4.4.4. Advective Bars

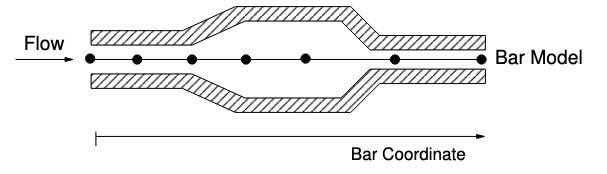

For problems in which convection heat transfer occurs at the surface the analyst must supply some judgment about the fluid flow that gives rise to convection. While this information is usually obtained by performing a coupled conjugate heat transfer analysis including details of the fluid flow, in many cases the cost of such an analysis may be prohibitive so the analyst must resort to alternative lower order models. One such model, the advective bar, can be applied to cases in which the convective heat transfer is driven by a flow internal to the body of interest as in Fig. 4.15. The bar model includes a simplified description of forced flow and flow section along the length of a one-dimensional discretization, where the advected flow is directly coupled with a corresponding energy equation. The bar temperatures define the far-field temperature distribution for convective heat transfer to the two or three-dimensional thermal solid model. The advantage gained by using the simplified velocity and temperature representation is that the velocity can be used to define both laminar and turbulent convective heat transfer appropriate to the specific problem using empirical heat transfer coefficients (see Correlation Heat Transfer Coefficient).

Fig. 4.15 Schematic of an advective bar

4.4.4.1. Using an Advective Bar as a Convective Flux BC

Use of the advective bar model requires that it be referenced by name in a

Convective Flux Boundary Condition along with the corresponding named Heat

Transfer Coefficient Correlation. Below shows a sample of an input deck that

uses an advective bar LIQUIDBAR with a corresponding heat transfer

correlation coefficient block CHANNEL to define a pair of convective flux

boundary conditions, CONV1 and CONV2.

BEGIN ARIA REGION MY_REGION

.

BEGIN ADVECTIVE BAR NETWORK LIQUIDBAR

.

END ADVECTIVE BAR NETWORK LIQUIDBAR

.

BEGIN HEAT TRANSFER CORRELATION COEFFICIENT CHANNEL

.

END HEAT TRANSFER CORRELATION COEFFICIENT CHANNEL

.

BEGIN CONVECTIVE FLUX BOUNDARY CONDITION CONV1

.

END CONVECTIVE FLUX BOUNDARY CONDITION CONV1

BEGIN CONVECTIVE FLUX BOUNDARY CONDITION CONV2

.

END CONVECTIVE FLUX BOUNDARY CONDITION CONV2

.

END

Advective Bar Equation discusses the

formulation of the advective bar equations.

