13.2. B. Implicit Quasistatic Example Problem

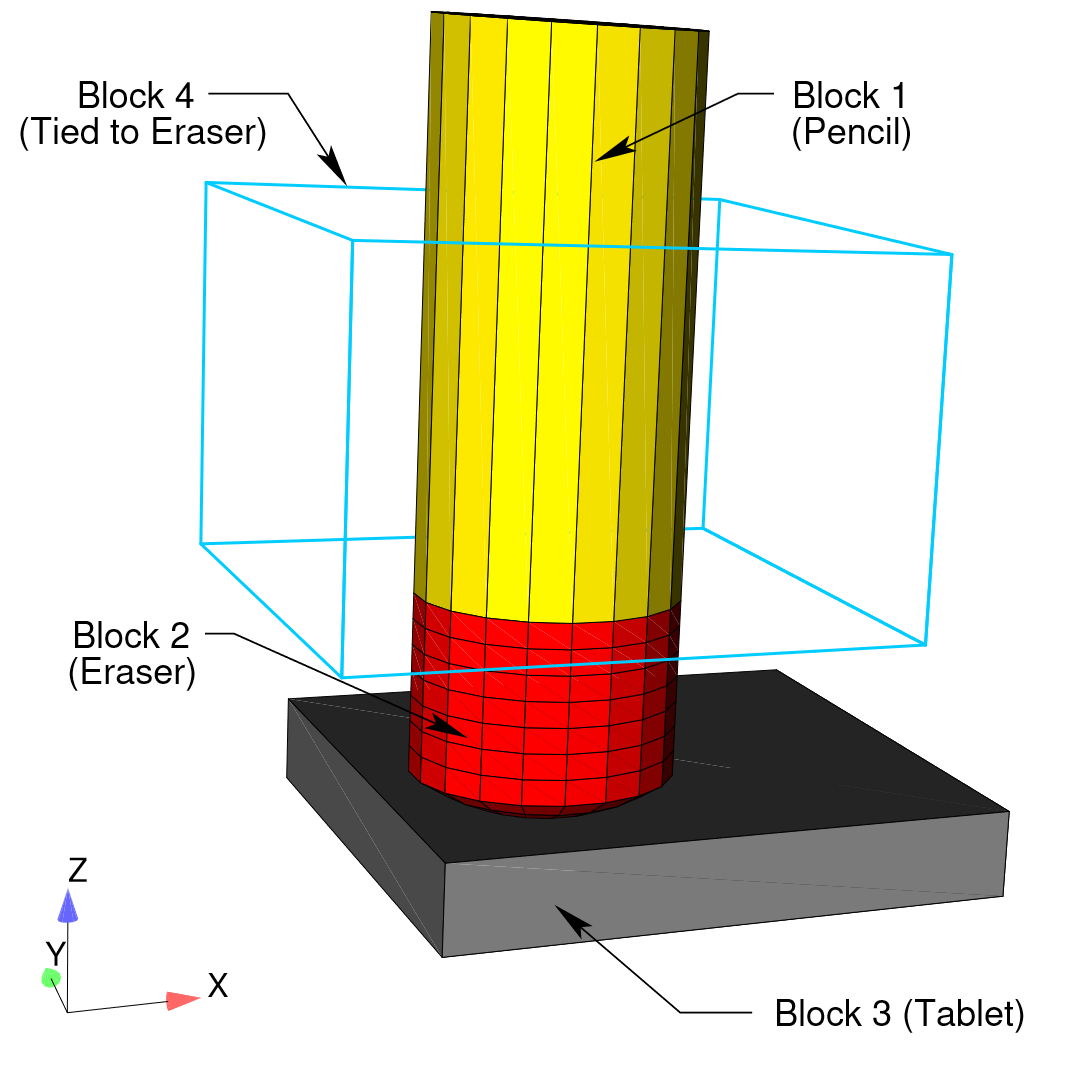

This appendix provides an example problem to illustrate the construction of an input file for an analysis. The problem is modeled after a pencil/eraser that is pressed against and rubbed across a tablet. The pencil, eraser and tablet are represented by blocks 1, 2 and 3 respectively. Block 4 is used to apply kinematics directly to the eraser via tied contact between block 4 and block 2. Block 1 is superfluous except when viewed together with blocks 1, 2 and 3. Then they closely resemble a pencil with an eraser on a tablet. The problem demonstrates the overall structure of an input file and includes the use of both tied and frictional contact simultaneously, the multilevel solver, and a linear solver for preconditioning. A schematic of the problem is shown in Fig. 13.3 and the mesh is shown in Fig. 13.4.

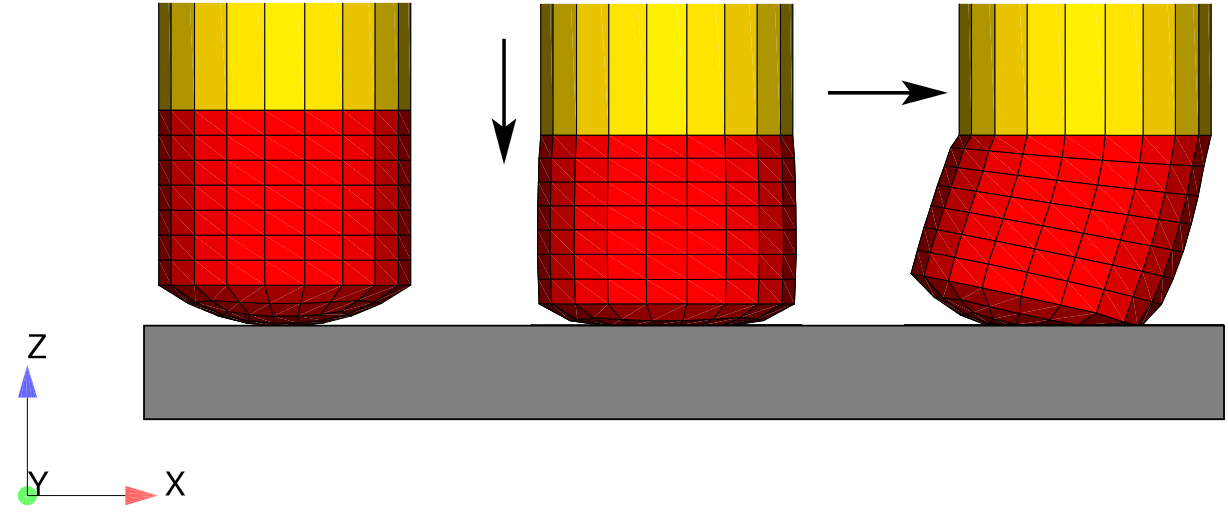

Fig. 13.3 Eraser schematic; Block 1 (yellow) is pencil, block 2 (red) is eraser, block 3 (gray) is tablet, block 4 (not shown) is tied to eraser and has the kinematics applied to it.

Fig. 13.4 Complete eraser mesh.

The problem kinematics and loading are described briefly here. The loading has two phases: preload and sliding. In the preload phase, the tablet (block 3) is kinematically fixed in the \(x\)-\(y\) plane and a vertical load (in the \(z\)-direction) is applied to the tablet which presses the tablet against the eraser (block 2). The eraser is kinematically fixed to block 4 via tied contact (see Fig. 13.4). Block 4 is held fixed in all three coordinate directions for the compression phase. The initial configuration and deformations of the preload phase are shown in the first two snapshots on the left in Fig. 13.3. In the sliding phase, block 4 is kinematically prescribed to move along the \(x\)-direction, thus sliding or dragging the eraser along the tablet (see Fig. 13.3) while the tablet force is held constant.

