Hydrogen may be the lightest element, but it’s a heavy hitter when it comes to clean energy.

President George W. Bush and California Gov. Arnold Schwarzenegger have both sung its praises as a potential energy carrier. “Hydrogen highways” are planned worldwide, in Japan, Canada, Scandinavia, and naturally, California.

For all its promise, the use of hydrogen as an energy source still poses technical hurdles. Hydrogen diffuses readily into many structural materials. When this happens, the hydrogen alters the properties of the material, which can lead to degradation and, ultimately, fracturing.

Unique aspect of hydrogen

“This is a unique aspect of hydrogen,” says materials scientist Brian Somerday (8758). “Because of its small size, it can readily diffuse into materials at room temperature. Other gas species can promote embrittlement of structural materials, but the mobility of hydrogen at room temperature makes it unique as an embrittling agent.”

This easy absorption is a good thing when the goal is to store hydrogen in a metal hydride for onboard fuel storage. But when looking at the fuel tank or anything else that might contain hydrogen, such as storage tanks and piping, embrittlement increases the potential for leaks.

Materials scientists have been working on hydrogen embrittlement since long before the term “hydrogen highway” joined the vernacular. “This is not a new phenomenon, but one that has been studied for decades,” says Brian.

Brian, in fact, was hired by Sandia 10 years ago to work on hydrogen embrittlement in relation to gas transfer systems. While his work now also supports the presidential Hydrogen Fuel Initiative, the basic science hasn’t changed.

“By measuring the structural properties of the materials, quantifying the degree by which they will degrade when stressed in hydrogen, and simulating the cracks that occur in the structural material, we can minimize the impact of embrittlement through proper design” says Brian. “The ultimate goal is to eliminate the possibility of embrittlement altogether.”

Guidance for storing hydrogen

This level of understanding will help provide guidance for storing hydrogen for automotive purposes — whether in an onboard fuel tank, storage tank at a refueling station, or piping that hydrogen might flow through between the two. As Brian explains, the program is interested in anything that might come in contact with high-pressure hydrogen. The results of Sandia’s research will facilitate decisions such as what structural materials to use for hydrogen storage and the lifespan of such materials.

The research Brian is leading focuses on low-cost steels, aluminum alloys, and stainless steel. “Materials have to fit the structural requirements, as well as other design constraints such as cost and weight,” he says. “There is a lot of interest in low-cost, high-strength materials.”

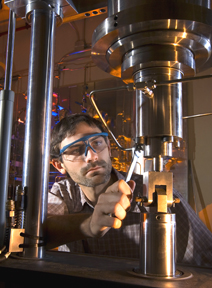

In the lab, various materials, in a range of specimen geometries, are subjected to high-pressure hydrogen in situ. A key aspect is looking at what happens to preexisting cracks in the materials. “An important interaction happens between hydrogen gas and cracks that are under stress, as the hydrogen concentrates in areas of high stress,” says Brian.

“The important combination of features in this system is the ability to subject material specimens to dynamic loads in hydrogen gas pressures up to 138 MPa (20,000 psi). There are other systems that can apply dynamic loading on material specimens exposed to hydrogen gas, but only three with this pressure capacity,” Brian says. Only two other laboratories in the world have this capability, one in Japan and the other in the United Kingdom.

Brian’s expertise on the subject has not gone unnoticed. This summer, Brian will serve on the faculty of European Summer School on Hydrogen Safety, held at the University of Ulster (Belfast, UK). He’ll teach a two-part course on “Hydrogen Effects in Materials.”

Brian will be joined by Jeff LaChance (6761), who will teach a course on quantitative risk assessment (QRA) for the hydrogen infrastructure. His course will cover the basic concepts of risk and the requirement and process for performing QRAs on different types of hydrogen facilities. For Jeff, this is a case of “teach what you know,” as he leads Sandia’s work on QRAs for the hydrogen infrastructure.

“In addition to performing QRAs, we also use the results to risk-inform the requirements of hydrogen codes and standards. The concept of risk-informing utilizes risk information, along with deterministic considerations and other factors deemed important by the code developers when they establish the code requirements. It also helps focus the requirements on factors important to safety, and in some cases, identifies new requirements that may not have been considered using other code development approaches. The public can be assured that a facility that meets existing and future risk-informed code and standards requirements is safe,” he explains.

Brian is in for a busy summer, as he’s also co-organizing the 7th International Hydrogen Conference, scheduled to take place in September at Grand Teton National Park in Wyoming. The conference, which began in 1973, will emphasize the effects of hydrogen on structural materials with a specific focus on its use as fuel.