Necessity was the mother of invention for a recently licensed suite of microfluidic fittings, manifolds, and interconnects that allows researchers and engineers to configure their own analytical devices, as well as to potentially form integrated systems for myriad applications.

“It’s the only time at Sandia I’ve seen anything propagate like this,” said inventor Ron Renzi (8125). “It’s amazing how well-received these technologies were.” Among the team members responsible for the development were Distinguished Technologist Tom Raber (8125) and business development specialist Jim Wilhelm (8529), who handled the licensing agreement.

The suite was originally developed during the initial stages of the Grand Challenge µChemLab Laboratory Directed Research and Development (LDRD) program, Ron says, when he could not find commercially available components that enabled easily formed fluidic seals in small spaces. µChemLab was designed to enhance traditional wet-bench chemical analysis of such things as trace explosives and biotoxins by rapidly and portably separating samples on-chip under an applied voltage.

Through the help of Jim and Senior Manager Art Pontau of Materials and Energy Sciences Section 8750, the fittings were licensed late last year to LabSmith, a Livermore-based hardware company formed by former Sandians Eric Cummings and Kirsten Pace.

Working on the initial µChemLab project eight years ago with designer Mark Claudnic (8948), the team developed the first component, called CapTite — a one-piece ferruled fitting with thread connections for sealing to thin, flexible capillaries. This solved the problem of getting fluids to microchannels on chips in a way that prevents troublesome leaks or bubbles.

The next year, manifolds and interfaces that provide consistent fluid connections with simple and accurate alignment were developed. Ron said the suite of tools has become much used in the last three or four years, adding, “It really is miniature plumbing made simple.”

The initial grant has spawned work in many Sandia programs, including those sponsored by the Department of Homeland Security (DHS), DoD, National Institutes of Health (NIH), and numerous LDRD programs.

Microthruster development

A specific application example includes LDRD-funded microthruster development, in which designs are being explored for using propellants in nanosatellites for uses such as communications, surveillance, or networking. The fittings allow different configurations to be tested so that mixing an oxidizer to increase thrust can be investigated. The liquid propellants are moved using electrokinetic pumping, in which an electric field causes bulk electroosmotic flow of a liquid in a packed bed within the capillary. The flow reaches the closed end of a capillary and drives a reverse, pressure-driven flow that can be tailored to the application by altering the size of particles in the packed bed.

Several patents have been issued or applied for with the assistance of Scott Ferko (8125), a co-inventor of the patented one-piece ferrule. Patents awarded so far include those associated with compression manifolds, microvalves, and high-pressure fittings. The high-pressure fitting is capable of withstanding up to 40,000 psi and can be used in smaller versions of the standard benchtop analytical tool, high-pressure liquid chromatography systems requiring about 10,000 psi. If scaled down, the technique can potentially be made quicker and more selective, sensitive, and convenient.

The microvalves include a multiport selector valve that has been continuously improved over the last two years, and is now frequently and reliably employed in microflow and nanoflow systems.

“The valves have been tested for more than 250,000 cycles, demonstrating a robustness that enables creation of reliable autonomous systems in the field,” says Microfluidics Dept. 8324 Manager Yolanda Fintschenko.

The fittings are also being used to enable selective concentrators that exploit differences in conductivity between particles and the suspending liquid in the presence of a nonuniform electric field.

Sandia researchers improved upon using this well-known force phenomenon (termed dielectrophoresis) for these devices by placing insulating obstacles within microchannels, and the associated electrodes outside in reservoirs. The insulating posts, arrayed in the middle of the microchannel, constrict the electric field and create a field gradient that gives rise to the dielectrophoretic particle separation. This approach is much easier to fabricate (using injection-molded polymers) than the previous glass-based approach. They say their technology, known as iDEP (for insulator-based dielectrophoresis), could revolutionize biological sample preparation. The iDEP technology is currently the focus of a cooperative research and development agreement with Lockheed Martin.

In New Mexico, these tools are enabling a discovery platform for mechanical testing, optical interrogation, electronic manipulation, and measurement at the Center for Integrated Nanotechnologies. Generally, there are applications in proteomics, genomics, chromatography, a variety of microassemblies, and in medical, defense, and similar fields.

One medical diagnostic application is a small portable device that within minutes should be able to screen saliva for markers of periodontal disease, and blood for early indicators of heart disease. Funded by the NIH, the R&D effort includes collaborators at the University of Michigan School of Dentistry and its School of Engineering, as well as the Cornell University School of Applied and Engineering Physics.

Terry Michalske, director of Biological & Energy Sciences Center 8300, has called the research team’s results “truly world-class,” saying, “They have succeeded in combining cutting-edge science and engineering to achieve something that has the potential to revolutionize medical diagnostics.”

“The initial investment blossomed into a real success story, and a fundamental strong element of that was the engineering,” Ron says. “It’s gone a long way. . . . We have great science here, and we also have great engineering to enable the science.”

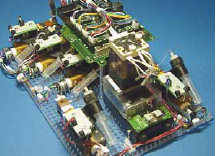

More than 20 second-generation µChemLab boxes relying on the aforementioned technologies are currently used in Sandia programs. The components are modular and employ a common breadboard and control architecture.

“Researchers can grab the components, draw a flow schematic, integrate and assemble the parts in hours instead of days, weeks, or months,” Ron says. “We want to take the chemist away from the problem and not be doing wet chemistry out in the field.”

Ron is also lead engineer on a team incorporating the fittings and other enabling technologies into the BioBriefcase project, an environmental monitoring collaboration with Lawrence Livermore National Laboratory (LLNL). The DHS-sponsored project calls for a compact broad-spectrum bioagent detector that autonomously collects, prepares, and analyzes samples using three techniques (DNA amplification using polymerase chain reaction to identify pathogens, immunoassays to detect pathogens and toxins, and fluorescence tagging to identify protein toxins) in a portable unit complete with a system to archive samples for further analysis.

Another DHS-funded project using this suite of microfluidic tools is the Enhanced Bioaerosol Detection project. Besides Sandia, it includes LLNL, Oak Ridge, Pacific Northwest, and Los Alamos national laboratories, as well as Yale University and the Army Research Laboratory. The prototype, slated for testing in August, is a selective aerosol collector and fluorescence spectrometer under investigation for potential use as a low-false-alarm-rate early warning bioaerosol sensor.

“The technologies have propagated through different programs,” Ron says, “not all of which they were invented for.” This is likely to continue as the field of microfluidics and its applications evolve.