Sandia National Laboratories Centrifuge Complex strives to provide the most realistic flight simulation environments possible. Beyond the typical launch, re-entry and flight inertial loads that can be simulated, innovative solutions have been employed to combine controlled vibration, spin, thermal, shock, and other environments encountered in flight. Realistic combined environment testing is the optimal metric for quantifying flight component and system performance. The combination of ingenuity, experience, and equipment distinguishes this inertial testing facility from others. Its capabilities can meet a wide variety of customer needs, from a single load test to a series of highly instrumented, functional hardware performance tests.

Functional, structural and model validation testing is available on a 29-ft radius indoor centrifuge, 35-ft radius outdoor centrifuge, or smaller scale reconfigurable spin system. Payloads range from MEMS components to 16,000-pound, up to 1000-cubic-foot articles that may contain hazardous, radiological or explosive materials.

Measurement, Data, Communications and Connectivity

The Superfuge complex has exceptional measurement and connectivity infrastructure. Signals may be recorded on-board or passed through a variety of slip rings that include twisted shielded pair copper, high-current copper, coax, RF rotary joints, copper ethernet or fiber optic slip rings. Each centrifuge houses a ~20-cubic-foot instrumentation rack at the center of rotation with on-board 120V and 480V power circuits. A diverse set of on-board digitizers are available to record the most sensitive signals.

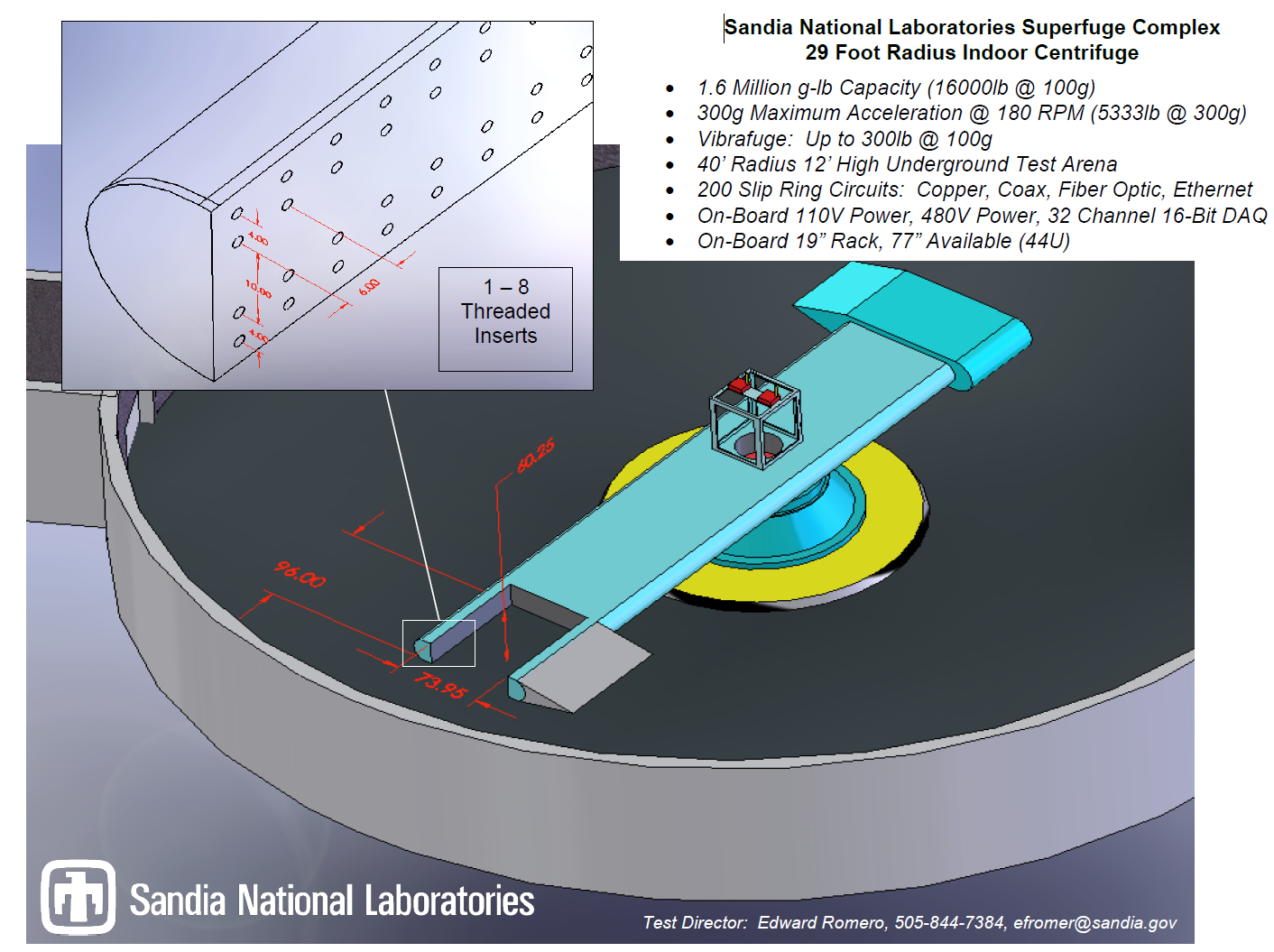

Indoor Centrifuge

The 29-foot-radius indoor centrifuge has a load capacity of 1.6 million g-pounds, making it one of the largest in the United States. This centrifuge is housed in an underground room that is 80 feet in diameter and 12 feet high, providing a relatively clean and temperature-controlled environment. It can accelerate a maximum payload of 16,000 pounds to 100 Gs, or lighter loads to 300 Gs. The maximum rotational speed of the centrifuge is 175 RPM. Typical payloads for the indoor centrifuge include:

- Satellite components

- Inertial sensors and switches

- Re-entry vehicles

- Geotechnical loads

- Rocket components

- Weapon components and systems

Outdoor Centrifuge

The 35-foot-radius outdoor centrifuge has a dynamic capacity of 450,000 g-pounds and is used primarily for hazardous test items. The outdoor centrifuge can explosively release test units for impact studies. It can accelerate a maximum payload of 10,000 pounds to 45 g or a 1,700-pound payload to 270 g. The maximum rotational speed of the centrifuge is 150 RPM. Typical payloads for the outdoor centrifuge include:

- Explosive payloads

- Oversized payloads that do not fit within the indoor centrifuge test arena

- Items to be released for impact testing

- Rocket motors for ignition testing

- 300 g Maximum Acceleration

- 16,000-lb Max Payload Capacity

- 1.6 Million g-lb Capacity

- 0.1 – 1.5 g/sec Onset and Decay rates

- 200 Copper, Coax, and Fiber Slip Rings

- 245 g Maximum Acceleration

- 10,000-lb Max Payload Capacity

- 450,000 g-lb Capacity

- 0.1 – 0.75 g/sec Onset and Decay rates

- 50 Copper, Coax, and Fiber Slip Rings

Vibrafuge

To more closely simulate real flight environments, an innovative approach was developed at Sandia’s Centrifuge complex to add controlled vibration to test units under inertial loading. This “Vibrafuge” capability has been proven to deliver combined environment testing over 100 g with up to 30 Grms controlled vibration up to 4,000 Hz for payloads up to 500 lbs. This new test capability has consistently demonstrated important synergistic effects from the more realistic combined environments, and provides the ability to determine margin assessment of system performance. Further advancement of flight simulation has been made through the development of a “Superfuge” system, capable of combining controlled acceleration, vibration and secondary axis spin for payloads up to 500 lbs.