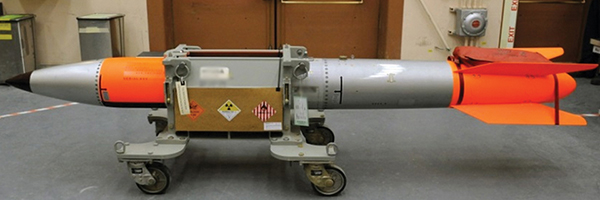

The newly configured B61 JTAM.

The JTA Modernization (JTAM) Project team developed a new Instrumentation System with a flight recorder as well as transmit capabilities for the collection of critical weapon performance data. This system provides an extensive increase in the flight-surveillance capability for the B61-3, 4, 7, and 11. The JTAM team delivered six system-level First Production Units in 2015. Project success is the culmination of more than four years of teamwork and dedication by many organizations, teams, and individuals. (2200) NW, NW

NNSA announced Oct. 23, 2014, that it had reached the halfway point in the production phase of the W76-1 Life Extension Program (LEP). The program involves engineers, scientists, and technicians from across the National Security Enterprise. The LEP first production unit was completed in September 2008 and the program remains on track to produce and deliver W76-1 warheads to the Navy to honor the commitment from NNSA to complete production later this decade. (400, 2200) NW, NW

The W88 ALT 370 DASO-26 Systems Team.

W88-0/Mk5 ALT 370 activities are proceeding and meeting critical program milestones, including critical flight tests and ground tests, design reviews, and program reviews. The data from ground and flight tests enable the design and development teams to verify full functionality and support ongoing development efforts. The successful development activities have been accomplished by a multidisciplinary team including Sandia, Los Alamos National Laboratory, Lockheed Martin Space Systems Corp., John Hopkins Applied Physics Laboratory, the Naval Surface Warfare Center Dahlgren Division, NNSA, and the US Navy’s Strategic Systems Programs Office. NW, NW

Mylar films are used in modern nuclear systems for pulse discharge capacitors to ensure high reliability with irreversible inoperability upon exposure to abnormal thermal environments. Sandia developed a chemical processing capability to impart radiation tolerance to Mylar films for the W88 Alt370 program. The production rate was improved from 300 feet per day to 13,000 feet, ensuring an ample supply of film will be available to meet program needs. Recent radiation effects testing demonstrated robustness, while multiple capacitor builds have demonstrated high reliability. (2600, 1800) NW, NW

Analysis, functional, normal, and abnormal environment testing was performed on eight safety mechanism products in their second development group for the B61-12 and W88 ALT 370. Simultaneous product realization for eight devices of this type has not been accomplished for more than 30 years at Sandia. This is being accomplished using high-performing teams that combine experienced leads, skilled technologists, and a large group of talented newer staff members who arrived at Sandia well trained to contribute immediately and who are excited about making an impact. (2600, 0400, 2900, 1800, 1500) NW, NW

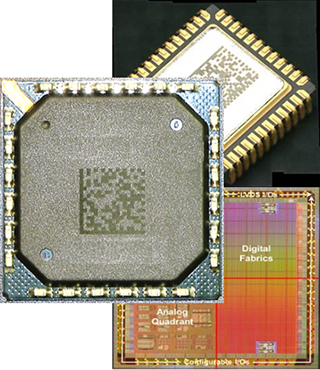

Examples of a few of the ASIC products and an ASIC design implementation.

FY15 saw the initiation of Sandia’s largest production effort for War Reserve (WR) Mark Quality (MQ) Application Specific Integrated Circuits (ASICs) to be delivered to the B61-12 LEP, W88-ALT-370 and W87 Mk21 Fuze programs. Multiple ASICs are used in these systems, and hundreds of ASICs were delivered to Major Components (MCs) in FY15 for design maturation and product qualification efforts. This accomplishment is the culmination of significant effort by teams across 1700 and across Sandia, including 1300, 1800, 2100, 2200, 2500, 2600, 5300, 8200. NW, NW PMU

In FY15, the Electronic Neutron Generator Product Realization Team completed its planned development and problem-solving builds on schedule and with yields higher than expected. Reasons for the high yields include lowering the high-level risks (high voltage breakdowns and loss of bias) through problem-solving activities that led to the implementation of effective countermeasures, and building the units on the production floor, leveraging as much as possible the manufacturing infrastructure early in the development phase. (2700, 2600, 400) NW, NW

Sandia partnered with the National Security Campus to produce development hardware using metal-based additive manufacturing. Testing results have proven that the printed part can withstand a 150-percent increase in the impact load over the corresponding machined and welded design. This is due to topology optimization that is only possible to produce through additive manufacturing. The team is now engaged in fully understanding the material properties and manufacturing process variability to determine if printed parts can be qualified and accepted as diamond-stamped product. (2900, 2100, 1800, NSC) NW, NW

The Zeiss Prismo Ultra, with a measuring volume of 900 mm x 1300 mm x 650 mm, is capable of accuracies of 0.4 +L/500 um.

To support increasing demands for lower measurement uncertainties associated with the calibration of dimensional gauges and fixtures for Sandia’s Neutron Generator Enterprise, Mechanical Calibration has acquired a high-accuracy (i.e. sub-micrometer) coordinate-measuring machine. The fully numerically controlled machine is equipped with both a tactile and non-contact optical probe sensor for inspection of components using 3-D CAD models. High-speed active scanning data collection along with computer-aided accuracy optimizes precision measurements. To achieve high accuracies, the system is equipped with low-expansion coefficient scales and elastomer vibration air damping. (2500) NW, NW

The NNSA-wide enterprise modeling and analysis consortium (EMAC) team executed the Sandia-developed Complexity Options, Risk and Evaluation (SCORE) model and process, used again this year by NNSA’s Office of Budget Execution, Cost and Financial Management as a basis for cost model calculation and incorporation in the 2017 Stockpile Stewardship and Management Plan. Similarly, EMAC used the Sandia-developed tritium supply and demand model to enhance integration within NNSA and the design agencies and production agencies supporting both the NA-12 Tritium Change Control Board and the NA-19 Tritium Supply Program. (200) NW, NW

Launch of the Minuteman III Intercontinental Ballistic Missile from Vandenberg Air Force Base, carrying an instrumented W78 Joint Test Assembly for the W78/Mk12A Extended Range Instrumented Flight Test.

The first W78/Mk12a Extended Range Instrumented Flight Test was launched from Vandenberg AFB on March 23, 2015. This was the longest flight distance ever flown by a W78/Mk12a instrumented flight vehicle. The system performed nominally and the test was scored a success. This important test provided new performance information in stressing environments, improving our technical basis. This is especially important given the extended deployment period of the W78. The Air Force, Navy, and NNSA and its complex all contributed to this successful mission. (2200, 0400) NW, NW