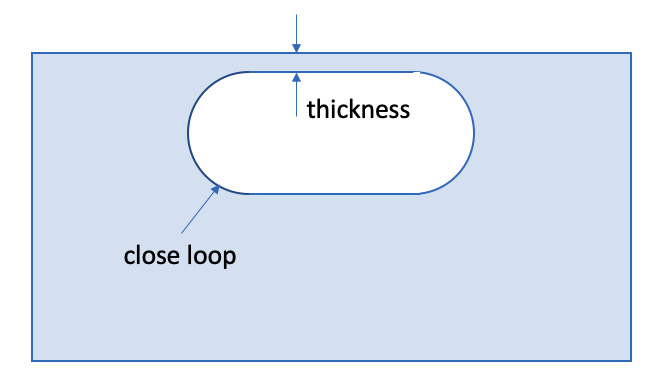

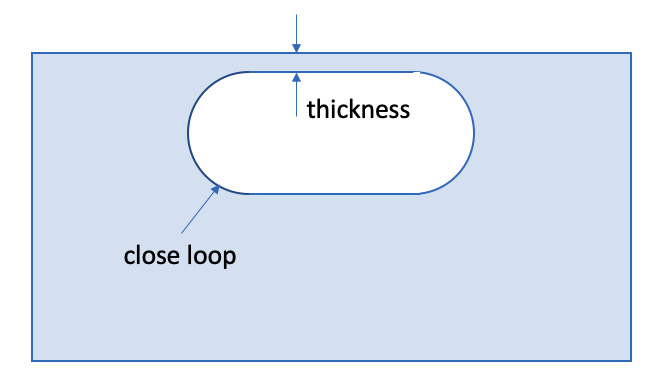

- Close Loops - Close loops are identified by two

curves on a single surface for which the shortest distance between

them is less than the current mesh_size. Surfaces

identified as close loops are ordered based on the minimum thickness

of the surface between the loops. These surfaces and their immediate

neighbors are often candidates for the remove

surface command.

Figure 7. Close Loop

Example

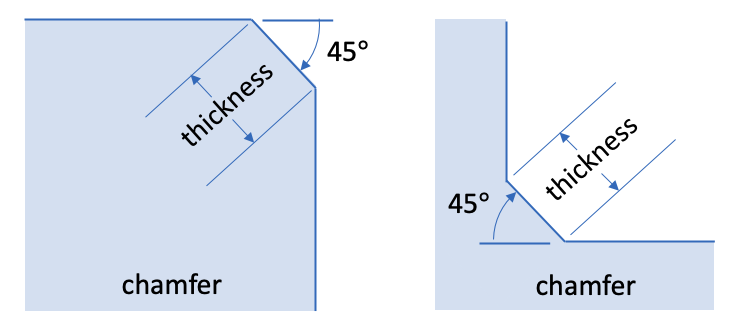

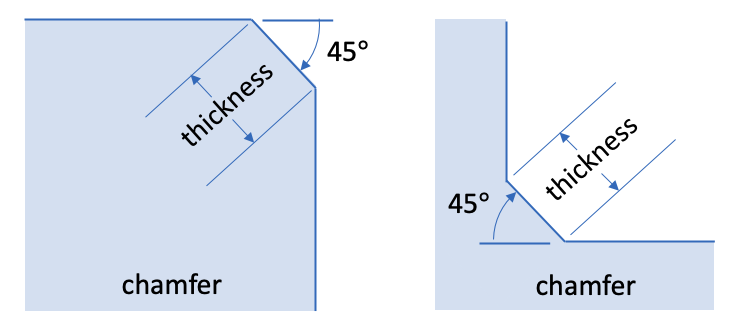

- Chamfer Chains - A chamfer surface can be identified

as a narrow strip where its angle to neighboring surfaces is about

45 degrees as shown in Figure 7. Chamfers often occur as a chain or

connected set of surfaces and are grouped together in the power tool

as a collection of surfaces that can be expanded and examined individually.

Chamfer chains are ordered based on the narrow thickness of the surfaces

illustrated in Figure 8. Setting the Chamfer Thickness

threshold in the Options panel will control which chamfer chains will

be identified. The default value for Chamfer Thickness

threshold is the current mesh_size Since chamfers

with small thickness can effect the resulting size of the elements

the remove

surface option is often used to eliminate them.

Figure 8. Chamfer Examples

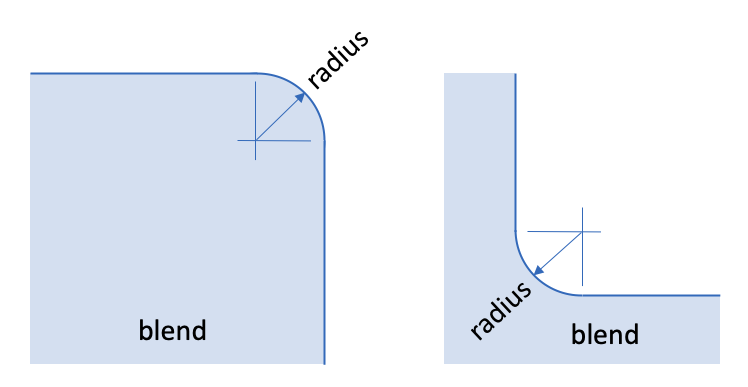

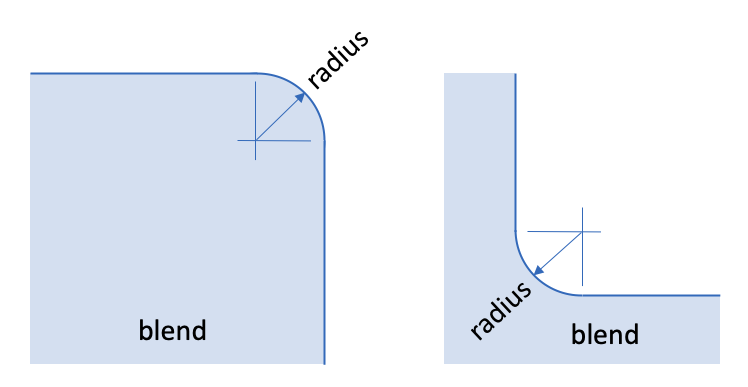

- Blend Chains - A blend surface serves as a smooth

transition between two neighboring surfaces, such as a fillet as shown

in Figure 8. Blends are identified as surfaces having a constant radius

along one of its parametric directions. Blends often occur as a chain

or connected set of surfaces and are displayed as a collection of

surfaces in the power tool that can be expanded and examined individually.

