13.1. A. Explicit Dynamics Example Problem

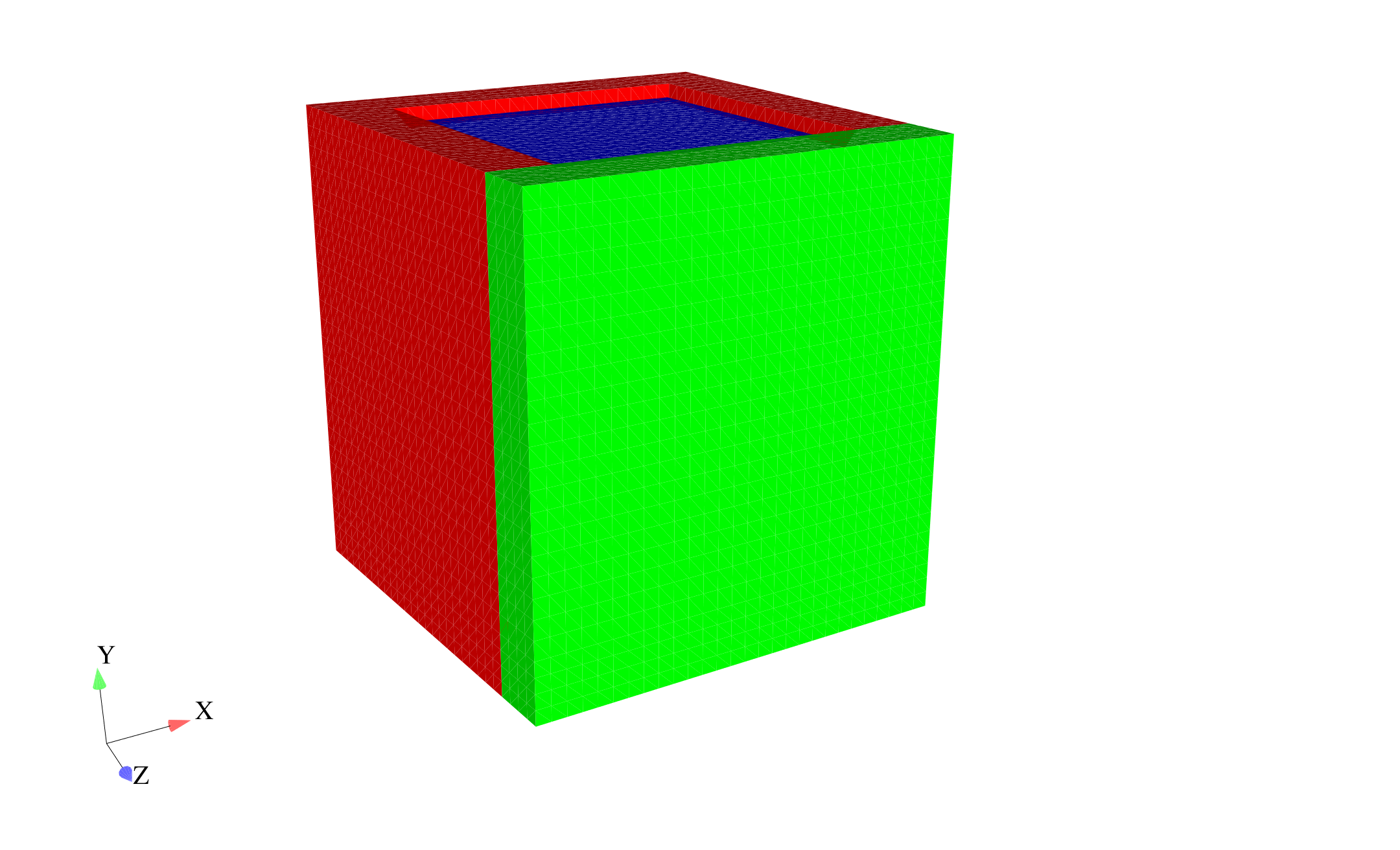

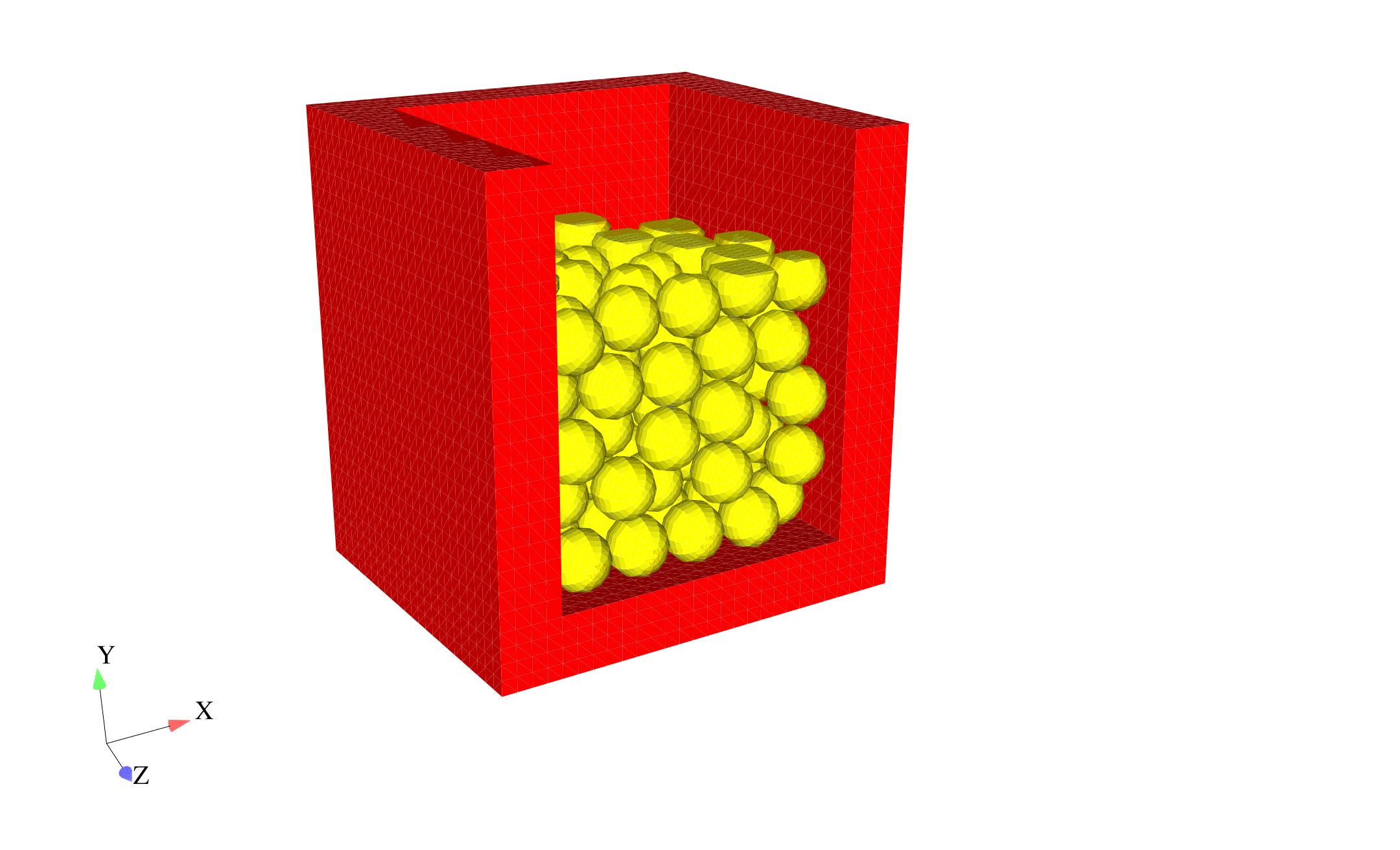

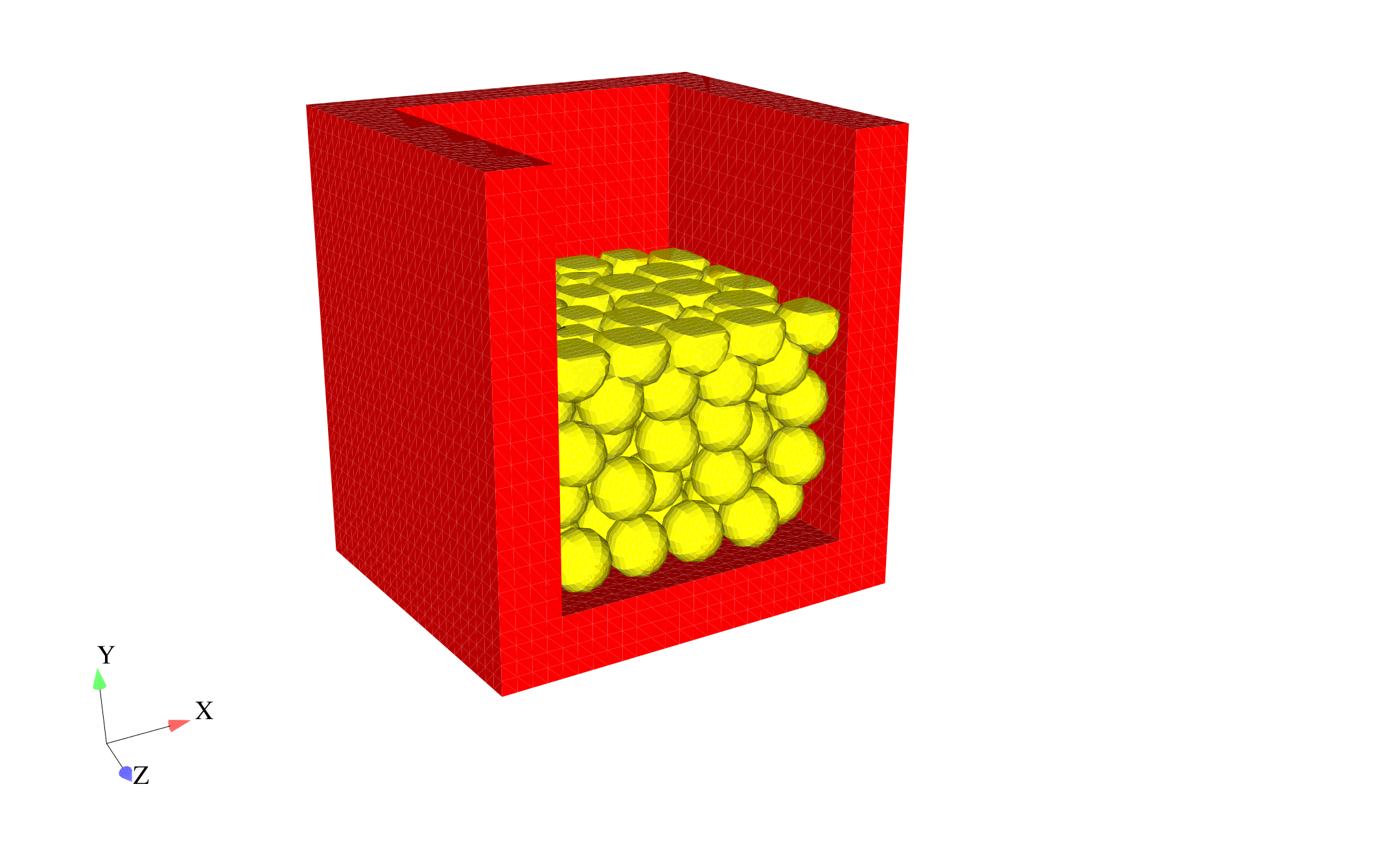

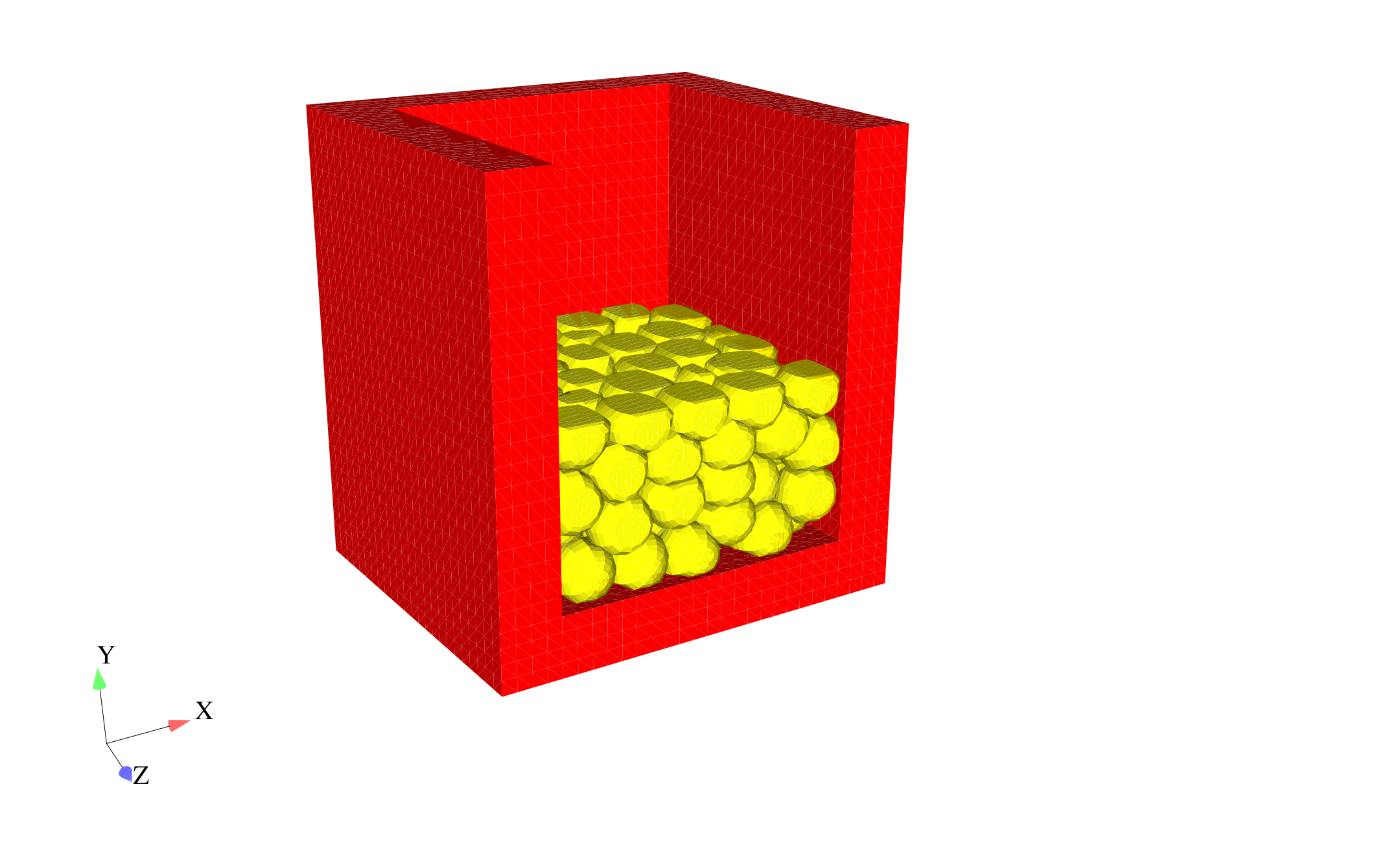

This chapter provides an example problem to illustrate the construction of an input file for an analysis. The example problem consists of 124 spheres made of lead enclosed in a steel box. The steel box has an open top into which a steel plate is placed (see Fig. 13.1). A prescribed velocity is then applied on the steel plate, pushing it into the box and crushing the spheres contained within using frictionless contact. This problem is a severe test for the contact algorithms as the spheres crush into a nearly solid block. See Fig. 13.2 for results of this problem.

Fig. 13.1 Mesh for example problem: (a) box (red and green surfaces) with plate in top (blue surface) and (b) mesh with blue and green surfaces removed to show internal spheres (yellow) with initial crush.

