Thermal property measurement capabilities have been developed to support thermal analyses. Most thermal properties (i.e., thermal conductivity and specific heat) are required as functions of temperature. Some of these properties vary a large amount within the temperature range we operate in (e.g., 0-1000°C or 32-1830°F). Data for most metals are available in the literature, but not so for many of the non-metallic materials we are concerned with, e.g., foam and insulating materials. Equipment used to measure thermal properties at the TTC include:

- Micron Model 300 blackbody calibration source, 200-1150°C

- Micron Model 330 blackbody calibration source, 300-1700°C

- Laser-flash device (FlashLine, Anter Corp.) for thermal diffusivity measurements

- Specialized 6-inch, 1-dimensional thermal diffusion setup. Measures thermal properties (conductivity, diffusivity) for materials with moderate to low thermal conductivity at temperatures between 25°C and 315°C

- Specialized setups to measure properties in 1-dimensional heat flow

Apparatus for thermal property measurements.

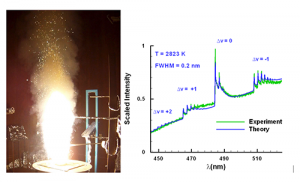

The advent of large-scale parallel computers and associated multi-physics computational simulations have driven the need to obtain detailed experimental information from fires for model development and validation. At the Thermal Test Complex (TTC), benchtop laser techniques such as CARS and PIV have been scaled up to full-scale burn experiments in the recent past. At present, other techniques involving emission spectroscopy and infrared (IR) imaging are being used to our advantage.

A quantum mechanical model of the rotational-vibrational frequencies for the band radiation of Aluminum Monoxide ("theory") fit to the data gathered from the rocket propellant plume pictured above ("experiment") to infer a temperature of 2823 Kelvin. The model fit was performed by Chris Parigger (UTSI) and the data was gathered and analyzed by Jonathan Height (NMSU).

Infrared imaging diagnostic. (The IR imaging diagnostics at the TTC are used in temperature, radiometric, and imaging modes. Here it is used to view structural changes in a test item while fully engulfed in a hydrocarbon fuel fire.)