5.2. Material Models

This section contains descriptions of the general fully supported materials available in Sierra/SM. Additional models relevant to shock problems are described in the separate Sierra/SM ITAR User’s Guide: Addendum for Shock Capabilities. Also, additional experimental, in-development, and specialty models may be found in the Sierra/SM Capabilities in Development manual.

5.2.1. Elastic Model

BEGIN PARAMETERS FOR MODEL ELASTIC

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

END [PARAMETERS FOR MODEL ELASTIC]

The elastic model is a hypoelastic extension of isotropic, small-strain, linear elasticity [[1], [2], [3]]. The stress-strain response for an isotropic, elastic material is

where the Lamé constants, \(\lambda\) and \(\mu\), are given by

This model is extended to a finite-deformation, hypoelastic model by first making it a rate equation. Then the stress rate is replaced with an objective stress rate and the strain rate is replaced with the rate of deformation. This gives us

The stress rate is arbitrary, as long as it is objective. Two objective stress rates are commonly used: the Jaumann rate and the Green-McInnis rate. For problems with fixed principal axes of deformation, these two rates give the same answers. For problems where the principal axes of deformation rotate during the deformation, the two rates can give different answers. Generally speaking there is no reason to pick one objective rate over another. Sierra/SM uses the Green-McInnis rate.

The fourth-order elastic moduli are used in many constitutive models. There are many equivalent representations for the elastic moduli. In index notation we present the following three representations

where \(K\) is the elastic bulk modulus and is given by

See Section 5.1.5 for more information on elastic constants input.

There are no output variables available for the elastic model. For information about the elastic model, consult [[4]].

5.2.2. Thermoelastic Model

BEGIN PARAMETERS FOR MODEL THERMOELASTIC

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Thermoelastic functions

#

YOUNGS MODULUS FUNCTION = <string> ym_function_name

POISSONS RATIO FUNCTION = <string> pr_function_name

END [PARAMETERS FOR MODEL THERMOELASTIC]

The thermoelastic material model is used to describe a temperature-dependent linear elastic material. This is a hypoelastic model generally valid for small strains.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The

YOUNGS MODULUS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope. The function defines a scale factor on Young’s modulus as a function of temperature.The

POISSONS RATIO FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope. The function defines a scale factor on Poisson’s ratio as a function of temperature.

For information about the thermoelastic model, consult [[4]]. Several plasticity models share the same underlying implementation. Output state variables available for this model are listed in Table 5.9. Note, depending on options used (temperature dependence of properties, failure, etc.) some of these state variables may not be computed.

5.2.3. Neo-Hookean Model

BEGIN PARAMETERS FOR MODEL NEO_HOOKEAN

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

END [PARAMETERS FOR MODEL NEO_HOOKEAN]

The neo-Hookean model is a hyperelastic generalization of isotropic, small-strain linear elasticity. The stress-strain response for the neo-Hookean model may be determined from a free energy function - in this case the strain energy density, \(W\). The form of the strain energy density ([[5]]) is

where \(K\) and \(\mu\) are the bulk and shear moduli, respectively. The deformation measure is given by \(C_{ij}\), the components of the right Cauchy-Green tensor, where \(C_{ij} = F_{ki}F_{kj}\). The determinant of the deformation gradient is given by \(J\) and is a measure of the volumetric part of the deformation. \(\bar{C}_{ij}\) provides the isochoric part of the deformation and is given by

The second Piola-Kirchoff stress, with components \(S_{ij}\), may be determined by taking a derivative of the strain energy density and the Cauchy stress may be found by mapping from the second Piola-Kirchoff stress. The components of the Cauchy stress are

where \(B_{ij} = F_{ik}F_{jk}\), are the components of the left Cauchy-Green tensor and \(\delta_{ij}\) is the Kronecker delta.

Linearizing (5.3) we recover small strain linear elasticity

The neo-Hookean model is used for the recoverable (elastic) part for a number of inelastic, finite deformation constitutive models.

There are no output variables available for the neo-Hookean model.

5.2.4. Elastic Fracture Model

BEGIN PARAMETERS FOR MODEL ELASTIC_FRACTURE

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Fracture parameters

#

MAX STRESS = <real>

CRITICAL CRACK OPENING STRAIN = <real>

END [PARAMETERS FOR MODEL ELASTIC_FRACTURE]

The elastic fracture model is linear elastic model with a simple failure model using a maximum-principal-stress failure criterion. Post failure, the stress decays isotropically based on additional strain parallel to the maximum principal stress. The critical crack opening strain, \(\varepsilon_{ccos}\) is the value of the component of strain over which the stress is decayed to zero. This strain parameter can be adjusted so that failure is mesh independent.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The maximum principal stress at which failure occurs is defined with the

MAX STRESScommand line.The component of strain over which the stress decays to zero is defined with the

CRITICAL CRACK OPENING STRAINcommand line. This component of strain is aligned with the maximum-principal-stress direction at failure.

Output variables available for this model are listed in Table Table 5.1.

Name |

Variable Description |

|---|---|

|

Critical value of opening strain |

|

Crack opening direction - vector |

|

Crack opening direction - x component |

|

Crack opening direction - y component |

|

Crack opening direction - z component |

|

Value of maximum principal stress |

|

Von Mises stress at failure |

|

Stress tensor pressure at failure |

|

Maximum principal stress (UQ) |

|

Critical crack opening strain (UQ) |

5.2.5. Elastic-Plastic Model

BEGIN PARAMETERS FOR MODEL ELASTIC_PLASTIC

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Hardening Behavior

#

YIELD STRESS = <real>

BETA = <real> (1.0)

HARDENING MODULUS = <real>

END [PARAMETERS FOR MODEL ELASTIC_PLASTIC]

The elastic-plastic model is a hypoelastic, rate-independent linear hardening plasticity model. The rate form of the constitutive equation assumes an additive split of the rate of deformation into an elastic and plastic part

The stress rate only depends on the elastic strain rate in the problem

where \(\mathbb{C}_{ijkl}\) are the components of the fourth-order, isotropic elasticity tensor.