Fig. 13.2 Mesh with blue and green surfaces removed to show internal spheres (yellow) after initial crush shown in Fig. 13.1 (b).

The input file is described below, with comments to explain every few lines. Following the description, the full input file is listed again. Most of the key words in this example are all lowercase, which is different from the convention we have used to describe the command lines in this document. However, all the lowercase usage in the next example is an acceptable format in Presto.

The input file starts with a begin sierra statement (i.e., the first line of the SIERRA command block), as is required for all input files:

begin sierra crush_124_spheres

We now need to define the functions used with this problem. The boundary conditions require a function for the initial velocity, as follows:

begin function constant_velocity

type is piecewise linear

ordinate is velocity

abscissa is time

begin values

0.0 30.0

1.0 30.0

end values

end

To define the boundary conditions, we need to define the direction for the initial velocity – this is in the \(y\)-direction. We could also choose to specify the Y component for the initial condition, but this input file uses directions.

define direction y_axis with vector 0.0 1.0 0.0

Next we define the material models used for this analysis. This problem has two materials: steel for the box, and lead for the spheres. Both materials use the elastic-plastic material model (denoted as elastic_plastic).

begin material steel

density = 7871.966988

begin parameters for model elastic_plastic

youngs modulus = 1.999479615e+11

poissons ratio = 0.33333

yield stress = 275790291.7

hardening modulus = 275790291.7

beta = 1.0

end parameters for model elastic_plastic

end material steel

begin material lead

density = 11253.30062

begin parameters for model elastic_plastic

youngs modulus = 1.378951459e+10

poissons ratio = 0.44

yield stress = 13789514.59

hardening modulus = 0.0

beta = 1.0

end parameters for model elastic_plastic

end material lead

Now we define the finite element mesh. This includes specification of the file that contains the mesh, and a list of all the element blocks we will use from the mesh and the material associated with each block. The name of the file is crush_124_spheres.g. The specification of the database type is optional—ExodusII is the default. Currently, each element block must be defined individually. For this particular problem, all the spheres are the same element block. Each sphere is a distinct geometry entity, but all spheres constitute one element block in the Exodus II database. The three element blocks that make up the box and lid all reference the same material description. The material description is not repeated three times. The material description for steel appears once and is then referenced three times.

begin finite element model mesh1

Database Name = crush_124_spheres.g

Database Type = exodusII

begin parameters for block block_1

material = steel

model = elastic_plastic

end parameters for block block_1

begin parameters for block block_2

material = steel

model = elastic_plastic

end parameters for block block_2

begin parameters for block block_3

material = steel

model = elastic_plastic

end parameters for block block_3

begin parameters for block block_4

material = lead

model = elastic_plastic

end parameters for block block_4

end finite element model mesh1

As an alternative to referencing the material description for steel three times as done above, you could define multiple element blocks simultaneously on the same command line. Thus, the three element block specifications with the material steel could be consolidated into one, as follows:

begin parameters for block block_1 block_2 block_3

material = steel

model = elastic_plastic

end parameters for block block_1 block_2 block_3

At this point we have finished specifying physics-independent quantities. We now want to set up the Presto procedure and region, along with the time control command block. We start by defining the beginning of the procedure scope, the time control command block, and the beginning of the region scope. Only one time stepping block command block is needed for this analysis. The termination time is set to \(7 \times 10^{-4}\).

begin presto procedure Apst_Procedure

begin time control

begin time stepping block p1

start time = 0.0

begin parameters for presto region presto

time step scale factor = 1.0

time step increase factor = 2.0

step interval = 25

end parameters for presto region presto

end time stepping block p1

termination time = 7.0e-4

end time control

begin presto region presto

Next we associate the finite element model we defined above (mesh1) with this presto region.

use finite element model mesh1

Now we define the boundary conditions on the problem. We prescribe the velocity on the top surface of the box (nodelist_100) to crush the spheres, and we confine the bottom surface of the box (nodelist_200) not to move. Although we use node sets to define these boundary conditions, we could have used the corresponding side sets.