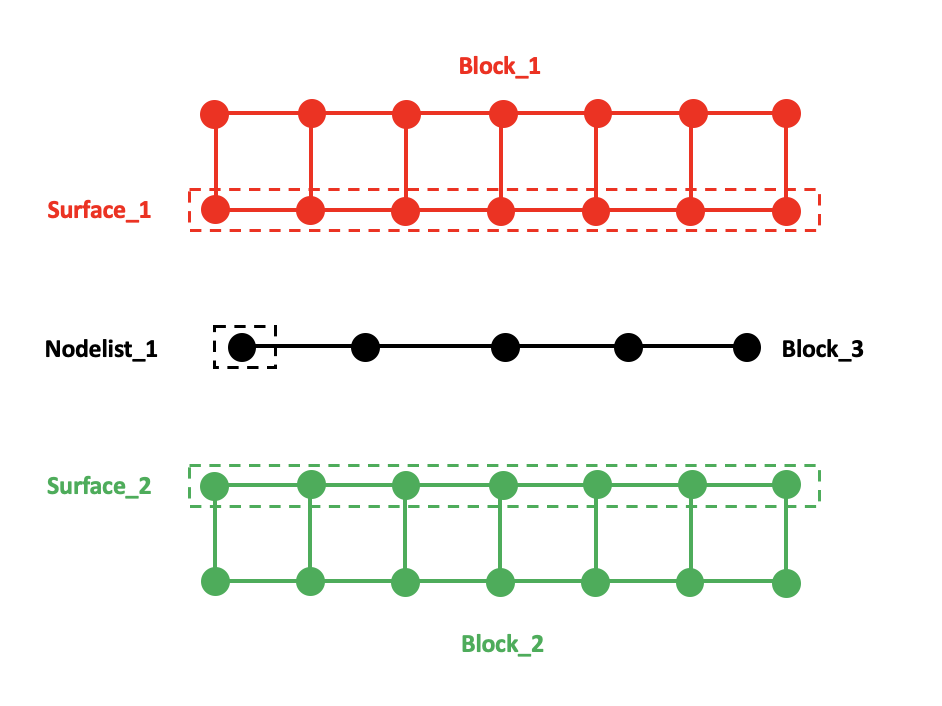

Fig. 4.16 shows a schematic of an advective bar

block, labeled Block_3 (black), set up between two volumetric blocks,

Block_1 (red) and Block_2 (green). The surfaces that are coupled to the

advective bar block are Surface_1 (boxed in the red dashed line) and

Surface_2 (boxed in the green dashed line), which belong to Block_1 and

Block_2 respectively. In addition, a nodelist is Nodelist_1 is defined

and contains only the left-most node in the advective bar block.

Fig. 4.16 Schematic of an advective bar block set up between two mesh blocks

Defining an advective bar requires various line commands in the aria material block as well as individual region-level commands. An example of declaring a typical advective bar block for the Schematic shown in Fig. 4.16 is given in the following. We first declare functions that will represent the wetted perimeter and bar area at the Sierra scope. We will also define an Aria material that will be assigned to the bar block:

BEGIN DEFINITION FOR FUNCTION AREA_FUNC

TYPE = PIECEWISE LINEAR

BEGIN VALUES

0.0 1.0

10.0 1.0

END VALUES

END DEFINITION FOR FUNCTION AREA_FUNC

BEGIN DEFINITION FOR FUNCTION WETTED_PERIM_FUNC

TYPE = PIECEWISE LINEAR

BEGIN VALUES

0.0 0.5

10.0 0.5

END VALUES

END DEFINITION FOR FUNCTION WETTED_PERIM_FUNC

BEGIN ARIA MATERIAL WATER

.

ADVECTION VELOCITY = BAR

BAR AREA = USER_FUNCTION NAME = AREA_FUNC X = BAR_COORDINATE

DENSITY = constant rho = 1000.0

.

END ARIA MATERIAL WATER

BEGIN FINITE ELEMENT MODEL FEM

.

USE MATERIAL WATER FOR BLOCK_3

.

END

The advection velocity for the bar material WATER must be defined as

ADVECTION VELOCITY = BAR. This advection velocity will be used for the bar

energy (and possibly momentum) equation. The advective bar command block along

with the bar energy equation are defined as follows:

BEGIN ARIA REGION MY_REGION

BEGIN EQUATION SYSTEM ENERGY

.

EQ ENERGY FOR TEMPERATURE ON BLOCK_3 USING Q1 WITH DIFF LUMPED_MASS ADV SUPG

ADVECTION VELOCITY FOR ENERGY = ADVECTION_VELOCITY

.

BEGIN ADVECTIVE BAR NETWORK LIQUIDBAR

.

ADD VOLUME BLOCK_3

MASS FLOW RATE AT NODELIST_1 = 100.0 # KG/SEC^2

FLUID DENSITY = 1000.0

FLOW CROSS SECTION AREA FUNCTION = AREA_FUNC

WETTED PERIMETER FUNCTION = WETTED_PERIM_FUNC

.

END ADVECTIVE BAR NETWORK LIQUIDBAR

.

END

END ARIA REGION MY_REGION

In the above, the advective bar area and density is defined under both the Aria

material WATER and advective bar network LIQUIDBAR. The reason why this

is done is discussed in Current Discrepancies with Advective Bars.

The nodelist block block_3 is added to the simulation as an advective bar.

For the above command block, the fluid density and fluid cross section area are

declared as constants. The leftmost node on the advective bar (nodelist_1)

is assigned a mass flow rate. A HEAT TRANSFER CORRELATION COEFFICIENT block is

declared under the same equation system (ENERGY for this example), labeled

CHANNEL:

BEGIN HEAT TRANSFER CORRELATION COEFFICIENT CHANNEL

LAMINAR CORRELATION = TYPE 1

TURBULENT CORRELATION = TYPE 74

TRANSITION REYNOLDS NUMBER = 3000.