The key to the model is finding the plastic rate of deformation. For associated flow the plastic rate of deformation is in a direction normal to the yield surface. The yield surface is given by

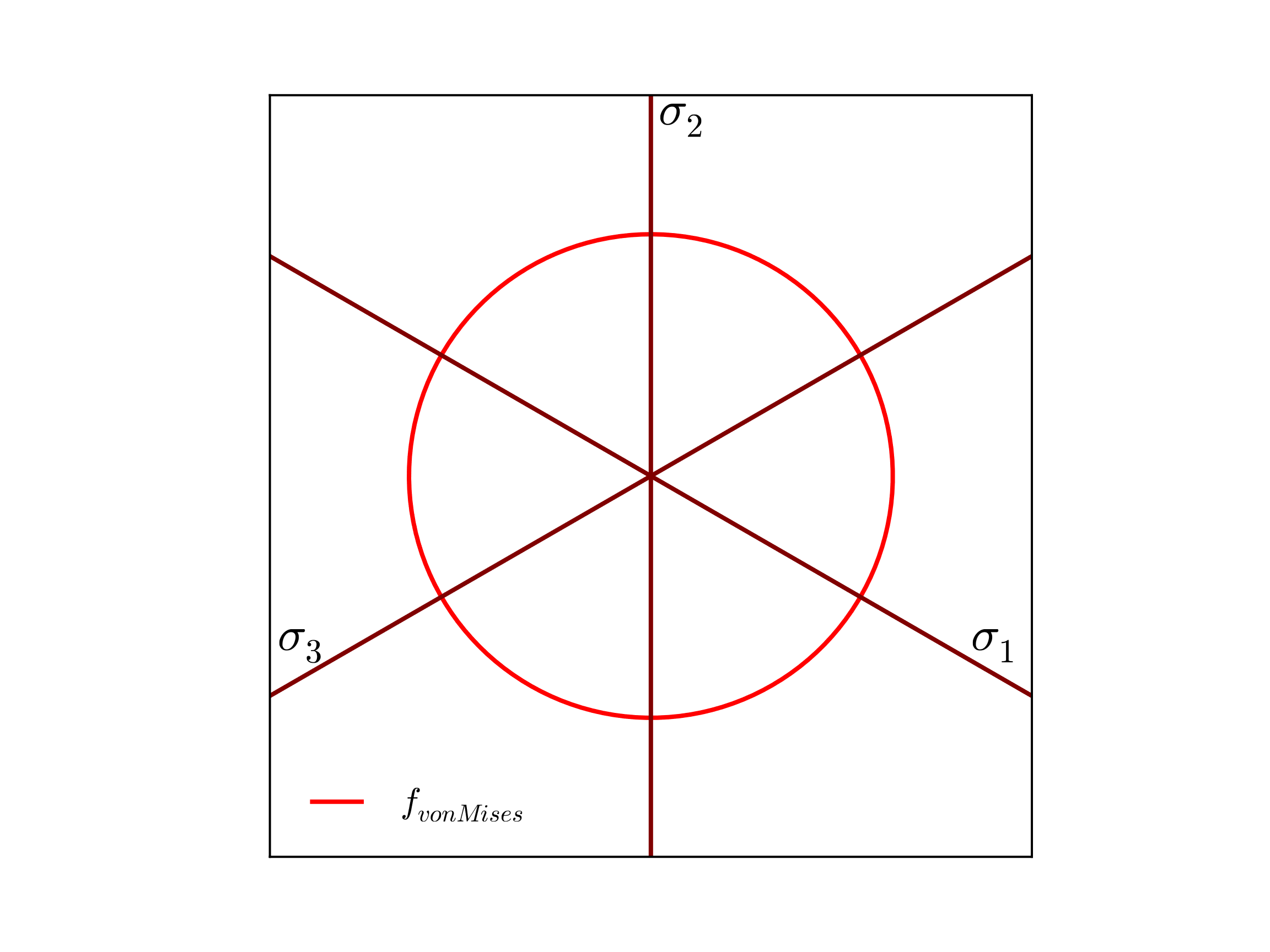

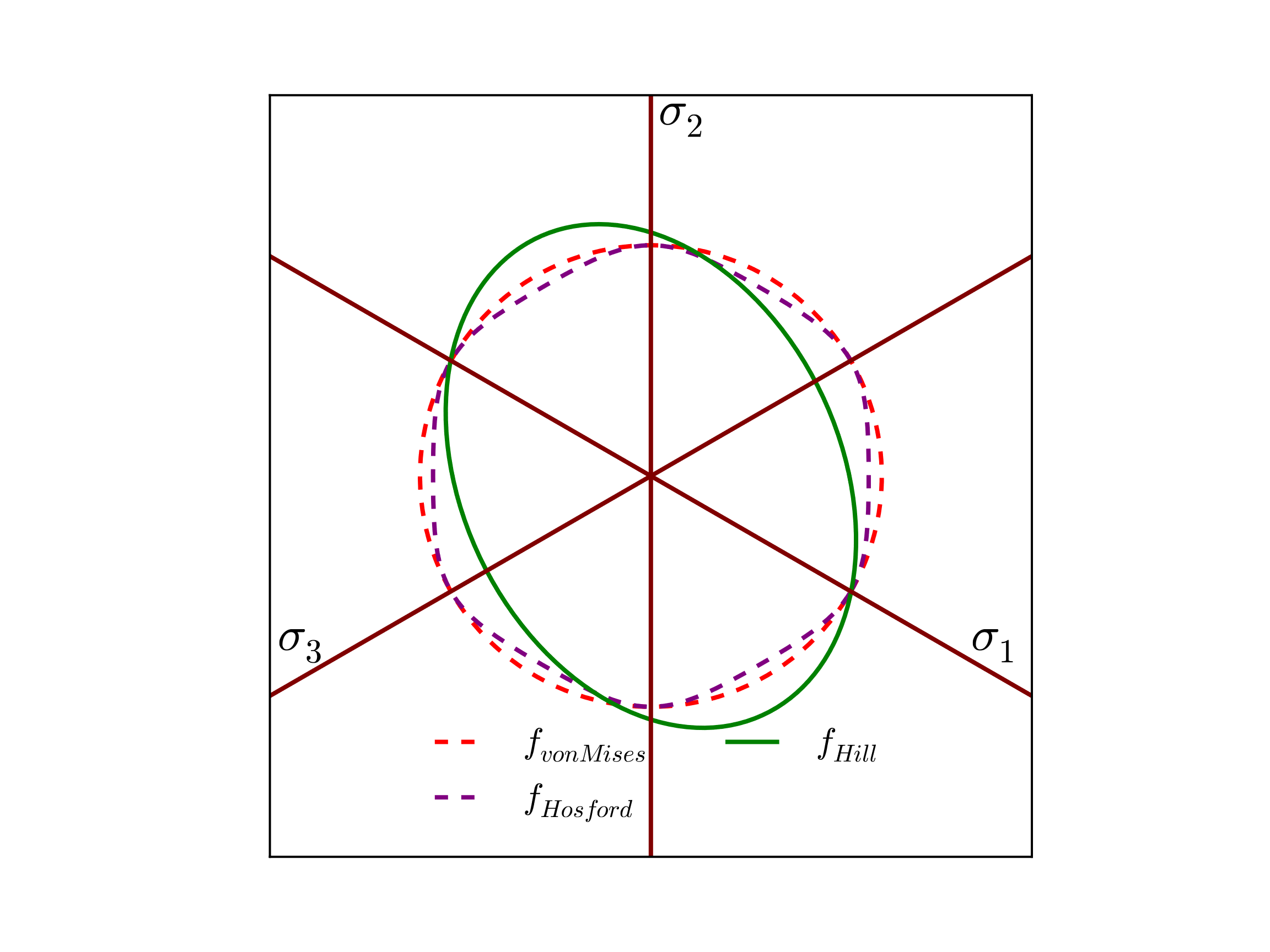

where \(\phi\) is the effective stress, \(\alpha_{ij}\) are the components of the back stress (used with kinematic hardening), and \(\bar{\sigma}\) is the hardening function which is a function of an internal state variable, the equivalent plastic strain \(\bar{\varepsilon}^{p}\). An example of such a yield surface (plotted in the deviatoric \(\pi\)-plane) is presented below in Fig. 5.4. The isotropy of the yield surface is clearly evident.

Fig. 5.4 Example von Mises yield surface (\(J_2\)) used by the elastic-plastic model presented in the deviatoric \(\pi\)-plane. In this case the surface is plotted for \(\alpha_{ij}=0\) and \(\bar{\varepsilon}^p=0\).

For the elastic plastic model a linear hardening law is assumed

where \(\sigma_{y}\) is the yield stress and \(H^{\prime}\) is the hardening modulus. If the stress state is such that \(f < 0\), the the behavior of the material is elastic; if the stress state is such that \(f = 0\) and \(\dot{f} < 0\), i.e. the strain rate brings the stress inside the yield surface, then the behavior of the material is elastic; if the stress state is such that \(f = 0\) and \(\dot{f} > 0\), i.e. the strain rate brings the stress outside the yield surface, then plastic deformation occurs.

We assume associated flow in this model, which gives the plastic rate of deformation