Enter a Blend Radius threshold value at the top of

Geometry power tools options panel to control the maximum radius of

curvature for surfaces returned from this test. The default value

for Blend Radius threshold is the current mesh_size.

Resulting blend surfaces are ordered based upon their minimum radius

of curvature. Blend chains can be candidates for the remove

surface blend_chain or split

surface commands.

Figure 9. Blend Examples

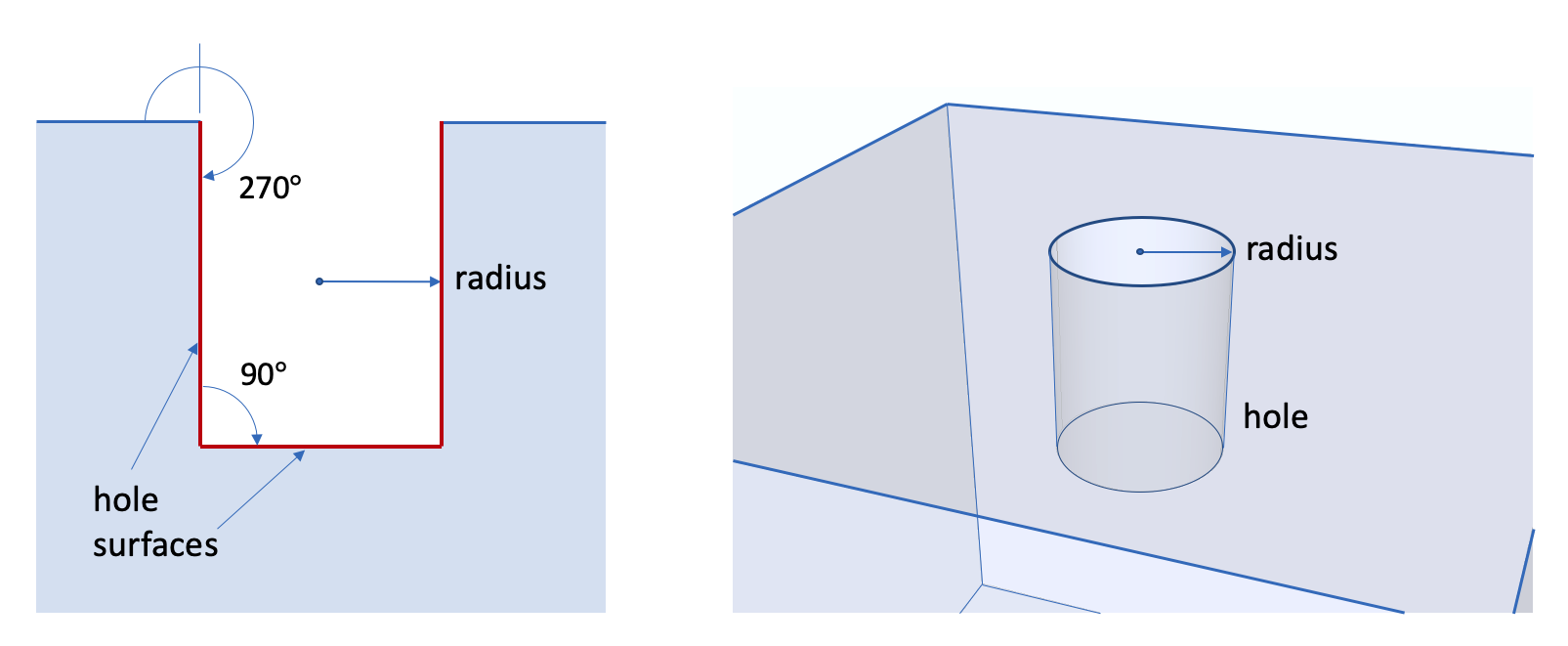

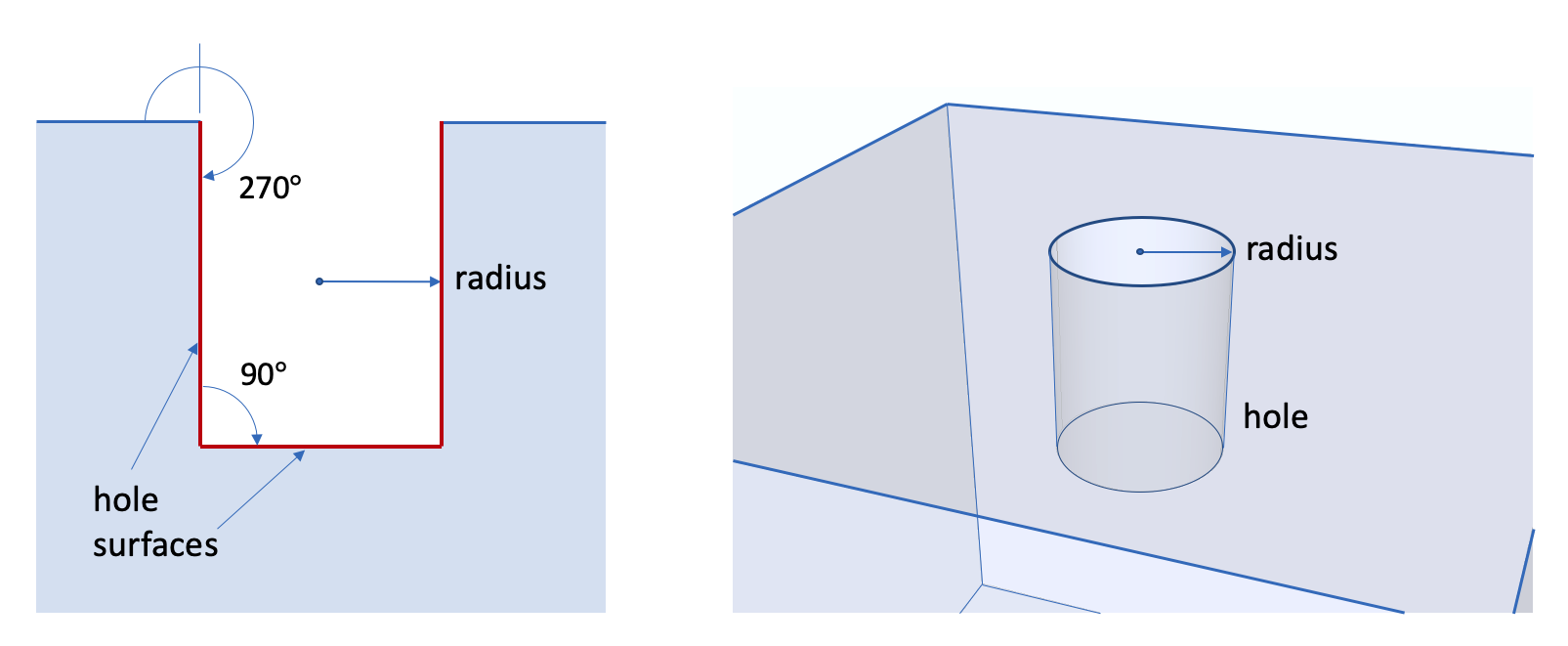

- Holes - Holes are a special category of Cavity

(see below). They are collections of surfaces that are bounded by

curves where the exterior angle is greater than 180 degrees and at

least one of the surfaces have a radius of curvature less than the

Hole Radius threshold. Figure 10 illustrates a hole

that is comprised of a cylindrical surface and a planar circular surface.

Resulting hole collections of surfaces are ordered based upon their

