What if a nuclear reactor melted down, exposing the nearby population to dangerous levels of radiation? That scenario has been on everyone’s mind since Japan’s devastating 9.0 earthquake and subsequent tsunami crippled the Fukushima Daiichi nuclear plant.

“The trouble with radiation sickness is that the symptoms are often latent and don’t appear for days, weeks, or even months,” says Greg Sommer (8621). “But data clearly shows that if you can start treatment within the first 24 hours of exposure, the prognosis for recovery goes up significantly.”

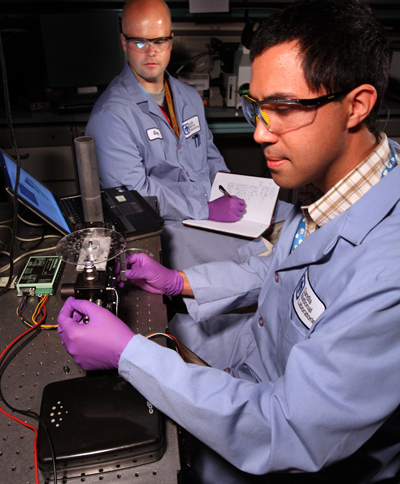

Radiation exposure leaves a clear signature in a victim’s blood, but reading that signature is time- and labor-intensive, far outside the scope of an emergency response. For the past year and a half, Greg has been working on a Laboratory Directed Research and Development (LDRD) project to create a handheld radiation biodosimetry device to answer that need.

“In a mass exposure, you can’t rely on hospitals and clinics for screening because demand will quickly overwhelm their capacity,” he says. “The goal is to put a drop of blood into the device without any pretreatment — it could come straight from someone’s finger — and have an answer about their level of exposure within 15 minutes. Then you can target therapeutics to the people who really need them.”

The original LDRD project set out to develop a portable device to rapidly screen blood for a panel of protein biomarkers, leveraging Sandia’s expertise in point-of-care clinical diagnostics and protein screening. That scope changed after Greg began working with colleagues at the Armed Forces Radiobiology Research Institute (AFRRI), a DoD laboratory, who have developed the panel through 30 years of research on radiation signatures in blood using animal models.

“They asked us to bring in a hematology component to do a white blood cell count,” he says. “A good white blood cell count combined with the protein measurement yields a very accurate dose assessment. This threw a monkey wrench into our project, but it’s a worthy challenge. Point-of-care hematology is a powerful tool.”

Meeting two daunting challenges — adapting hematology to a portable format and then combining methods for protein detection and white blood cell counting onto a single device — required a whole new approach, something quite different from the standard microfluidics-based lab-on-a-chip used in many of Sandia’s portable diagnostic tools. The answer to both challenges, it turns out, was centrifugal force.

Centrifugal force is key

Postdoc Ulrich Schaff (8621), who did his doctoral research at a University of California, Davis lab studying inflammation and white blood cells, turned to the concept of lab-on-a-disk, which uses the centrifugal force generated by a spinning disk to manipulate a sample.

“The idea was to put a preparatory centrifuge in the device to do blood counts directly from the separation technique,” Ulrich says. “We’ve combined operations that you really can only do on a disk. If you just try to miniaturize benchtop preparation methods, you wind up with a very complex network of channels and storage containers. Using separation principles for these steps greatly simplifies the design.”

The lab-on-a-disk prototype that Greg and Ulrich developed is deceptively simple, in that it hides their meticulous work developing disk-based assays and the mechanics of the disk itself. First the sample, a drop of blood, is routed to the center of the disk, which is then spun slowly to enable capillary action to route the sample through channels into different assay regions. The sample is mixed with pellets to capture the proteins and fluorescent tags that enable identification. A faster spin of the disk sends the different samples to the bottom of the channels for analysis.

The beauty of the device, says Greg, is that it is simple and ubiquitous.

“All you need to run the disk is a motor and a laser, both found in any CD player,” he says.

Designed to run on existing infrastructure

That simplicity was quite clear as they developed the disk using a Dremel tool as a motor and a hairdryer to simulate a heating element. They read the results under a microscope, a step that will be automated using a laser to produce a digital readout.

Ulrich and Greg published initial results in Clinical Chemistry (Vol 57, Issue 5, pp 753-761, 2011) demonstrating protein separation using the lab-on-a-disk. A follow-up publication is planned to show that the device can also perform white blood cell counts.

They now are using DoD blood samples to validate the device’s analytics against “gold standard” benchtop methods. The team hopes that getting the lab-on-a-disk radiation biodosimeter into the field won’t be difficult, given its overall simplicity.

“The system is being designed to run on existing infrastructure, so there wouldn’t be the typical barriers of capital investment or training,” says Greg. “With the hematology component, this device also has potential for applications far beyond radiation biodosimetry, such as biodefense, emerging infectious diseases, cancer, and HIV treatment and research.”