where \(\dot{\gamma}\) is the consistency parameter. For the elastic-plastic model the yield surface is assumed to be a von Mises yield surface with a back stress tensor to denote the center of the yield surface. The effective stress for a von Mises yield surface is

where \(s_{ij}\) are the components of the deviatoric stress tensor

and \(\alpha_{ij}\) are the components of the back stress tensor, another internal state variable.

The equivalent plastic strain is found through equating the rate of plastic work

Finally, the model allows for kinematic hardening through the back stress. The back stress is a symmetric, deviatoric rank two tensor that evolves in the following manner

The radius of the yield surface can be defined, \(R = \sqrt{\xi_{ij}\xi_{ij}}\). The evolution of the radius of the yield surface is given by

In (5.13) and (5.14) the parameter \(\beta \in [0,1]\) distributes the hardening between isotropic and kinematic hardening. If \(\beta = 1\) the hardening is isotropic, if \(\beta = 0\) the hardening is kinematic, and if \(\beta\) is between 0 and 1 the hardening is a combination of isotropic and kinematic. In the above command blocks:

See Section 5.1.5 for more information on elastic constants input. The elastic constants describe both the pre-yield behavior of the model and the slope of post yield unloading.

The yield stress, the stress at which yield first initiates, is defined with the

YIELD STRESScommand line.The hardening modulus, the slope of the post yield hardening curve, is defined with the

HARDENING MODULUScommand line.The beta parameter defines if hardening is isotropic or kinematic. See Section 5.1.6 for details on the beta parameter.

Output variables available for this model are listed in Table 5.2 and Table 5.3. For information about the elastic-plastic model, consult [[4]].

