Microencapsulation isn’t a new technology, but it’s always finding new applications. Familiar uses include the scratch-and-sniff perfume ads in magazines, certain time-release pharmaceuticals, and (perhaps mostly for an older generation) carbonless copy paper. Now Sandia’s resident microencapsulation expert, Duane Schneider (2453), is working with a local Albuquerque company to use microencapsulation technology in a novel self-warming hand and body lotion.

Microencapsulation, as its name suggests, is the creation of a tiny capsule (or, in practice, lots of tiny capsules), usually just microns in diameter, containing a particular material. In practice, microencapsulation entails placing a spherical shell composed of a synthetic or natural polymer completely around another chemical. That shell delays or slows the release of the core material. When the polymer shell dissolves or is ruptured by pressure, the material it encapsulates is released.

In addition to the familiar uses noted above, microcapsules have found uses in the pharmaceutical, agricultural, cosmetic, and food industries and have been used to encapsulate oils, aqueous solutions, alcohols, and various solids.

Duane didn’t start out as the microencapsulation go-to guy at Sandia, but a need arose and he stepped forward to fill it, learning everything he could about the subject, which can be as much an art as a science. Microencapsulation work is but one aspect of Duane’s job in the Organic Materials department — he also supports a variety of nuclear weapon, alternative energy, and nanoscience programs as a chemical technologist. Over the years he’s developed microencapsulation solutions for a number of critical national security-related projects. For example, his microencapsulation work has found its way into Sandia technology designed to detect explosive materials.

Sandia researchers aren’t the only ones who’ve come knocking on Duane’s door. Not long ago, Kevin Mallory, owner and president of Formulab, an Albuquerque-based contract manufacturer of personal care products, had an idea: Why not create a lotion that uses an exothermic chemical reaction to create a slight warmth when rubbed on the hands or body? Mallory, a chemist himself, knew the underlying chemistry was sound. The challenge was: How do you keep the chemicals separate in the lotion until you want the warmth? There were options: You could bottle the ingredients separately, the way epoxy glues are packaged. A more desirable solution, Mallory thought, would be to use a microencapsulation technique that would allow both active components of the lotion to live together in the same bottle. One or both key ingredients would be encapsulated; only when gently rubbed — as when applying a lotion — would the encapsulating polymer rupture, releasing the active ingredients inside and allowing the chemicals to combine in a mild exothermic reaction.

Sport cream and arthritis formula lotions create a sensation of heat; in the product or line of products Mallory envisioned, the exothermic reaction would produce real heat, the amount of heat based on the chemicals used and the concentration of those chemicals.

Mallory was convinced he had a winning idea but didn’t have the microencapsulation expertise to prove out the concept himself. That’s when he turned to Sandia and its Small Business Assistance (NMSBA) program. The folks in the program linked up Mallory with Duane and Duane’s boss, Mike Kelly. The three talked about Mallory’s idea and what he’d like to accomplish. Duane and Mike agreed that Sandia could help, and Mallory and Duane began working together.

There are several ways to microencapsulate materials, some mechanical and some chemical, and a number of factors to consider when deciding which approach to take.

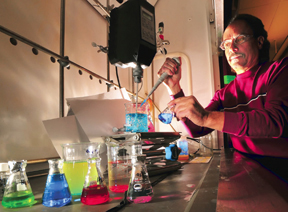

When Duane analyzed what Formulab wanted to do, he decided to use a so-called polymer-polymer incompatibility method to microencapsulate the materials. In this process the aqueous core and an organic solvent that contains the dissolved polymer shell material are stirred into an emulsion. The stirring causes the aqueous phase to form tiny beads. A second polymer, one that is known to be more soluble in the organic solvent, is then introduced to the emulsion. These two polymers are incompatible in the solvent; that incompatibility causes the intended shell polymer to form a third phase that wraps around the aqueous core material. The shell polymer can then be solidified by means of the addition of a chemical catalyst and/or UV light exposure.

As Duane moved ahead on the project, he invited Mallory to come and observe the work in the Center for Integrated Nanotechnologies (CINT) facility on Eubank Boulevard, just outside the Eubank Gate. At CINT, Duane supports nanoscience research in the laboratory of Dale Huber (1132).

Mallory says his interaction with Sandia was invaluable. “This was like a crash course in microencapsulation; it really accelerated our learning curve. It helped us a tremendous amount,” he says.

Mallory characterizes the Sandia relationship as “absolutely fantastic” and, speaking of the NMSBA program says, “I’ve been thinking about how lucky I am to live in a community where this kind of help is available.”

Ultimately, the project ended on a positive note.

“We were able to show that we could microencapsulate the materials,” Duane says, adding that a follow-on agreement with Formulab may involve looking at some alternative materials.

“I think it’s fair to say,” Duane adds, “that Kevin [Mallory] found that what he was looking for wasn’t going to be as easy as he thought it might be, but we did show that it was doable.”

The Sandia-Formulab relationship was established to develop a proof of concept and that was done. Between that lab bench project and a commercial product there are still plenty of hurdles, but that’s the case with every product on the shelves. Kevin Mallory’s concept for a self-warming lotion is now one step closer to realization thanks in no small measure to the expertise of a Sandian who stepped to the plate years ago to fill a need when the Labs called.