DOE has awarded $25 million to Sandia to build, test and demonstrate a next-generation concentrating solar thermal power plant at the National Solar Thermal Test Facility.

The funding is part of the roughly $70 million, three-year-old DOE Generation 3 Concentrating Solar Power systems program, focusing on the development of next-generation concentrating solar systems that can achieve higher temperatures to accommodate advanced power cycles that are more efficient, thereby reducing the cost of the entire system.

Cliff Ho, project leader of the Sandia team responsible, said that the competition was unique compared to other DOE grants he’s worked on.

“It was sort of like an XPRIZE competition, with multiple teams competing to deliver a bold solution to a global problem,” Cliff said. “It was exciting.”

Conventional CSP systems use molten nitrate salt to transfer and store heat. However, molten salt decomposes at about 1,100 degrees F, and freezes at about 400 F, requiring expensive trace heating to prevent solidification.

In 2018, three teams were selected to compete using alternative liquid, gas and solid media pathways to design a next-generation CSP system that could economically and reliably deliver temperatures above 1,300 F for advanced power cycles. DOE funded other institutions for research and development in each of the three pathways.

Cliff’s team led the efforts to design a Gen 3 Particle Pilot Plant and spent the first two years reducing key component risks of the particle-based CSP system, developing a final design of the G3P3 system and performing technoeconomic analyses of a commercial-scale system.

DOE’s announcement said that, “solid particles provided the most promising pathway” to achieve the desired higher temperatures for CSP plants and to meet 2030 electricity cost targets of five cents per kilowatt hour. The primary factors that DOE considered were technical maturity of the heat-transfer pathway and key components, potential to achieve the 2030 cost targets, and the quality and likelihood of success of the proposed construction and test plan.

Cliff said that, following the successful design of G3P3, objectives for the next phase are to construct, commission, test and operate a multi-megawatt falling-particle receiver system that provides six hours of energy storage and heats a working fluid to greater than 1,300 F.

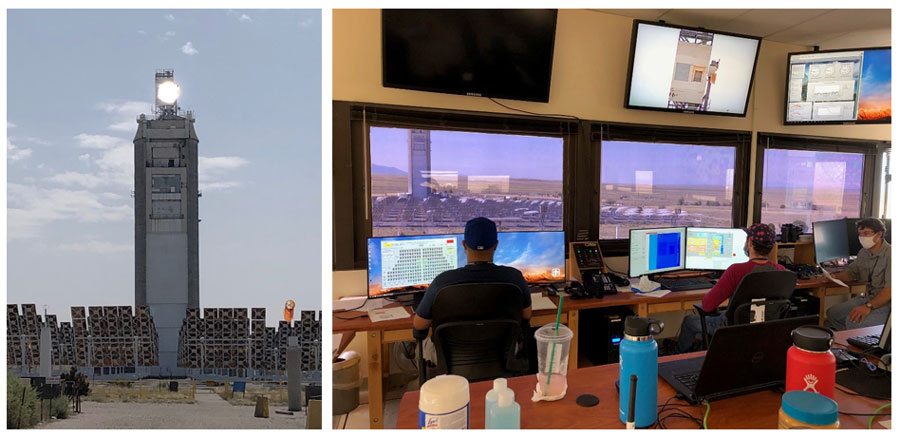

Cliff likened the G3P3 system to a gigantic hourglass filled with sand, except the particles are small, dark ceramic particles of roughly 0.3-0.4 millimeter that are manufactured for hydraulic fracking in the oil and gas industry. G3P3 will be built at the National Solar Thermal Test Facility next to the existing 200-foot tower so that it can use the existing heliostat field and infrastructure.