Name |

Description |

|---|---|

|

equivalent plastic strain, \(\bar{\varepsilon}^{p}\) |

|

radius of the yield surface, \(R\) |

|

back stress (symmetric tensor), \(\alpha_{ij}\) |

Name |

Description |

|---|---|

|

equivalent plastic strain, \(\bar{\varepsilon}^{p}\) |

|

equivalent plastic strain only accumulated when the material is in tension (trace of stress tensor is positive) |

|

radius of the yield surface, \(R\) |

|

back stress (symmetric tensor), \(\alpha_{ij}\) |

|

radial return iterations |

|

error in plane stress iterations |

|

plane stress iterations |

|

integrated thickness strain |

5.2.6. Elastic-Plastic Power-Law Hardening Model

BEGIN PARAMETERS FOR MODEL EP_POWER_HARD

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Hardening behavior

#

YIELD STRESS = <real>

HARDENING CONSTANT = <real>

HARDENING EXPONENT = <real>

LUDERS STRAIN = <real>

END [PARAMETERS FOR MODEL EP_POWER_HARD]

The elastic-plastic power law hardening model is a hypoelastic, rate-independent plasticity model with power law hardening [[6]]. The rate form of the constitutive equation assumes an additive split of the rate of deformation into an elastic and plastic part

The stress rate only depends on the elastic strain rate in the problem

where \(\mathbb{C}_{ijkl}\) are the components of the fourth-order, isotropic elasticity tensor.

The key to integrating the model is finding the plastic rate of deformation. For associated flow the plastic rate of deformation is in a direction normal to the yield surface. The yield surface is given by

where \(\phi\) is the equivalent stress and \(\bar{\sigma}\) is the hardening function which is a function of the equivalent plastic strain \(\bar{\varepsilon}^{p}\). For this model the hardening function uses a power law