begin prescribed velocity

node set = nodelist_100

direction = y_axis

function = constant_velocity

scale factor = -1.0

end

begin fixed displacement

node set = nodelist_200

components = Y

end

Now we define the contact for this problem. For this problem, we want all four element blocks to be able to contact each other. In this case, we define the same contact characteristics for all interactions. Since no friction model is defined in the block below, the contact defaults to frictionless contact. (Numerous options exist to control the contact algorithm. The options you choose will affect contact algorithm efficiency and solution accuracy. See Section 8 to determine how to set input for the CONTACT DEFINITION command block to obtain the best level of efficiency and accuracy for your particular problem.)

begin contact definition

skin all blocks = on

begin interaction defaults

general contact = on

self contact = on

end

end

Now we define what variables we want in the results file and how often we want this file to be written. Here we request files written every \(7 \times 10^{-6}\) sec of analysis time. This will result in results output at one hundred time steps (plus the zero time step) since the termination time is set to \(7 \times 10^{-4}\) sec. The output file will be called crush_124_spheres.e, and it will be an Exodus II file (the database type command is optional; it defaults to ExodusII). The variables we are requesting are the displacements and external forces at the nodes, the rotated stresses for the elements, the time step increment, and the kinetic energy.

begin Results Output output_presto

Database Name = crush_124_spheres.e

Database Type = exodusII

At Time 0.0, Increment = 7.0e-6

nodal displacement as displ

nodal force_external as fext

element stress as stress

global KineticEnergy as KE

global timestep

end

Now we end the presto region, presto procedure, and sierra blocks to complete the input file.

end presto region presto

end presto procedure Apst_Procedure

end sierra crush_124_spheres

Here is the resulting full input file for this problem:

begin sierra crush_124_spheres

begin function constant_velocity

type is piecewise linear

ordinate is velocity

abscissa is time

begin values

0.0 30.0

1.0 30.0

end values

end function constant_velocity

define direction y_axis with vector 0.0 1.0 0.0

begin material steel

density = 7871.966988

begin parameters for model elastic_plastic

youngs modulus = 1.999479615e+11

poissons ratio = 0.33333

yield stress = 275790291.7

hardening modulus = 275790291.7

beta = 1.0

end parameters for model elastic_plastic

end material steel

begin material lead

density = 11253.30062

begin parameters for model elastic_plastic

youngs modulus = 1.378951459e+10

poissons ratio = 0.44

yield stress = 13789514.59

hardening modulus = 0.0

beta = 1.0

end parameters for model elastic_plastic

end material lead

begin finite element model mesh1

Database Name = crush_124_spheres.g

Database Type = exodusII

begin parameters for block block_1

material = steel

model = elastic_plastic

end parameters for block block_1

begin parameters for block block_2

material = steel

model = elastic_plastic

end parameters for block block_2

begin parameters for block block_3

material = steel

model = elastic_plastic

end parameters for block block_3

begin parameters for block block_4

material = lead

model = elastic_plastic

end parameters for block block_4

end finite element model mesh1

begin presto procedure Apst_Procedure

begin time control

begin time stepping block p1

start time = 0.0

begin parameters for presto region presto

time step scale factor = 1.0

time step increase factor = 2.0

step interval = 25

end parameters for presto region presto

end time stepping block p1

termination time = 7.0e-4

end time control

begin presto region presto

use finite element model mesh1

begin prescribed velocity

node set = nodelist_100

direction = y_axis

function = constant_velocity

scale factor = -1.0

end prescribed velocity

begin fixed displacement

node set = nodelist_200

components = Y

end fixed displacement

begin contact definition

skin all blocks = on

begin interaction defaults

general contact = on

self contact = on

end

end

begin Results Output output_presto

Database Name = crush_124_spheres.e

Database Type = exodusII

At Time 0.0, Increment = 7.0e-6

nodal displacement as displ

nodal force_external as fext

element stress as stress

global KineticEnergy as KE

global timestep

end results output output_presto

end presto region presto

end presto procedure Apst_Procedure

end sierra crush_124_spheres