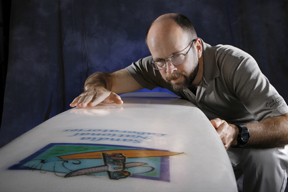

Even though LeRoy Whinnery (8778) has been described by ESPN’s magazine as an "avid surfer," he was not in San Diego last week to ride the waves. Instead, he was at the Federal Laboratory Consortium (FLC) Far West and Mid-continent Regional Meeting to accept a 2007 Notable Technology Development Award for TufFoam(tm).

"I am very honored that the efforts of the TufFoam team have been recognized," he says. "It has been a lot of work achieving our current level of technical understanding of TufFoam, as well as protecting the intellectual property and dealing with media and licensing requests. I am fortunate to be part of a great team where people work well together and help each other."

Greener than alternatives

The other members of the TufFoam team are: Tim Evans (11600), Steve Goods (8758), Jennifer Hallstrom (8528), Craig Henderson (1801), Mike Janes (8528), Pat Keifer (8778), Tim Shepodd (8778), Dawn Skala (8238), Roger Watson (8758), and Jim Wilhelm (8529).

TufFoam is a low-density, energy-absorbing foam originally conceived by Sandia materials scientists for NNSA as an encapsulant material to protect sensitive electronic and mechanical structures from harsh weapons environments. It is a water-blown, closed-cell, rigid polyurethane foam that features formulations as low as 2 pounds-per-cubic-foot density.

TufFoam garnered a lot of attention because of its potential as a material for surfboard blanks. It does not contain toluene diisocyanate (TDI), a chemical traditionally used in the production of surfboard blanks whose environmentally toxic properties have practically shut down the industry in the US. Currently most surfboard blanks are manufactured outside the US, but LeRoy believes there is still a niche market for "green" surfboards manufactured domestically.

Thermal conductivity is low, too

In the past year, the technical team has continued characterizing the mechanical properties and made comparisons to other competitive foams, discovering that its thermal conductivity is very low. The team has also added fire retardant to the formulation. Several of the potential commercial applications either require or would benefit from the material being fire retardant.

Whether it is eventually used on the beach, in a car, on a plane, or elsewhere, the outlook for TufFoam is good.

"We continue to get weekly inquiries about TufFoam and recently opened negotiations with a leading manufacturer of building materials," says LeRoy.