Sandia and a team of government and university labs are building a prototype mortar launcher that could alter the way armies have launched projectiles at their enemies for a thousand years.

As part of a two-year electromagnetic mortar project for the Defense Advanced Research Projects Agency (DARPA), the research team is building a prototype electromagnetic (EM) gun and demonstrating electromagnetic launch of mortar-class munitions. Full-scale field testing is scheduled for this fall at Sandia.

Partners in the project include the Institute of Advanced Technology at the University of Texas; the Munitions Development Division of the US Army Armaments Research, Development, and Engineering Center; and capacitor film manufacturing company TPL, Inc.

The DARPA-funded project focuses on low-cost, high-fire-rate munitions. A complementary joint Sandia project with Lockheed Martin is demonstrating EM-launched missile systems (Lab News, Jan. 21, 2005).

In conventional mortar-firing operations, crews determine mortar range by the amount of propellant (the number of individually packaged propellant charges behind the round), barrel attitude, and external factors such as terrain features and wind direction.

The science is essentially unchanged since 11th-century Chinese combatants used the first crude gunpowder-propelled projectiles to decimate enemy lines. Later in Europe, 15th-century armies perfected the use of cannonballs to pulverize castle walls.

“Although today’s mortar crews become very good over time, launching mortars is by today’s standards an inexact science, and it is constrained by the incremental degree of control offered by propellant rings,” says Bob Turman, Senior Manager for Directed Energy Systems Org. 5440.

In an electromagnetic launcher, coils stacked along the gun’s barrel are subjected to precisely timed current pulses, one after the other, creating a magnetic wave that moves quickly up the barrel and pushes the mortar and armature along with it.

No propellant is necessary, eliminating not only a safety hazard for soldiers and a logistics headache for the military, but also a major source of imprecision in conventional mortar guns. A very slight variation in propellant quality, temperature, or quantity can result in a mortar missing its target.

“There is only so much fidelity you can get with propellant rings,” says project manager Ron Kaye (5445).

The barrel-end velocity of an EM-launched projectile, on the other hand, when timed by computer, can be very precisely controlled, he says. The intensity with which individual coils are fired in succession can also be adjusted on the fly to make slight adjustments, literally while the mortar is traversing the barrel.

“This will allow the warfighter to essentially dial a range,” says Ron. “It will allow for a new degree of control.”

Because no propellant loading is necessary, launch cycle times can be reduced from the 10 rounds-per-minute maximum of a skilled mortar crew to, Bob estimates, 16 to 24 rounds per minute —determined by the time required to reload the mortar and recharge the energy-storage capacitors. Eliminating the propellant also opens the door to fully automated, robotically reloaded EM mortar guns that might achieve even faster fire rates.

EM guns produce almost no muzzle flash and a fraction of the muzzle report associated with traditional artillery. In essence, the mortar departs the barrel with a swoosh rather than a bang. In today’s world of space- and aircraft-based reconnaissance sensing, reducing the optical and acoustic signal will make it more difficult for the enemy to pinpoint the source of artillery fire, says Ron.

Sandia’s DARPA project focuses on land-based army munitions, and the Sandia team has built a nonfunctional replica of a turret containing an EM gun that could sit atop a Future Combat System vehicle or Bradley fighting vehicle.

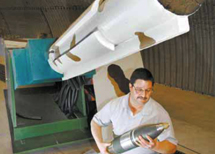

A full-scale, 50-coil EM gun prototype has been designed and is being built in Area 4.

Projectile interaction with the EM gun barrel components have been modeled on Sandia computers and validated using data from a four-coil mock-up gun. Laboratory tests on the full-scale prototype are scheduled for this fall.

For vehicle applications, a portable electrical power generation and capacitance-based storage system would be necessary, which Bob believes need be only as large and weighty as the turrets on current military platforms.

DARPA is considering EM mortar launchers as a potential component of the US military’s Future Combat System. If hybrid electric vehicles are adopted, the EM launcher could, essentially, share an on-board power plant with its host vehicle, says Ron.

The Sandia-led project falls in the category of applied development and goes well beyond the research projects conducted at Sandia in the early ‘90s that resulted in demonstration of an EM-launched projectile across Coyote Canyon, says Bob.

“DARPA has provided the specifications and the parameters and asked us to build them a mortar demonstration using existing 120 mm mortar ammunition,” he says. “We’re getting close to a working, full-scale gun.”