Sandia is moving into the demonstration phase of a novel gas turbine system for power generation, with the promise that thermal-to-electric conversion efficiency will be increased to as much as 50 percent — an improvement of 50 percent for nuclear power stations currently equipped with steam turbines, or a 40 percent improvement for simple gas turbines. It is also very compact, meaning that capital costs would be relatively low.

Research focuses on supercritical carbon dioxide (S-CO2) Brayton cycle turbines, which typically would be used for bulk thermal and nuclear generation of electricity, including next-generation power reactors (see Sandia Lab News, Dec. 5, 2008). The goal is eventually to replace steam-driven Rankine cycle turbines, which have lower efficiency, are corrosive at high temperature, and occupy 30 times as much space because of the need for very large turbines and condensers to dispose of excess steam. The Brayton cycle could yield 20 megawatts electrical (MWe) from a package with a volume as small as four cubic meters.

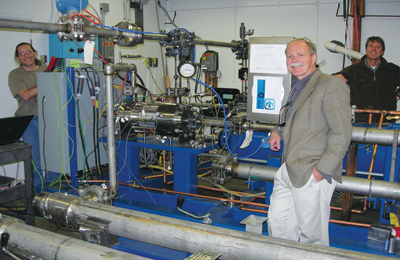

“This machine is basically a jet engine running on a hot liquid,” says principal investigator Steve Wright of Advanced Nuclear Concepts Dept. 6221. “There is a tremendous amount of industrial and scientific interest in supercritical CO2 systems for power generation using all potential heat sources including solar, geothermal, fossil fuel, biofuel, and nuclear.”

Sandia currently has two supercritical CO2 test loops (the term loop derives from the shape taken by the working fluid as it completes each circuit). A power production loop is located at the Arvada, Colo., site of contractor Barber Nichols Inc., where it has been running and producing approximately 240 kilowatts (electrical) during the developmental phase that began in March 2010. It is now being upgraded and is expected to be shipped to Sandia this summer. A second loop, located in Sandia’s Tech Area 5, is a research device to understand the unusual issues of compression, bearings, seals, and friction that exist near the critical point, where the carbon dioxide has the density of liquid but otherwise has many of the properties of a gas.

Immediate plans call for Sandia to continue to develop and operate the small test loops to identify key features and technologies. Test results will illustrate the capability of the concept, particularly its compactness, efficiency, and scalability to larger systems. Future plans call for commercialization of the technology and development of an industrial demonstration plant at 10 MWe.

A competing system, using Brayton cycles with helium as the working fluid, is designed to operate at about 925 Celsius and is expected to produce electrical power at 43 percent to 46 percent efficiency. By contrast, the supercritical CO2 Brayton cycle provides the same efficiency as helium Brayton systems but at a considerably lower temperature (250-300 Celsius). The S-CO2 equipment is also more compact than that of the helium cycle, which in turn is more compact than the conventional steam cycle.

Under normal conditions materials behave in a predictable, classical, “ideal” way as conditions cause them to change phase, as when water turns to steam. But this model tends not to work at lower temperatures or higher pressures than those that exist at these critical points. In the case of carbon dioxide, it becomes an unusually dense “supercritical” liquid at the point where it is held between the gas phase and liquid phase. The supercritical properties of carbon dioxide at temperatures above 500 Celsius and pressures above 7.6 megapascals enable the system to operate with very high thermal efficiency, exceeding even those of a large coal-fired power plant and nearly twice as efficient as that of a gasoline engine (about 25 percent).

In other words, as compared with other gas turbines the S-CO2 Brayton system could increase the electrical power produced per unit of fuel by 40 percent or more. The combination of low temperatures, high efficiency, and high power density allows for the development of very compact, transportable systems that are more affordable because only standard engineering materials (stainless steel) are required, less material is needed, and the small size allows for advanced-modular manufacturing processes.

“Sandia is not alone in this field, but we are in the lead,” Steve says. “We’re past the point of wondering if these power systems are going to be developed; the question remains of who will be first to market. Sandia and DOE have a wonderful opportunity in the commercialization effort.”

Other individuals who contributed substantially to this project are Robert Fuller (Barber Nichols Inc.), Paul Pickard (Sandia retired), Milton Vernon (6221), Keith Barrett (PrimeCore Inc.), Ross Radel (former Sandian), Thomas Conboy (6221), and Gary Rochau, (manager 6621).

Sandia’s S-CO2 Brayton cycle program is supported by DOE with funding from the Labs’ Laboratory Directed Research & Development (LDRD) program.