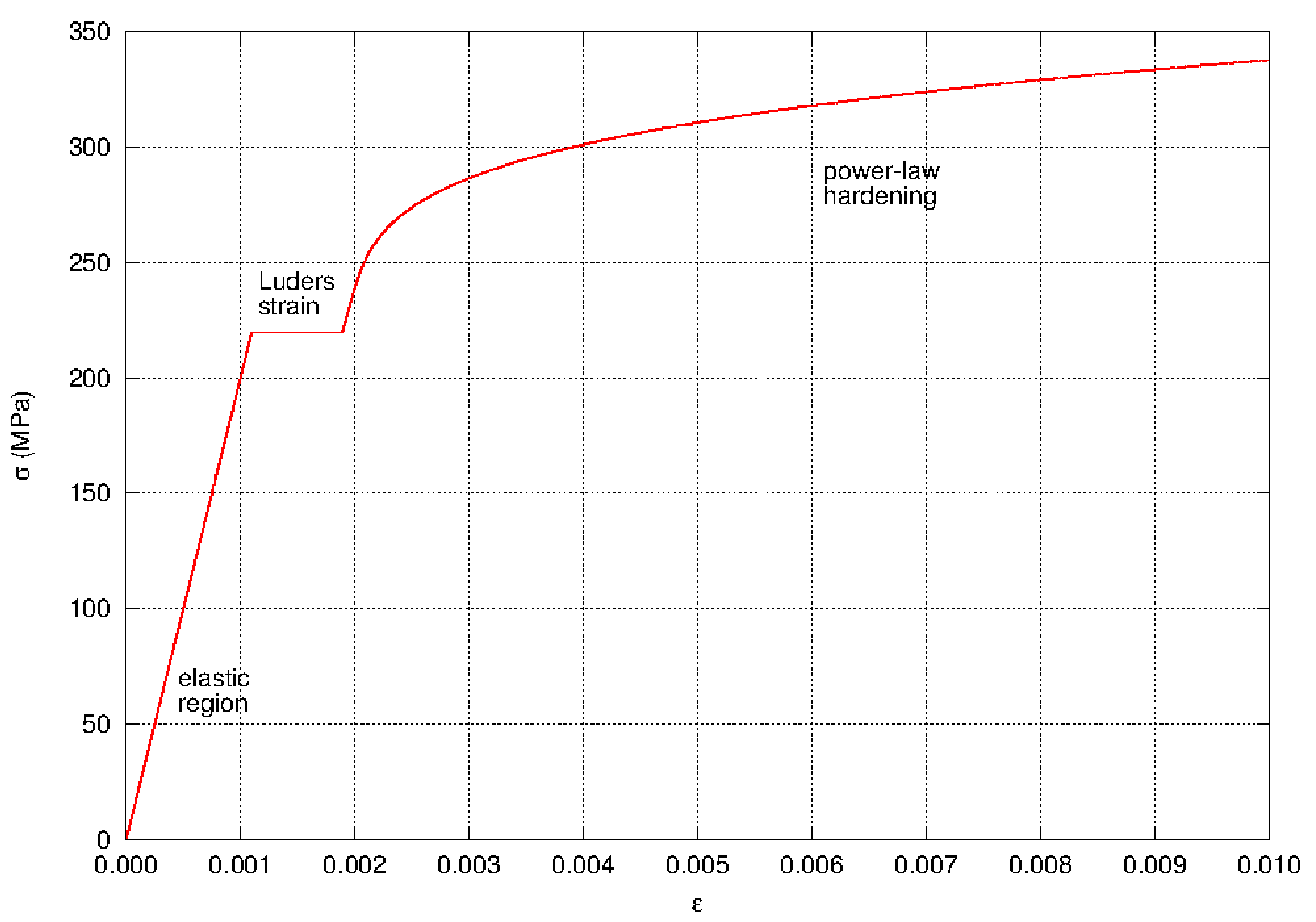

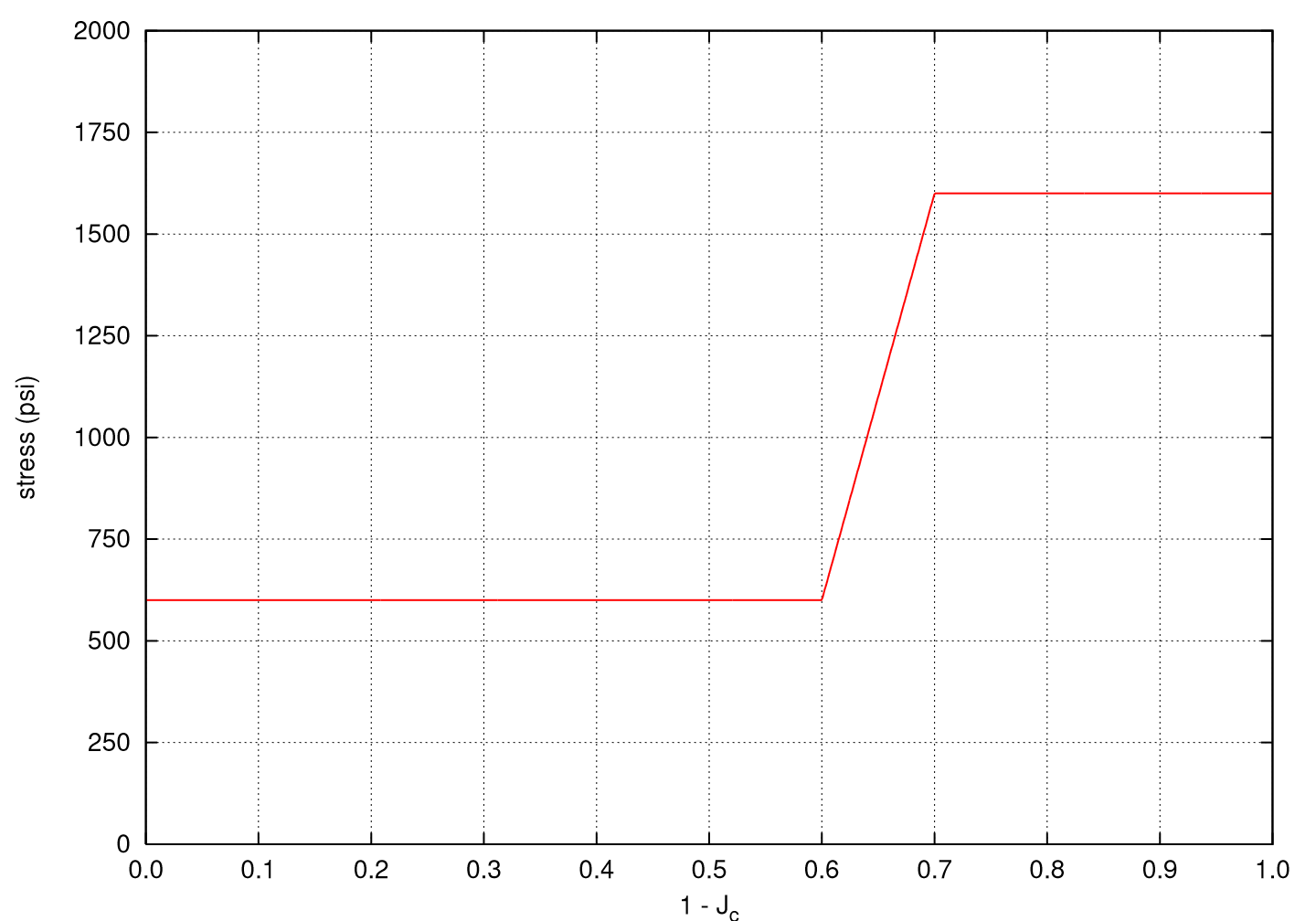

Fig. 5.5 Typical stress-strain response for the power-law hardening model.

which is shown in Fig. 5.5. The yield stress is \(\sigma_{y}\), the hardening constant is \(A\), the hardening exponent is \(n\), and the L"{u}ders strain is \(\varepsilon_{L}\). The bracket \(<\cdot>\) is the Macaulay bracket defined as

By assuming associated plastic flow, the plastic rate of deformation can be written as

For this model the yield surface is chosen to be a von Mises yield surface, so

where \(s_{ij}\) are the components of the deviatoric stress

Unlike the elastic-plastic model Section 5.2.5, the power-law hardening model does not allow for kinematic hardening, so there is no back stress.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The

YIELD STRESSis the stress at which the plastic power law yielding and hardening model takes effect. See Fig. 5.5.The

LUDERS STRAINdefines a regime of zero hardening modulus prior to onset of the power law hardening. A small Luder band is seen in the hardening behavior or many metals. See Fig. 5.5 for details.The

HARDENING CONSTANTcommand line andHARDENING EXPONENTcommand define the power law hardening curve. Past the Luder strain the hardened yield surface radius is given by theHARDENING CONSTANTtimes plastic strain to theHARDENING EXPONENTpower.

Output variables available for this model are listed in Table 5.4 and Table 5.5. For information about the elastic-plastic power-law hardening model, consult [[4]].

Name |

Description |

|---|---|

|

equivalent plastic strain, \(\bar{\varepsilon}^{p}\) |

|

equivalent plastic strain only accumulated when the material is in tension (trace of stress tensor is positive) |

|

radius of yield surface, \(R\) |

|

number of radial return iterations |

Name |

Description |

|---|---|

|

equivalent plastic strain, \(\bar{\varepsilon}^{p}\) |

|

equivalent plastic strain only accumulated when the material is in tension (trace of stress tensor is positive) |

|

radius of yield surface, \(R\) |

|

number of radial return iterations |

|

error in plane stress iterations |

|

plane stress iterations |

5.2.7. Ductile Fracture Model

BEGIN PARAMETERS FOR MODEL DUCTILE_FRACTURE

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Yield surface parameters

#

YIELD STRESS = <real>

HARDENING CONSTANT = <real>

HARDENING EXPONENT = <real>

LUDERS STRAIN = <real>

#

# Failure parameters

#

CRITICAL TEARING PARAMETER = <real>

CRITICAL CRACK OPENING STRAIN = <real>

END [PARAMETERS FOR MODEL DUCTILE_FRACTURE]