cylindrical radius. Holes can be candidates for the remove

surface cavity command.

Figure 10. Hole Example

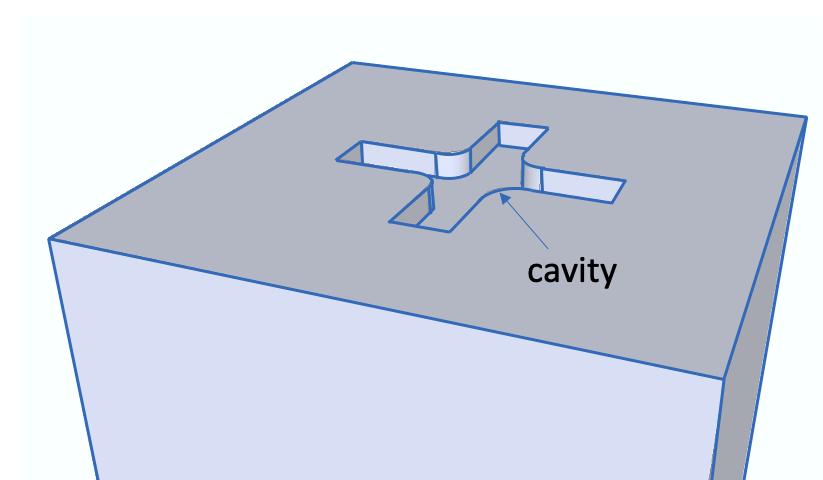

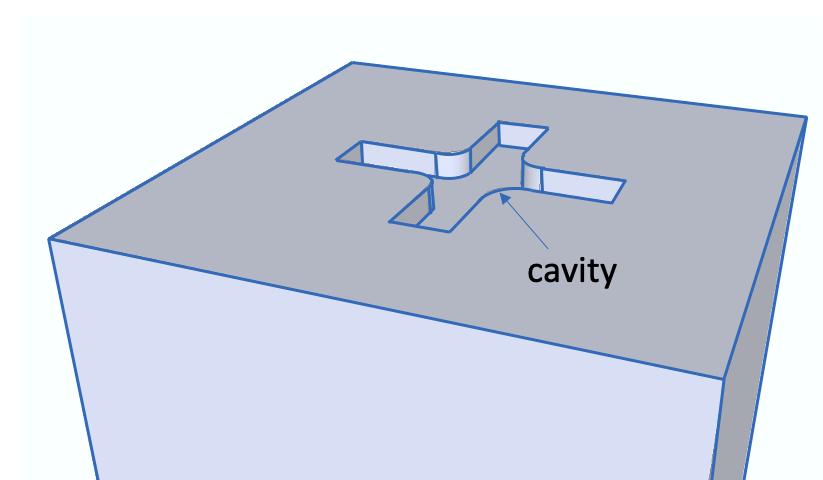

- Cavities - Small cavities in a volume may be candidates

for removal from the geometry. A cavity is defined as a collection

of surfaces bounded by curves with an external angle greater than

180 degrees. Enter the Cavity Area threshold value

at the top of the Geometry power tools Options panel. This value controls

the maximum total surface area for a cavity identified from this diagnostic

test. Since cavities may consist of many individual surfaces, the

resulting ordered list displayed in the power tool includes sub-lists

of surfaces that can be expanded and examined individually. Surfaces

contained with cavities or holes can be candidates for the remove

surface cavity command which will remove all surfaces

in the cavity sumiluatneously.