The input file is described below, with comments to explain every few lines. Following the description, the full input file is listed again. All character strings in the input file are presented in lowercase, which is an acceptable format in Adagio.

The input file starts with a begin sierra statement, as is required for all input files:

begin sierra eraser

We begin by defining vectors corresponding to the coordinate axes. These vectors/directions will be used to define the input for boundary condition blocks that come later.

define direction X with vector 1.0 0.0 0.0

define direction Y with vector 0.0 1.0 0.0

define direction Z with vector 0.0 0.0 1.0

We now need to define the functions used for this problem. The boundary conditions require a function for the tablet force and the sliding motion. Both the tablet force and sliding motion are prescribed as functions of time.

begin function slide

type is piecewise linear

begin values

0.0 0.0

1.0 0.0

2.0 1.0

3.0 1.0

end values

end function slide

begin function tablet_force

type is piecewise linear

begin values

0.0 0.0

1.0 1.0

3.0 1.0

end values

end function tablet_force

begin function zero

type is constant

begin values

0.0

end values

end function zero

The tablet force ramps up over the time interval (0.0, 1.0) and then is held constant over the interval (1.0, 3.0). The sliding function is zero over the time interval (0.0, 1.0) and then it linearly increases over the interval (1.0, 2.0). Next, we define the material properties and models that are used in this problem. In this example, we define two sets of material properties: one is called stiff (pencil, tablet, and block 4), and the second is called soft (eraser). We use a linear elastic constitutive model for both cases.

begin material stiff

density = 1.0

begin parameters for model elastic

youngs modulus = 1.e5

poissons ratio = 0.3

end parameters for model elastic

end material stiff

begin material soft

density = 1.0

begin parameters for model elastic

youngs modulus = 1000.

poissons ratio = 0.3

end parameters for model elastic

end material soft

Now, we define the finite element mesh. This includes specification of the file that contains the mesh, a list of all the element blocks we will use from the mesh and the material associated with each block. The name of the file is eraser.g. The specification of the database type is optional-ExodusII is the default. Currently, each element block must be defined individually. The tablet, pencil and block 4 all reference the same material description (stiff). The material description is not repeated three times. The material description for stiff appears once and is then referenced three times.

begin finite element model mesh1

database name = eraser.g

database type = exodusII

begin parameters for block block_1 #Pencil

material = stiff

model = elastic

end

begin parameters for block block_2 #Eraser

material = soft

model = elastic

end

begin parameters for block block_3 #Tablet

material = stiff

model = elastic

end

begin parameters for block block_4 #dummy block

material = stiff

model = elastic

end

end finite element model mesh1

At this point we have finished specifying physics-independent quantities. We now want to set up the Adagio procedure and region, along with the time control command block. We start by defining the beginning of the procedure scope, the time control command block, and the beginning of the region scope. Three time stepping command blocks are used in this analysis. The termination time is set to 1.8. Having multiple time blocks is useful because we can make some solver options a function of the time block.

begin adagio procedure agio_procedure

begin time control

begin time stepping block preload

start time = 0.0

begin parameters for adagio region adagio

number of time steps = 5

end parameters for adagio region adagio

end time stepping block preload

begin time stepping block slide_1

start time = 1.0

begin parameters for adagio region adagio

number of time steps = 1

end parameters for adagio region adagio

end time stepping block slide_1

begin time stepping block slide_2

start time = 1.1

begin parameters for adagio region adagio

number of time steps = 10

end parameters for adagio region adagio

end time stepping block slide_2

termination time = 1.8

end time control

begin adagio region adagio

Next we associate the finite element model we defined above (mesh1) with this Adagio region.

use finite element model mesh1

Now we define the kinematic boundary conditions. First, we prescribe the displacement of surface_200 which is part of block 4. We fix this surface in both the \(x\) and \(z\) directions and prescribe the horizontal displacement along the X-direction using the previously defined functions zero and slide.