COMPUTE REYNOLDS NUMBER

COMPUTE PRANDTL NUMBER

COMPUTE CHARACTERISTIC LENGTH MODEL = HYDRAULIC DIAMETER

COMPUTE FRICTION FACTOR MODEL = SMOOTH TUBE

COMPUTE ANNULUS DIAMETER RATIO

END

The HEAT TRANSFER CORRELATION COEFFICIENT defines a Nusselt Number () which

is used to compute the heat transfer correlation coefficient (Eq.

(3.80)). The above declaration uses a fully developed laminar flow

with an analytical

for the laminar region and a Gnielinski-type

correlation for annular flow with a friction factor in the turbulent regime.

The details of declaring the above command block can be found in Correlation Heat Transfer Coefficient. Convective boundary conditions, labeled

CONV1 and CONV2 are defined for surfaces surface_1 and

surface_2 in Fig. 4.16, respectively:

BEGIN CONVECTIVE FLUX BOUNDARY CONDITION CONV1

ADD SURFACE Surface_1

USE CORRELATION CONVECTION MODEL CHANNEL

USE ADVECTIVE BAR LIQUIDBAR

END CONVECTIVE FLUX BOUNDARY CONDITION CONV1

BEGIN CONVECTIVE FLUX BOUNDARY CONDITION CONV2

ADD SURFACE Surface_2

USE CORRELATION CONVECTION MODEL CHANNEL

USE ADVECTIVE BAR LIQUIDBAR

END CONVECTIVE FLUX BOUNDARY CONDITION CONV2

Alternatively, a single line command can be used in place of the above command block:

BC BAR_FLUX FOR ENERGY ON Surface_1 = GENERALIZED_NAT_CONV BAR=LIQUIDBAR HCORR = CHANNEL

BC BAR_FLUX FOR ENERGY ON Surface_2 = GENERALIZED_NAT_CONV BAR=LIQUIDBAR HCORR = CHANNEL

It should be noted that the above advective bar commands can also be coupled to

other energy EQ types, such as POROUS_ENTHALPY.

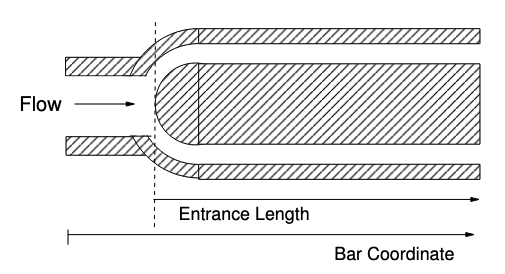

A bar model coordinate system facilitates user specification of the flow section properties. Here the bar coordinate system can be aligned with one of a Cartesian coordinate X,Y,Z directions. Optional use of an S coordinate system tied directly to the bar discretization enables modeling of flow along a circuitous path. Entrance length effects are supported for a limited number of empirical correlations. By default, influence of the entrance length effect is aligned with the bar model coordinates. Cases in which these effects are significant only over a portion of the flow can be modeled using an offset of the bar model coordinate (a schematic of this is shown in Fig. 4.17).

Fig. 4.17 Schematic of entrance length w.r.t bar coordinates

Advective Bar contains details about available commands for declaring advective bars.

Beta Capability

BAR MOMENTUM EQUATION is a beta feature and requires use of the –beta flag. This capability is not thoroughly tested and should be used with caution. Refer to Current Discrepancies with Advective Bars for proper usage.

4.4.4.2. Pressure Solve for Advective Bars

The pressure can be solved over the advective bar when requested. This is done by defining an equation system for the bar block:

BEGIN EQUATION SYSTEM Pressure

.

EQ BAR_MOMENTUM FOR PRESSURE ON BLOCK_3 USING Q1 WITH ADV SRC

SOURCE FOR BAR_MOMENTUM ON BLOCK_3 = MAJOR_LOSS

ADVECTION VELOCITY FOR BAR_MOMENTUM = ADVECTION_VELOCITY

BC DIRICHLET FOR PRESSURE ON NODELIST_1 = CONSTANT VALUE = 0.0

.

END

The individual terms ADV and SRC are defined in Advective Bar Pressure.