Figure 11. Cavity Example

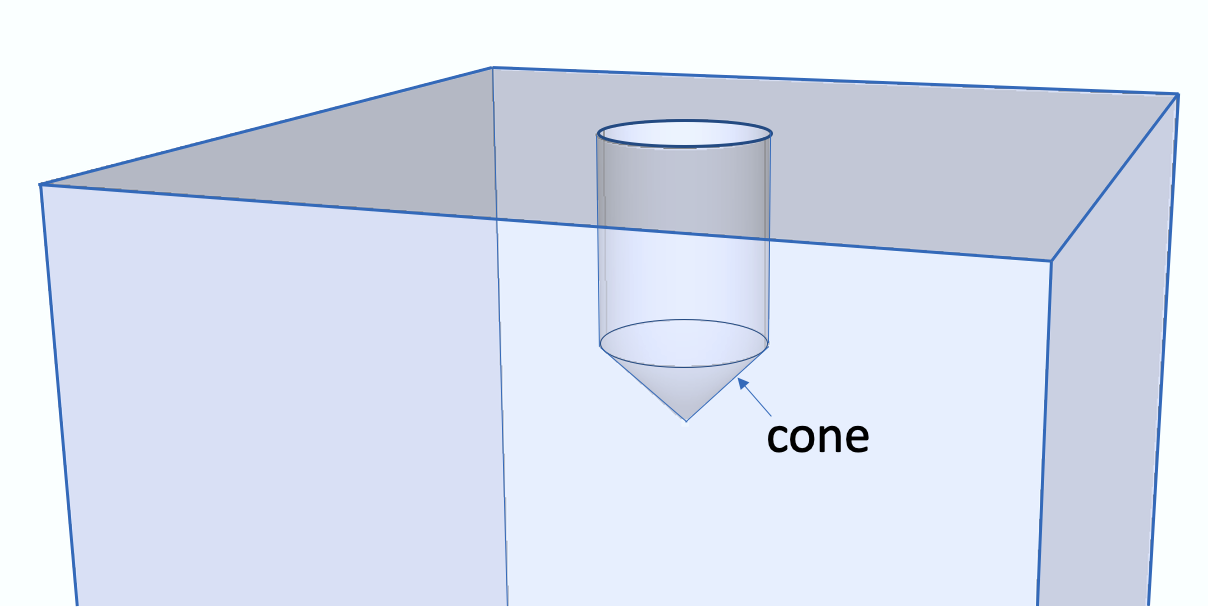

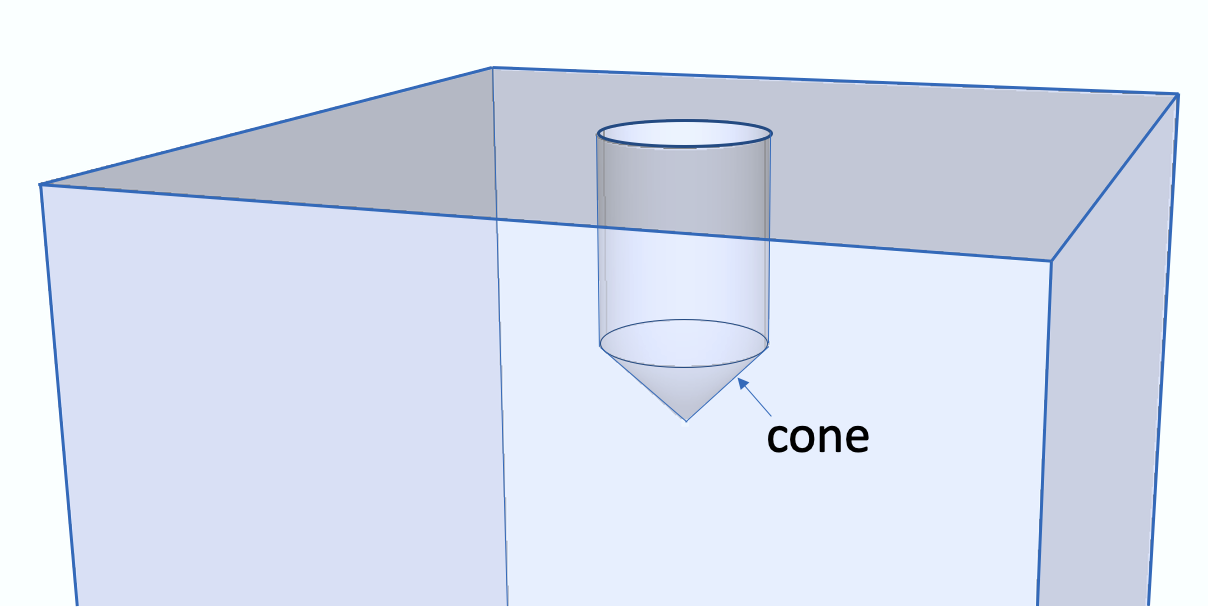

- Cone Surfaces - Cones are defined as any surface

comprising exactly two curves where one of the curves is of zero length.

Cone surfaces can often cause difficulty for surface meshing, and

should be removed when possible. Surfaces identified as cones are

ordered based on their surface area. Cone surfaces are good candidates

for the tweak

surface cone command.

Figure 12. Cone Example

- Bad Geometry Definition - Cubit uses third party

libraries, such as ACIS from Spatial, Inc. for much of its geometric

modeling capabilities. The bad geometry definition check calls internal

validation routines in these libraries, when available, to check for

errors in geometry definition. Entities indetified as "bad geometry"

are usually candidates for the heal

volume command. If the third party library does not provide

validation capabilities, this check will not return anything. Note:

ACIS is a trademark

of Spatial.

Check the interactions between multiple volumes. Here we check for overlaps,

gaps and misalignments between nearby volumes. It will also identify volumes

that are in contact as well as entities that are ready for merging.

For assemblies of volumes, it is important to identify if volumes will

be connected (imprinted and merged) are in contact, or separated by some

distance. The Assembly Checks provide diagnostics and

solutions to validate and resolve these interactions.

The Gaps, Overlaps and Misalignments

diagnostics normally identify undesirable conditions that must be resolved

prior to imprint

and merge.

Once resolved, the Volume Contacts and Mergable

Geometry can be used to validate connections before and after

imprinting and merging.

The Options panel also provides a way to estimate or manually set an

imprint tolerance. Entities closer than this tolerance will be considered

mergable when used with the tolerant

imprint command. When the Tolerant Imprint checkbox

is selected in the Options panel, the diagnostic tests that identify gaps,

overlaps and misalignments will also use the specified tolerance when

computing issues.

