In a development that could significantly speed up the process of destroying old chemical munitions,

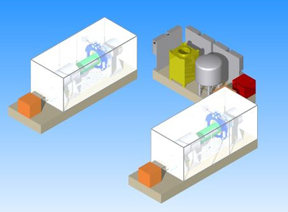

Sandia engineers have proposed an enhanced version of the Explosive Destruction System, a transportable device widely used by the US Army to safely neutralize and discard large quantities of chemical warfare material recovered from test ranges, burial sites, and other locations.

A Sandia white paper describes the High Throughput Explosive Destruction System (HTEDS) and addresses a vital need for remediation systems to destroy recovered munitions at a substantially faster rate than can be done with current methods. This need was highlighted in a recent report by the National Research Council.

The HTEDS, say Sandia engineers, could also be used at sites such as the Pueblo Chemical Depot in Colorado and the Blue Grass Army Depot near Richmond, Ky., to treat some stockpile munitions that require special handling, particularly those that have started leaking and are now stored in secondary overpack containers.

EDS: proven, effective technology

Sandia’s HTEDS concept builds upon the Army’s Explosive Destruction System (EDS), which was designed by Sandia in the late 1990s to provide a self-contained, transportable capability to remediate small volumes of nonstockpile chemical munitions at recovery sites. The EDS has proven to be a flexible, capable, effective system and has achieved wide acceptance by public and regulatory agencies. Among other successes, the EDS destroyed sarin nerve agent-filled bomblets at the Rocky Mountain Arsenal near Denver and mustard-filled 75-mm projectiles at Spring Valley in Washington, DC.

A 2005 study by Sandia also confirmed EDS’ ability to safely destroy biological agents.

The Non-Stockpile Chemical Materiel Project’s current inventory of remediation systems, says Brent Haroldsen (8125), includes the EDS and other technologies. Though the systems have performed well, they were all designed to handle only very few items at a time.

Sandia’s proposed HTEDS promises to optimize already proven EDS technology to process up to 60 munitions daily, increase the size of the munitions that can be treated, and make improvements to instrumentation and automation. The transportability of the EDS, as well as its proven explosives access and treatment processes that have achieved public and regulatory acceptance, would be maintained with the HTEDS. The proposed HTEDS, says Brent, could be at the prototype stage and ready for testing as early as 2010.

HTEDS could play a role

The EDS was designed for recovered nonstockpile munitions but is also well suited for handling unusual stockpile munitions. Although these munitions constitute only a small fraction of the stockpile, they require special handling, which can slow the operation of the treatment facility.

HTEDS would integrate well with the large-scale pilot plants that are being built under the Assembled Chemical Weapons Alternatives (ACWA) program, said Sandia’s Bill Replogle, manager of the lab’s Advanced Systems Deployment department. “It uses similar non-incineration treatment technology and is specifically designed to handle off-normal munitions that would be the most difficult to handle in the pilot facility,” he said. “The HTEDS would be particularly effective at treating leaking M55 rockets since both the chemical agent and the rocket motor can be destroyed without first removing the rocket from the secondary container,” said Haroldsen. A separate Sandia white paper addresses treatment of these particular munitions.

A high-throughput EDS, Sandia engineers say, could be designed, built, and ready for testing in roughly two years.