### movement of pencil prescribed by block 4

begin prescribed displacement

surface = surface_200

direction = X

function = slide

scale factor = 3.0

end prescribed displacement

begin fixed displacement

surface = surface_200

components = Y Z

end fixed displacement

Next, we fix the tablet and prevent it from moving in the X-Y plane. We do this on all tablet nodes (nodelist_111 and nodelist_112).

### Constraints on tablet

begin fixed displacement

node set = nodelist_111

components = X Y

end fixed displacement

begin fixed displacement

node set = nodelist_112

components = X Y

end fixed displacement

Finally, we prescribe preload force on the tablet which compresses the tablet against the eraser.

### Tablet force

begin prescribed force

node set = nodelist_111

direction = Z

function = tablet_force

scale factor = 100.0

end prescribed force

We now define the contact for this problem. Here we need to define tied contact between block 4 and the eraser. In addition, we have frictional sliding contact between the tablet and the eraser.

### block 4 tied to eraser ###

begin contact definition

#

# define contact surfaces.

contact surface surf_200 contains surface_200

contact surface surf_110 contains surface_110

contact surface surf_11 contains surface_11 # Tablet

contact surface surf_10 contains surface_10 # Eraser

#

begin interaction

surfaces = surf_200 surf_110

friction model = tied

end interaction

begin interaction

surfaces = surf_11 surf_10

friction model = fric

end interaction

begin constant friction model fric

friction coefficient = 0.8

end

end contact definition

Now we define what variables we want in the output file and how often we want the output file to be written. The output file will be called eraser.e, and it will be an ExodusII file (the database type command is optional; it defaults to ExodusII). The variables we are requesting are the displacements, velocities, and contact diagnostics at the nodes, and stresses and strains at the elements.

begin results output output_adagio

database name = eraser.e

database type = exodusII

at step 0, increment = 1

nodal displacement as displ

nodal velocity as vel

nodal contact_tangential_direction as cont_tan

nodal contact_normal_direction as cont_norm

nodal contact_accumulated_slip_vector as cont_slip_vec

nodal contact_status as cont_stat

nodal contact_normal_traction_magnitude as norm_trac_mag

nodal contact_tangential_traction_magnitude as tan_trac_mag

nodal contact_incremental_slip_magnitude as cont_Islip_mag

nodal contact_accumulated_slip as cont_Aslip

nodal contact_frictional_energy_density as cont_fric_E

nodal contact_area

element stress as stress

element log_strain as strain

end results output output_adagio

The final part of the input deck is the Adagio solver commands. Because we are solving an implicit problem, we must use the solver command block. Nested inside the solver block, we define the control contact block as well as the nonlinear conjugate gradient (CG) solver block.

begin solver

begin control contact name

target relative residual = 1e-3

Maximum Iterations = 200

end control contact name

begin cg

target relative residual = 1.e-4

begin full tangent preconditioner

linear solver = feti

end full tangent preconditioner

end cg

end solver

After defining the Adagio region and procedure blocks, we close them using the lines:

end adagio region adagio

end adagio procedure agio_procedure

The final detail that we need to define for this file is the linear solver. In the above solver command block, we included the full tangent preconditioner block, which has a nested command line linear solver = feti. This command line refers to a linear solver called feti that must be defined outside the “Procedure” scope but within the “Sierra” scope and can come at the top of the file before the “Procedure” definition or after it as is the case here. The input feti on this line command is a user defined string that can have any useful label. The following command block defines the linear solver labeled feti. Note that the command block has the label feti at the end of the Begin line and that this label is referred to from within the above full tangent preconditioner command block. The FETI parameters are all set to reasonable values for most problems, so there is no need to set any of them, but if it were necessary to set any of them to non-default values, that would be done within the feti equation solver block.

begin feti equation solver feti

# use default settings

end feti equation solver feti

Finally, we finish the input file and close the sierra command block:

end sierra eraser