The ductile fracture model is identical to the elastic-plastic power-law hardening model with the addition of a failure criterion and an isotropic decay of the stress to zero during the failure process within the constitutive model. To accomplish this task, the tearing parameter, \(t_p\), proposed by Wellman [[7]] is introduced and the functional form as given as

where \(\sigma_{\max }\) is the maximum principal stress, and \(\sigma _{m}\) is the mean stress. It can also be noted that the tearing parameter evolves during the plastic deformation regime as indicated by integrating over the effective plastic strain, \(\bar{\varepsilon}^{p}\). The angle brackets denoting the Macaulay brackets, where

are used to ensure that the failure process occurs only with tensile stress states and prevent “damage healing”. The failure process then initiates at a critical tearing parameter, \(t_p^{\text{crit}}\), and the corresponding stress decay occurs over a strain interval corresponding to the critical crack opening strain, \(\varepsilon_{\text{ccos}}\). Importantly, the \(\varepsilon_{\text{ccos}}\) serves a dual role in that it may also be used to control the energy dissipated during failure. With respect to the latter point, careful selection of the critical crack opening strain may be used to ensure consistent energy is dissipated through different meshes. This decay process is isotropic and linear with the current damage value being equivalent to the ratio of crack opening strain in the direction of the maximum principal stress to the critical value.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The

YIELD STRESSis the stress at which the plastic power load yielding and hardening model takes effect. See Fig. 5.5.The

LUDERS STRAINdefines a regime of zero hardening modulus prior to onset of the power law hardening. A small Luder band is seen in the hardening behavior or many metals. See Fig. 5.5 for details.The

HARDENING CONSTANTcommand line andHARDENING EXPONENTcommand define the power law hardening curve. Past the Luder strain the hardened yield surface radius is given by theHARDENING CONSTANTtimes plastic strain to theHARDENING EXPONENTpower.CRITICAL TEARING PARAMETERdefines the \(t_{p}\) value at which fracture and subsequent decay of stress will occur.When the model undergoes additionally strain after reaching the critical tearing parameter the stress in the model will decay to zero. The amount strain over which the stress decays to zero is defined with the

CRITICAL CRACK OPENING STRAINcommand line. The relevant opening strain is the component of strain that is aligned with the maximum-principal-stress direction at initial failure.

Output variables available for this model are listed in Table 5.6. For information about the ductile fracture material model, consult [[7]].

Name |

Description |

|---|---|

|

equivalent plastic strain, \(\bar{\varepsilon}^{p}\) |

|

radius of yield surface, \(R\) |

|

back stress - tensor \(\alpha_{ij}\) |

|

Current value of the integrated tearing parameter |

|

Current value of the crack opening strain. Will be zero prior to reaching the maximum tearing parameter. |

|

Crack opening direction (maximum principal stress direction at failure) - vector |

|

XX component of current strain |

|

YY component of current strain |

|

ZZ component of current strain |

|

XY component of current strain |

|

YZ component of current strain |

|

ZX component of current strain |

|

Yield surface radius at failure |

|

Stress pressure norm at failure |

5.2.8. Multilinear Elastic-Plastic Hardening Model

BEGIN PARAMETERS FOR MODEL MULTILINEAR_EP

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Hardening behavior

#

YIELD STRESS = <real>

BETA = <real> (1.0)

HARDENING FUNCTION = <string> hardening_function_name

#

# Functions

#

YOUNGS MODULUS FUNCTION = <string> ym_function_name

POISSONS RATIO FUNCTION = <string> pr_function_name

YIELD STRESS FUNCTION = <string> yield_stress_function_name

END [PARAMETERS FOR MODEL MULTILINEAR_EP]

The multilinear elastic-plastic model is a generalization of the standard rate independent plasticity models already presented - the linear and power law hardening models. However, rather than having a specific functional form, the multilinear hardening model allows the user to input a piecewise linear function for the hardening curve. The rate form of the constitutive equation assumes an additive split of the rate of deformation into an elastic and plastic part such that

The stress rate only depends on the elastic strain rate so that,

where \(\mathbb{C}_{ijkl}\) are the components of the fourth-order, isotropic elasticity tensor.

The key to the model is finding the plastic rate of deformation. For associated flow, the plastic rate of deformation is in the direction normal to the yield surface. With a yield surface given by

then the plastic rate of deformation can be written as

For this model the yield surface is taken to be a von Mises yield surface, such that

where \(s_{ij}\) are the components of the deviatoric stress

For simplicity it is easier to write (5.18) in terms of the normal to the yield surface

The model also incorporates temperature dependence in that the elastic properties and the yield stress can be functions of temperature. This is not as general as having the yield curves depend on temperature. For that behavior the thermoelastic-plastic model can be used.