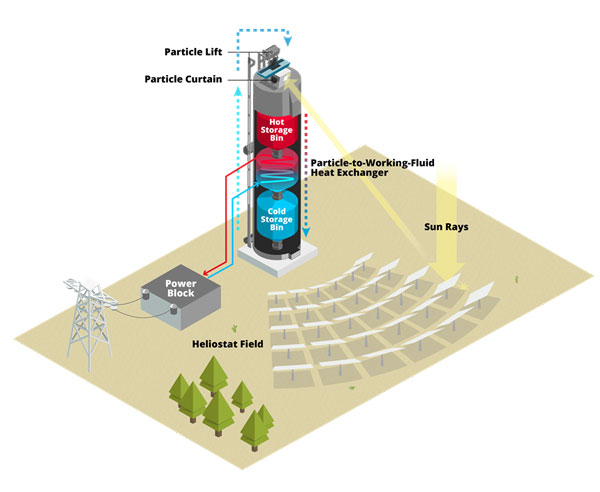

In the G3P3 system, particles fall through an open cavity on top of a tower and are irradiated by a beam of concentrated sunlight from a large field of heliostats — mirrors that track, reflect, and focus the sunlight like a magnifying glass to about 1000-2000 times the normal irradiance of the sun. The falling particles are heated rapidly to nearly 1,475 F and then collected in a storage bin for use on demand, even when the sun is not shining.

When energy is needed, particles are flowed through the bottom of the storage bin to a heat exchanger, where the particles heat supercritical carbon dioxide to more than 1,300 F. Supercritical carbon dioxide is a working fluid used in advanced sCO2 Brayton cycles being pursued by DOE and industry. The cooled particles are collected in a separate storage bin before being lifted back to the top of the system using a bucket elevator or skip hoist. In the vertically integrated tower, movement of particles throughout the system is driven entirely by gravity except for the particle lift, which reduces parasitic pumping costs associated with liquid- and gas-based CSP systems.

DOE Secretary Jennifer Granholm announced the $25 million award, during a “100% Clean” webinar. It is part of a $128 million package to national labs, universities and businesses to lower costs, improve performance and speed deployment of solar energy technologies, all aimed at achieving DOE’s ambitious decarbonization goals.

Key contributors to the project include Kevin Albrecht, Jeremy Sment, Brantley Mills, Nathan Schroeder, Henk Laubscher, Luis Garcia Maldonado, Francisco Alvarez, Scott Garcia, Rip Winckel and Scott Rowland. The technologists who supported testing were Daniel Ray, Kevin Good, Robert Crandell, Lam Banh, Benson Tso and Roger Buck.

As part of the G3P3 project, Cliff said that Sandia worked with its large network of international and domestic partners to reduce risks to the particle components and system features, including the receiver, storage bins, heat exchanger, particles, and system controls and integration.

The global effort included key partners in Australia —the Australian Solar Thermal Research Institute-Commonwealth Scientific and Industrial Research Organization, Australian National University and the University of Adelaide; Germany —German Aerospace Center, or DLR; France — CNRS-PROMES; Spain — Polytechnic University of Madrid; Italy — Magaldi Power; Canada — Solex Thermal Science; and Saudi Arabia — King Saud University and Saudi Electricity Co.

Cliff said that a number of U.S. industries and manufacturers, and research institutions, have participated in or provided services for G3P3, including: Allied Mineral Products; CARBO Ceramics; Bohannan Huston; Bridgers & Paxton; EPRI; Georgia Institute of Technology; Materials Handling Equipment; Matrix PDM; Olds Elevator; SolarDynamics; University of New Mexico; and Vacuum Process Engineering.

In addition to decarbonizing electricity production, Cliff said G3P3 can contribute to decarbonization in other areas.

“Developing particle-based CSP technologies provides a unique opportunity to reduce greenhouse gas emissions across multiple energy sectors to address the Biden administration goals for tackling climate change,” he said.

“These include industrial process heat, which contributes to nearly 20 percent of greenhouse gas emissions for manufacturing, chemical processing, and materials synthesis; electricity production, which contributes to nearly 30 percent of greenhouse gas emissions; and transportation fuels, which contributes to nearly 30 percent of emissions,” Cliff said. “CSP also offers the ability to provide economical, large-capacity, long-duration energy storage, which will be important with increasing penetration of intermittent renewables.”

More information about Sandia’s Concentrating Solar Power program is available at Generation 3 Concentrating Solar Power Systems, or visit the NSTTF.