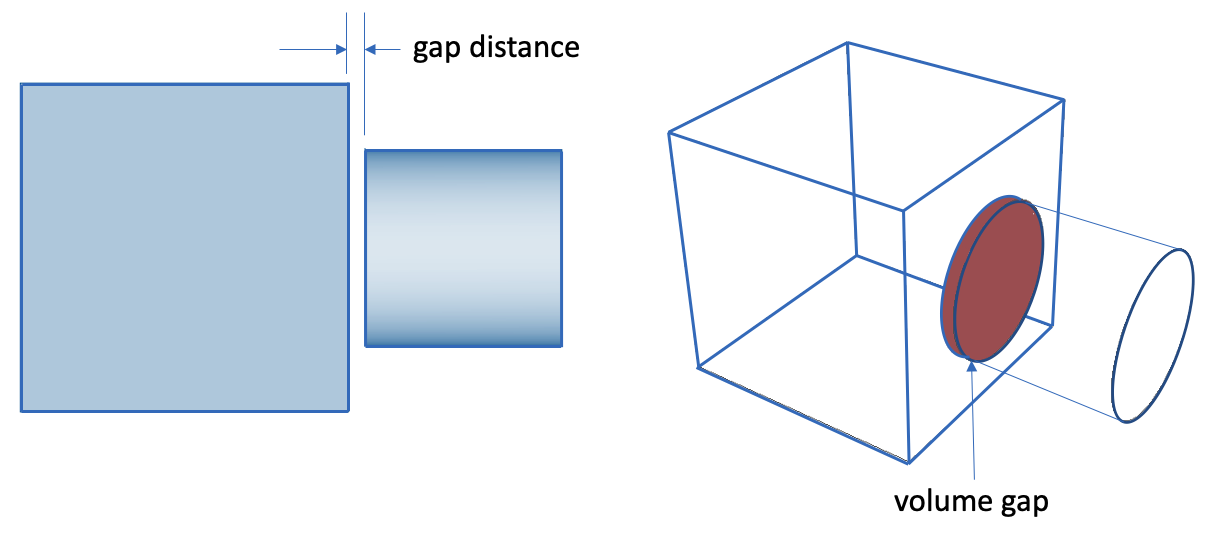

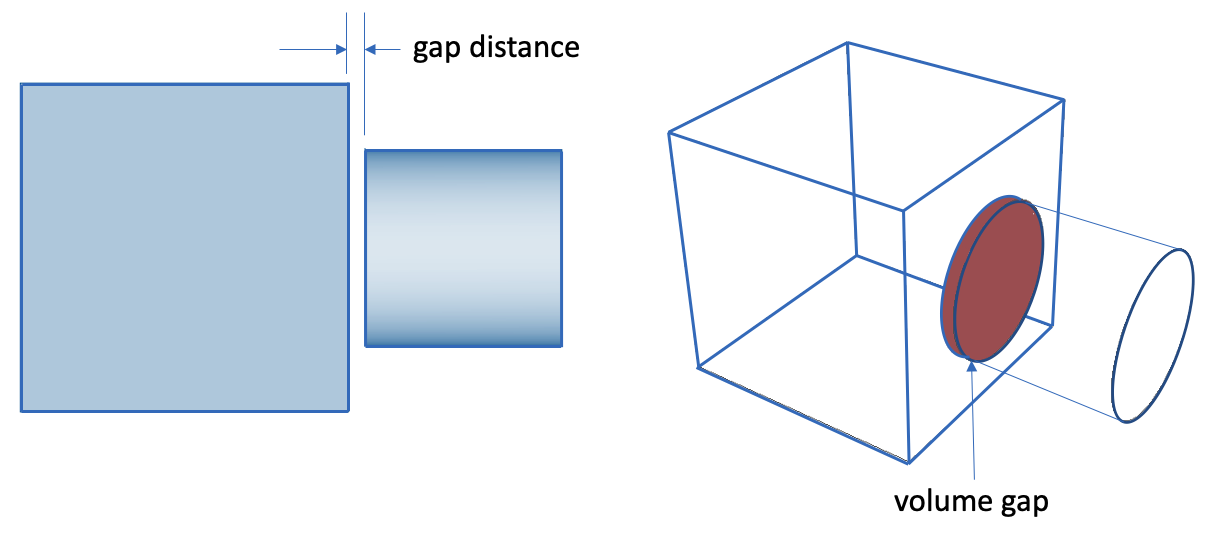

- Volume Gaps - Lists volume pairs that are separated

by a distance smaller than the Volume Gap tolerance

specified in the Options panel, but are not in contact or overlapping.

Gaps can result in parts that are not correctly merged and will not

share nodes between volumes when meshed. Expanding a volume pair in

the list will display individual surface pairs where gaps exist between

the volumes. Figure 13 illustrates a gap between two volumes. Gaps

can be visualized using the Draw Volume Gap context

menu, also shown in Figure 13, where the surfaces that are within

the gap tolerance are displayed in red. The tweak

surface replace command can sometimes be used to correct

overlaps.