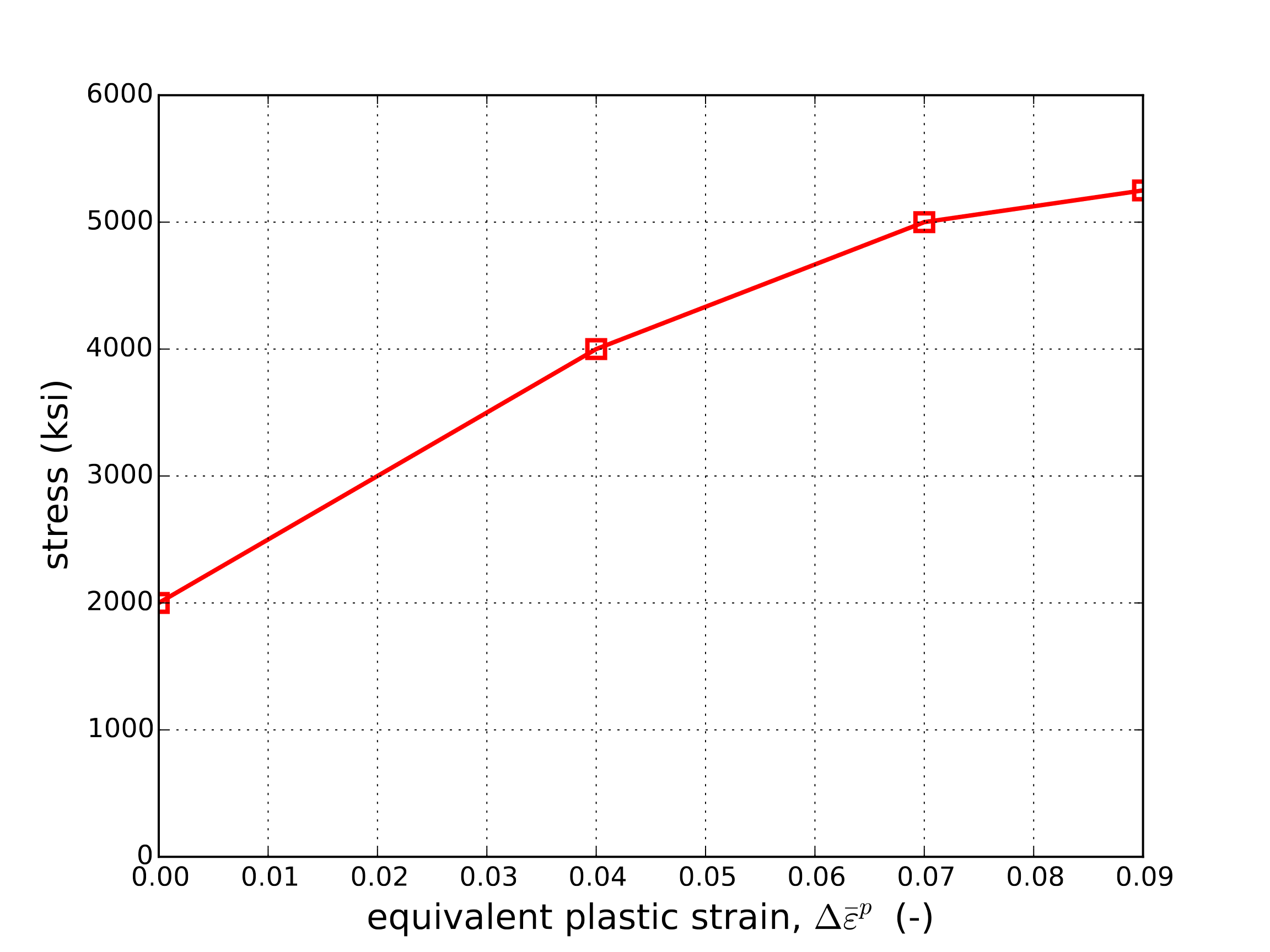

An example stress vs. plastic strain hardening curve is shown in Fig. 5.6. This curve was generated for a loading case of uniaxial strain. In this case, the effective stress is the same as the uniaxial. Therefore, for use with the multilinear elastic-plastic model this curve would simply have to be discretized and used as input.

Fig. 5.6 An example of a multilinear elastic-plastic stress-strain curve.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The beta parameter defines if hardening is isotropic or kinematic. See Section 5.1.6 for details on the beta parameter.

YIELD STRESSdefines the stress where plastic yielding first occurs.The

HARDENING FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope. The function describes the hardening behavior of the material as stress versus equivalent plastic strain. The x values of the function should be values of equivalent plastic strain while the y values of the function can be either the increment of stress over the yield stress or the actual stress at the corresponding equivalent plastic strain. Note the hardening function can have its first point defined at (0,0), or at (0,YIELD_STRESS). Either function definition behaves the same as only the slope of the hardening function between two strains is used by the model.The

YOUNGS MODULUS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Young’s modulus as a function of temperature.The

POISSONS RATIO FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Poisson’s ratio as a function of temperature.The

YIELD STRESS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on the yield stress as a function of temperature.

Output variables available for this model are listed in Table 5.7 and Table 5.8.

Name |

Description |

|---|---|

|

equivalent plastic strain |

|

equivalent plastic strain only accumulated when the material is in tension (trace of stress tensor is positive) |

|

radius of yield surface |

|

back stress (symmetric tensor) |

|

the current Young’s modulus as a function of temperature |

|

the current Poisson’s ratio as a function of temperature |

|

the current yield stress as a function of temperature |

|

radial return iterations |

|

inside (0) or on (1) the yield surface |

Name |

Description |

|---|---|

|

equivalent plastic strain |

|

equivalent plastic strain only accumulated when the material is in tension (trace of stress tensor is positive) |

|

radius of yield surface |

|

back stress (symmetric tensor) |

|

the current Young’s modulus as a function of temperature |

|

the current Poisson’s ratio as a function of temperature |

|

the current yield stress as a function of temperature |

|

radial return iterations |

|

error in plane stress iterations |

|

plane stress iterations |

5.2.9. Multilinear Elastic-Plastic Hardening Model with Failure

BEGIN PARAMETERS FOR MODEL ML_EP_FAIL

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Hardening behavior

#

YIELD STRESS = <real>

BETA = <real> (1.0)

HARDENING FUNCTION = <string> hardening_function_name

#

# Functions

#

YOUNGS MODULUS FUNCTION = <string> ym_function_name

POISSONS RATIO FUNCTION = <string> pr_function_name

YIELD STRESS FUNCTION = <string> yield_stress_function_name

#

# Failure parameters

#

CRITICAL TEARING PARAMETER = <real>

CRITICAL CRACK OPENING STRAIN = <real>

CRITICAL BIAXIALITY RATIO = <real> critical_ratio(0.0)

