Sandia researchers want airports, border checkpoints, and other security areas to be able to detect homemade explosives made with hydrogen peroxide without also singling out people whose toothpaste happens to contain peroxide.

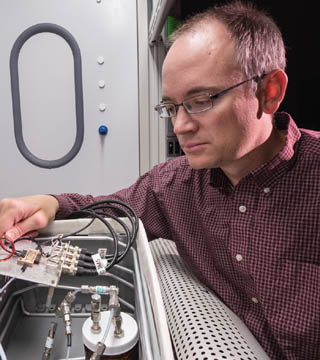

That’s part of the challenge in developing a portable sensor to detect a common homemade explosive called a FOx (fuel/oxidizer) mixture, made by mixing hydrogen peroxide with fuels, says Chris Brotherton (6633). The detector must be able to spot hydrogen peroxide in concentrations that don’t also raise suspicions about common peroxide-containing products.

“Hydrogen peroxide explosives are a challenge because they are dangerous, but there are so many personal hygiene products that have hydrogen peroxide in them that the false positive rate is very high,” says Chris, principal investigator for an Early Career Laboratory Directed Research and Development (LDRD) project on chemiresponsive sensors to detect a common homemade explosive.

Hydrogen peroxide is found in everyday products ranging from soap, toothpaste, and hair color to laundry bleach, carpet cleaners, and stain removers.

The LDRD proved a sensor could identify relatively high concentrations of hydrogen peroxide and

differentiate that from a common interfering substance such as water, Chris says. The next step, he says, will be to work with an industrial partner to design an overall system that is faster and can be mass produced.

His work is built on field-structured chemiresistor technology developed at Sandia more than a decade ago by James Martin (1114) and Doug Read (1716). Chemiresistors are resistance-based sensors for volatile organic compounds. James and Doug, who have published several papers on their work, developed a significantly improved material that allows sensors’ response range and sensitivity to be tailored.

Finding the right polymer

Chris also faced the problem of coming up with a way to distinguish between hydrogen peroxide and water, which can exhibit similar behavior in chemiresistors. The key was choosing certain molecules in a polymer matrix, suggested by his technical mentor, polymer chemistry expert David Wheeler (1714). When exposed to peroxide, those molecules react in a different way than when exposed to water.

The idea is to engineer the polymer to be as similar to the target material as possible, relying on the undergraduate rule that like dissolves like. For example, David says, if the target is a substance that’s not very polar, you’d choose a polymer with nonpolar groups. If the target had a lot of polarity, like water does, you’d develop polymers that could hydrogen-bond with water.

The tiny sensor incorporates the polymer and chains of miniscule conductive metal beads. The polymer reacts when it’s exposed to the substance being analyzed.

“We tried to include specific molecules that would react with the peroxides,” Chris says.

Exposure to water also changes the polymer’s properties, but it returns to its previous state once the water is removed. Exposing the polymer to concentrated hydrogen peroxide, however, irreversibly changes it.

“So once you’ve done this to the polymer you’ve permanently changed it,” Chris says. “Instead of being a reusable sensor, it’s more of a disposable dosimeter.”

It’s also a detector that doesn’t react to toothpaste and other common peroxide products, he says.

Detector has other potential uses

Manager Paul Smith (6633) says the sensor has other potential uses, such as monitoring underground water, looking for plumes of contamination, or monitoring industrial processes.

Chris cautions that it’s not a silver bullet, but says the technology has shown good results.

“It has some challenges that have to be overcome, but we think it’s worth pursuing to the next level,” he says.

Researchers need to reduce the chemical reaction time so the sensor doesn’t take too long to be useful at a checkpoint, Chris says. The detector also must be incorporated into a larger unit that includes equipment to gather a sample for analysis.

The sensor doesn’t need a significant amount of electronic processing or power supplies, Chris says, adding, “This technology would be easier to integrate into other detection technologies without impacting them too significantly.”

It wouldn’t have to be a large unit. Various detectors on the market today are about the size of a small handheld vacuum cleaner, Paul says.

Getting the air to the detector

The support equipment would suck up a sample of air and the detector would test it.

“You’d need to know where the fumes were coming from,” Chris says. “It’s not enough to open up the whole room and suck in all the air and say, ‘There are peroxides somewhere in here, watch out.’ What we’d like to do is go up and down luggage, or be next to some sort of industrial process so we know this is most likely the source and it’s above a level we care about.”

Although a detector package could target a single type of vapor, a manufacturer could add it to a unit to detect several substances. That way a checkpoint could have one sensing system rather than separate units for every material of concern, Chris suggests.

“Maybe it’s a suite of sensors to try to hedge our bets,” he says. “We’ve focused on a very specific application, but there’s no reason you couldn’t take this concept and use different polymers and look at multiple substances at the same time.”