Figure 13. Volume Gap

Example

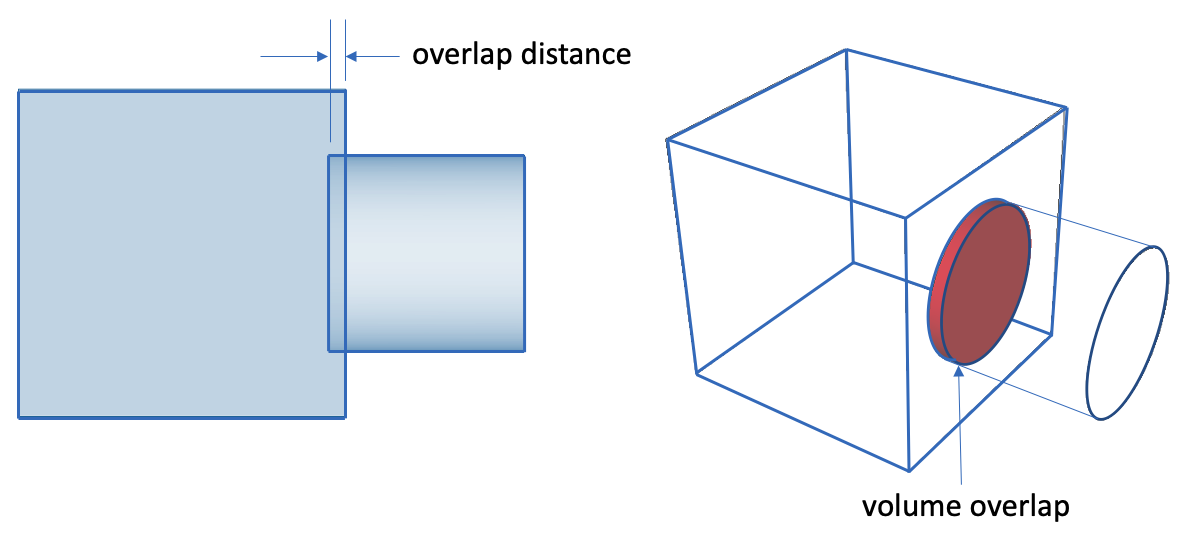

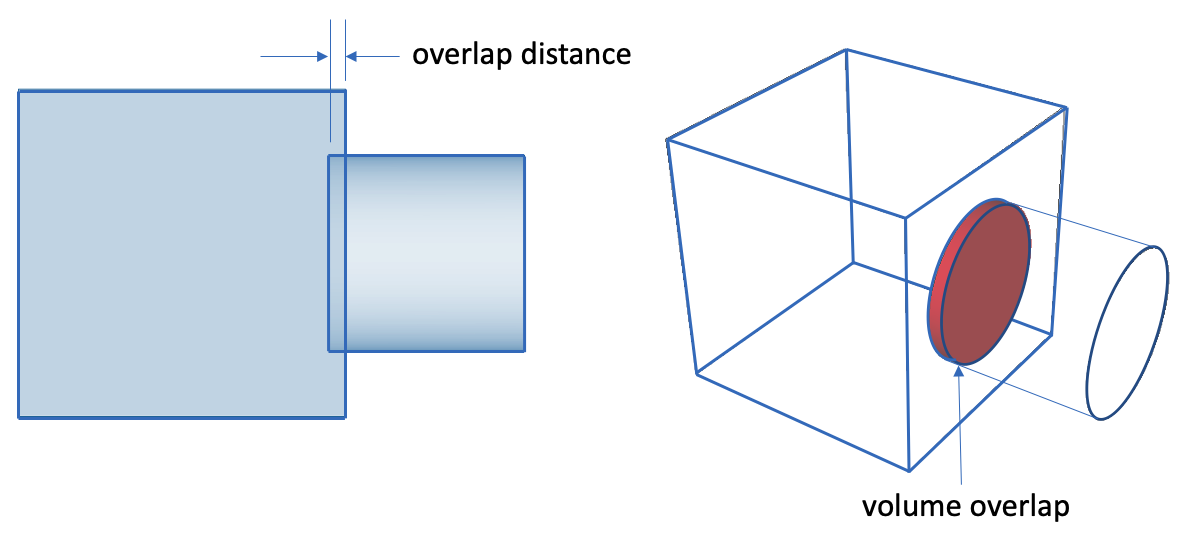

- Volume Overlaps - Lists volume pairs that are

overlapping. Figure 14. shows an example of a volume overlap. Overlapping

volumes can result in sliver surfaces and bad element quality if they

are not resolved prior to imprinting and merging. Overlaps can be

displayed with the context menu item, Draw Volume Overlap

which displays the overlap region in red. The remove

overlap command or tweak

surface replace commands can often be used to correct

overlaps.