A MAJOR_LOSS source term is defined, which is the Darcy-Weisbach equation

for modeling head loss due to friction (Eq. (3.86)). Because

of this, we need to define a friction factor model in the Aria material block as

well:

BEGIN ARIA MATERIAL WATER

.

FRICTION FACTOR = HALAAND ROUGHNESS = 3.0E-5

.

END ARIA MATERIAL WATER

A list of Aria material friction factors can be found in Friction Factor.

It should be noted that these

friction factors are used separately from the HEAT TRANSFER CORRELATION COEFFICIENT

computed friction factors; their discrepancies are discussed in

Current Discrepancies with Advective Bars.

4.4.4.3. Current Discrepancies with Advective Bars

The following presents some discrepancies with defining advective bars that users should be aware of; these discrepancies will be resolved in time. Currently the advective bar command block is defined as follows within the Aria region scope:

BEGIN ADVECTIVE BAR NETWORK LIQUIDBAR

.

ADD VOLUME BLOCK_3

MASS FLOW RATE AT NODELIST_1 = 100.0 # KG/SEC^2

FLUID DENSITY = 1000.0

FLOW CROSS SECTIONAL AREA FUNCTION = AREA_FUNC

WETTED PERIMETER FUNCTION = WETTED_PERIM_FUNC

.

END ADVECTIVE BAR NETWORK LIQUIDBAR

The fluid density and the bar area must be repeated in the Aria materials block assigned to the bar:

BEGIN ARIA MATERIAL WATER

.

BAR AREA = USER_FUNCTION NAME = AREA_FUNC X = BAR_COORDINATE

DENSITY = constant rho = 1000.0

.

END ARIA MATERIAL WATER

BEGIN FINITE ELEMENT MODEL FEM

.

USE MATERIAL WATER FOR BLOCK_3

.

END

Each of these two duplicate parameters (bar area and density) are used for

separate purposes; the FLUID DENSITY and FLOW CROSS SECTIONAL AREA

FUNCTION under the advective bar command block are used for computing the

nodal bar velocity vector output (default name is BAR_VELOCITY) or

imposing a mass flow rate over the bar from a velocity boundary condition. The

Aria material (WATER for our example) density and bar area is used to

compute the velocity at the bar element integration points (Eq.

(3.79)), which is used as the advecting velocity (default

name is ADVECTION_VELOCITY) in the bar energy (and momentum) equation. The

nodal BAR_VELOCITY is currently automatically provided, whereas the

integration point ADVECTION_VELOCITY must be postprocessed for visualization

(see Postprocessing). For cases where these properties differ (and some other corner cases with

sharp angular turns in the bar block) the BAR_VELOCITY and the postprocessed

ADVECTION_VELOCITY may differ. For visualization, it is recommended that

the user request the magnitude of the bar velocity vector, BAR_VELOCITY_MAG,

which can be postprocessed as an expression.

Additionally, the FLOW CROSS SECTIONAL AREA FUNCTION function under the

advective bar command block can be used to compute the hydraulic diameter by

using the WETTED PERIMETER FUNCTION for the HEAT TRANSFER CORRELATION COEFFICIENT

command block.

For computing the pressure via the BAR_MOMENTUM equation, a friction factor

must be defined at the Aria material level if the MAJOR LOSS source term

accounting for viscous effects is used:

BEGIN ARIA MATERIAL WATER

.

FRICTION FACTOR = HALAAND ROUGHNESS = 3.0E-5

.

END ARIA MATERIAL WATER

In addition to this, a friction factor model is defined within HEAT TRANSFER CORRELATION COEFFICIENT

command blocks to compute a heat transfer coefficient:

BEGIN HEAT TRANSFER CORRELATION COEFFICIENT CHANNEL

.

COMPUTE FRICTION FACTOR MODEL = SMOOTH TUBE

.

END

It should be noted that these friction factors are used for separate

computations. In the current implementation of the BAR_MOMENTUM equation,

only the HALAAND friction factor model can be defined with the

MAJOR_LOSS source term; if any other friction factor model is defined along

with a friction factor model under the HEAT TRANSFER CORRELATION COEFFICIENT

command block, then a parsing error will occur with the message being related to

multiple expression handles being defined for the friction factor.