Figure 14. Volume Overlap

Example

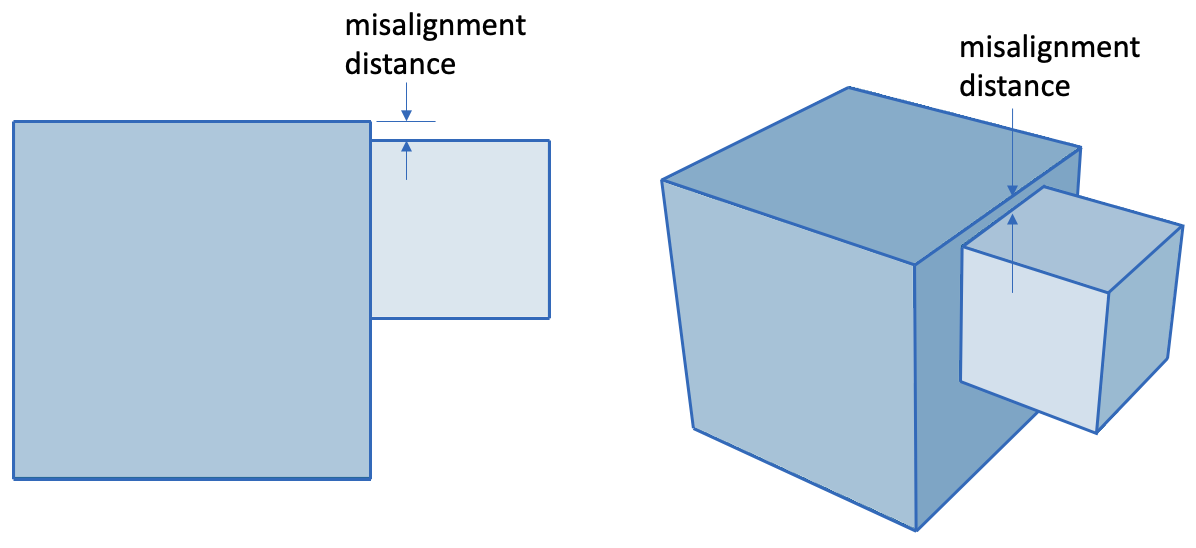

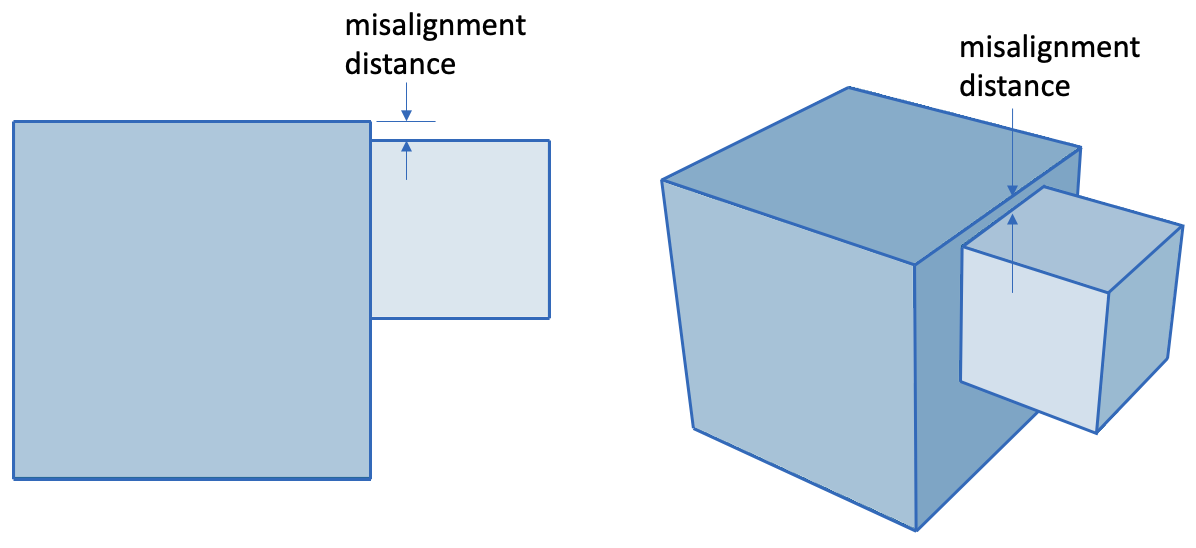

- Volume Misalignments - Misalignments are caused

when neighboring volumes touch without overlap, but a small distance

between neighboring vertices, curves or surfaces is identified. Figure

15 shows an example of a misalignment. Misalignments can result in

sliver surfaces and bad element quality if not resolved prior to imprinting

and merging. The Volume Misalignments diagnostic

test will list pairs of volumes that are misaligned. Expanding a volume

pair will reveal entity to entity misalignments that were detected

between the pair. Three categories of misalignments will be displayed,

namely: vertex-vertex, vertex-curve and vertex-surface ordered by

their misalignment distance. These indicate entity pairs that are

closer than the Volume Gap tolerance that is set

in the Options panel. The tweak

surface replace command can often be used to correct

misalignments.

Figure 15. Volume Misalignment

Example

- Volume Contacts - Volumes that have surfaces in

contact but not merged are displayed with this diagnostic test. This

provides a way to distinguish volumes that are merged from those that

are not and validate whether a contact state should exist between

neighboring volumes. This list will include volume pairs that are

touching including those that have been identified by the Volume

Misalignment diagnostic test. Expanding a volume pair will

reveal pairs of surfaces on different volumes that are in contact.

If the contact state is not correct, normally an imprint

and merge

operation should be performed

- Mergable Geometry - Pairs of entities on neighboring

volumes that are co-located are identified by this diagnostic test.

This is normally used to verify that the expected set of surfaces

are coincident prior to merging.

Mergeable geometry pairs of surfaces, curves and vertices are displayed

in this list. Lower order entities (ie. curves and vertices) will

not be displayed if its parent geometry (ie. surface) is identified

as mergeable. In most cases, lower order entities identified by this

diagnostic indicate the existence of overlaps or misalignments and

should be resolved before imprint and merging. Note that the default

merge tolerance of 1e-6 is used to determine if entities are mergeable

unless the Tolerant Imprint checkbox is selected

in the Options panel and a user defined tolerance is set.

Geometry Repair Tools

The geometry repair tool buttons appear at the bottom of the Geometry Power

Tool. Selecting one of these buttons will bring up the relevant command

panel. Tools included in this panel have proven useful for geometry repair

and defeaturing.

Split Surface

Button

Split Surface

Button

The split

surface tool is used to split a surface into two surfaces. This is

useful for blend surfaces, for example, where splitting a surface may

facilitate sweeping. To select a surface for splitting, click on the surface

in the tree view. To select multiple surfaces in the window, hold the

CTRL key* while selecting surfaces (surfaces must be attached to each

other). Then press the split surface button to bring up the Control Panel

window with the ids of selected surfaces in the text input window. The

split surface menu is located on the Control Panel under Geometry-Surface-Modify.

You must press the Apply button for the command to be executed. You can

also bring up the Split Surface menu by selecting surfaces in the tree

view and selecting Split from the right click menu.

*Note: For Mac computers,

use the command key (or apple key) to select multiple entities

Heal Button

Heal Button

The healing

function in Cubit is used to improve ACIS geometry that has been corrupted

during file import due to differences in tolerances, or inherent limitations

in the parent system. These errors may include: geometric errors in entities,

gaps between entities, and the absence of connectivity information (topology).

To heal a volume, select the volume in the geometry repair tree view.

Then press the heal button. You may also press the heal button without

a geometry selected in the window, and enter it later. The Control Panel

window will come up under the Geometry-Volume-Modify option with the selected

volume id highlighted. If no entity is selected, or if another entity

type is selected, the input window will be blank. You can also open the

healing control panel by selecting Heal from the right

click menu in the geometry power tools window.

Tweak Button

Tweak Button

The tweak

command is used to eliminate gaps between entities or simplify geometry.

The tweaking commands modify geometry by offsetting, replacing, or removing

surfaces, and extending attached surfaces to fill in the gaps. Tweaking

can be applied to surfaces, and it can be applied to curves with a valence

no more than 2 at each vertex. It can also be applied to some vertices.

To tweak a surface, select the surface in the tree view. The Geometry-Surface-Modify

control panel will appear with the selected surface id in the input window.

Tweaking is available for curves.

Tweaking a curve creates a blended or chamfered edge between two orthogonal

surfaces. The curve option is located on the Geometry-Curve-Modify panel

under the Blend/Chamfer pull-down option.

Tweaking is also available for some vertices.

Tweaking a vertex creates a chamfered or filleted corner between three

orthogonal surfaces. The vertex option is located on the Geometry-Vertex-Modify

panel under the Tweak pull-down menu.

Note: Only curves with valence 2

or less at each vertex are candidates for tweaking. Any other curve will

cause the Geometry-Surface-Modify menu to appear.

Merge Button

Merge Button

The merge

command is used to merge coincident surfaces, curves, and vertices into

a single entity to ensure that mesh topology is identical at intersections.

Unlike other buttons on the geometry repair panel, the merge button acts

as an "Apply" button itself. All geometry that is listed under

"mergeable entities" will be merged.

Remove Button

Remove Button

The remove

button is used to simplify geometry by removing unnecessary features.

To use the remove feature, click on the surface(s) in the Tree View. Right

click and select the Remove Option, or click the Remove icon on the toolbar.

The Control Geometry-Surface-Modify control panel will appear, with the

surface ids in the input window. The Remove control panel can also be

accessed from the right-click menu in the Geometry Power Tools window.

Select options and press apply.

Regularize Entity

Button

Regularize Entity

Button

The regularize

button is used to remove unnecessary topology. Regularizing an entity

will essentially undo an imprint command.

Remove Slivers

Remove Slivers

The remove

slivers button is used to remove surfaces with less than a specified

surface area. When ACIS removes a surface it extends the adjoining surfaces

to fill the gap. If it is not possible to extend the surfaces or if the

geometry is bad the command will fail.

Auto Clean Geometry

Auto Clean Geometry

The auto

clean button is used to perform automatic cleanup operations on selected

geometry. These automatic cleanup operations include forcing sweepable

configurations, automatically removing small curves, automatically removing

small surfaces, and automatically splitting surfaces.

Composite Button

Composite Button

The composite

button is used to combine adjacent surfaces or curves together using virtual

geometry . Virtual geometry is a geometry module built on top of the

ACIS representation. Surfaces may be composited to simplify geometry in

order to facilitate sweeping and mapping algorithms by removing constraints

on node placement. It is important to note that solid model operations

such as webcut, imprint, or booleans, cannot be applied to models that

have virtual geometry. Both curves

and surfaces

may be composited.

Collapse Angle

Button

Collapse Angle

Button

The collapse

angle button uses virtual

geometry to collapse small angles. This is accomplished by partitioning

and compositing surfaces in a way so that the small angle gets merged

into a larger angle. Pressing the collapse button on the geometry power

tools will open the collapse menu under Geometry-Vertex-Modify control

panel. This panel can also be opened by selecting Collapse

from the right click menu in the Geometry Tools window.

Collapse Surface Button

Collapse Surface Button

Pressing this button will open the collapse surface panel on the main

control panel. The collapse

surface function uses virtual geometry to eliminate small surfaces

on the model to improve mesh quality. It is most useful for blend surfaces.

Collapse Curve Button

Collapse Curve Button

Pressing this button will open the collapse curve panel on the main

control panel. The collapse

curve command is used to eliminate small curves using virtual geometry.

Reset Graphics

Button

Reset Graphics

Button

The reset graphics button will refresh

the graphics window display.

Note: Pressing most of the geometry

tool buttons on the panel will only bring up applicable command panels

on the Control Panel. You must press the Apply button on the Control Panel

to execute the command.

Context (Right Click) Menu

The following right click menu options are available from the geometry

power tool's main window when a geometry entity or category is selected.

Figure 3. shows an example of a context menu. Specific options depend

on the type of entity or category.

Test Categories

- Select All - Selects

all entities in the category

- Draw All - Draw

all entities in the category

- Draw All Add - Draw

all entities in the category without first clearing the display

- Locate All - Labels

all entities in the category in the graphics window. Refresh screen

to hide.

- Expand All - Expand

all categories to show sub-lists of entities

- Collapse All - Collapse

all categories to hide sub-lists of entities

Entity Visualization Options

- Zoom To- Zoom

to selected entity in the graphics window

- Reset Zoom - Reset

graphics window zoom

- Fly-in - Animated zoom

- Locate - Labels the

selected entities in the graphics window. Refresh screen to hide.

- Draw - Displays

only selected entities by themselves.

- Draw Add - Adds the

selected entity to the display without clearing.

- Draw with Neighbors

- Displays

only selected entities with all attached neighbors

- Select Similar ...

- Selects other entities in the same category that have the same geometry

characteristic. For example, area, loop thickness, blend radius, angle

at vertex, etc.

- Clear Blend Chain -

Available in Blend category. Selects surfaces in the same blend chain

as the selected surface.

- Clear Cavity/Hole -

Available in Cavity/Hole category. Selects surfaces in the same cavity

or hole collection as the selected surface.

- Clear Selections -

Clears all highlighted entities and reset graphics

Cubit Solution Options

Each of the following menu options are available based on the category

and entity type selected. In each case they will open the relevant command

panel pre-populated with the entity selected. Select multiple entities

prior to selecting the context menu item below to execute the command

on multiple entities simulaneously.

![]() Split Surface

Button

Split Surface

Button![]() Heal Button

Heal Button![]() Tweak Button

Tweak Button![]() Merge Button

Merge Button![]() Remove Button

Remove Button![]() Regularize Entity

Button

Regularize Entity

Button![]() Remove Slivers

Remove Slivers![]() Auto Clean Geometry

Auto Clean Geometry![]() Composite Button

Composite Button![]() Collapse Angle

Button

Collapse Angle

Button![]() Collapse Surface Button

Collapse Surface Button![]() Collapse Curve Button

Collapse Curve Button![]() Reset Graphics

Button

Reset Graphics

Button