FAILURE EXPONENT = <real> (4.0)

END [PARAMETERS FOR MODEL ML_EP_FAIL]

Like the ductile fracture model, the multilinear elastic-plastic fail model is an extension of an existing plasticity model (multilinear elastic-plastic) to include a ductile failure criteria. Again, the tearing parameter criterion and failure propagation model of Wellman [[7]] is selected. Specifically, this approach uses a failure criterion (the tearing parameter, \(t_p\)) that is based on the history of the plastic strain and stress states. Most failure criteria for ductile failure involve some form of the stress triaxiality, or the ratio of the pressure and the effective (shear) stress. The tearing parameter, however, is slightly different in that it depends on the pressure and the maximum principal stress and is given as,

with \(\sigma_{\text{max}}\) and \(\sigma_{m}\) being the maximum principal and mean stresses, respectively. The exponent \(m\) is typically taken to be 4 while the \(\langle \cdot \rangle\) are Macaulay brackets defined as,

and introduced so that failure only occurs and propagates under tensile stress states. Failure then initiates when the tearing parameter, \(t_p\), reaches a critical value, \(t_p^{\text{crit}}\). After this point, the stress decays (to 0) in a linear fashion according to the ratio of the crack opening strain in the maximum principal stress direction to its critical value, \(\varepsilon_{\text{ccos}}\). Modification and control of this latter parameter is important as it may be used to ensure consistent energy is dissipated through different meshes.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The beta parameter defines if hardening is isotropic or kinematic. See Section 5.1.6 for details on the beta parameter.

YIELD STRESSdefines the stress for onset of yielding and plasticity.The

HARDENING FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope. The function describes the hardening behavior of the material as stress versus equivalent plastic strain. The x values of the function should be values of equivalent plastic strain while the y values of the function can be either the increment of stress over the yield stress or the actual stress at the corresponding equivalent plastic strain. Note the hardening function can have its first point defined at (0,0), or at (0,YIELD_STRESS). Either function definition behaves the same as only the slope of the hardening function between two strains is used by the model.The

YOUNGS MODULUS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Young’s modulus as a function of temperature.The

POISSONS RATIO FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Poisson’s ratio as a function of temperature.The

YIELD STRESS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on the yield stress as a function of temperature.CRITICAL TEARING PARAMETERdefines the \(t_{p}\) value at which fracture and subsequent decay of stress will occur.When the model undergoes additionally strain after reaching the critical tearing parameter the stress in the model will decay to zero. The amount strain over which the stress decays to zero is defined with the

CRITICAL CRACK OPENING STRAINcommand line. The relevant opening strain is the component of strain that is aligned with the maximum-principal-stress direction at initial failure.The

CRITICAL BIAXIALITY RATIOcommand line should only be used under highly specific conditions and with extreme caution. It is intended only for the special case where the stress state is nearly biaxial, resulting in nearly identical principal strains. In this case, the eigenvector computation can give unreliable results for the direction vectors for the principal strains. If the ratio of the difference between two principal strains divided by their magnitude is less that the value specified by theCRITICAL BIAXIALITY RATIOcommand, the direction of the vector defining the crack opening strain will be given equal weight in each of the principal directions associated with those strains. The default value for the critical ratio is 0.0, which means that the principal directions will be accepted directly from the eigenvector computation. This command should only be used as a last resort if the loading is nearly biaxial and the default value has been demonstrated to lead to elements with high strains that are not failing long after reaching the critical tearing parameter.The

FAILURE EXPONENTcommand line specifies the exponent on the tearing parameter, the \(m\) parameter in (5.19). This exponent defaults to 4.0.

Output variables available for this model are listed in Table 5.9 and Table 5.10.

Name |

Variable Description |

|---|---|

|

Equivalent plastic strain |

|

Radius of yield surface |

|

back stress - tensor |

|

back stress - xx component |

|

back stress - yy component |

|

back stress - zz component |

|

back stress - xy component |

|

back stress - yz component |

|

back stress - zx component |

|

Current Young’s modulus as a function of temperature |

|

Current Poisson’s ratio as a function of temperature |

|

Current Yield stress as a function of temperature |

|

equivalent plastic strain only accumulated when the material is in tension (trace of stress tensor is positive |

|

radial return iteration |

|

inside(0) or on(1) yield surface |

|

Current integrated value of the tearing parameter. Zero until yield is reached |

|

Current value of the crack opening strain. Zero until the critical tearing parameter is reached |

|

crack opening direction at failure - vector |

|

crack opening direction at failure - x component |

|

crack opening direction at failure - y component |

|

crack opening direction at failure - z component |

|

maximum radius at initial failure |

|

maximum stress pressure norm at initial failure |

|

|

|

Name |

Variable Description |

|---|---|

|

equivalent plastic strain |

|

radius of yield surface |

|

back stress - tensor |

|

back stress - xx component |

|

back stress - yy component |

|

back stress - zz component |

|

back stress - xy component |

|

back stress - yz component |

|

back stress - zx component |

|

Current Young’s modulus as a function of temperature |

|

Current Poisson’s ratio as a function of temperature |

|

Current Yield stress as a function of temperature |

|

radial return iterations |

|

Error in plane stress iterations |

|

Plane stress iterations |

|

Current integrated value of the tearing parameter. Zero until yield is reached |

|

Current value of the crack opening strain. Zero until the critical tearing parameter is reached |

|

crack opening direction at failure - vector |

|

crack opening direction at failure - x component |

|

crack opening direction at failure - y component |

|

crack opening direction at failure - z component |

|

maximum radius at initial failure |

|

equivalent plastic strain only accumulated when the material is in tension (trace of stress tensor is positive) |

5.2.10. Elastic-Plastic Hardening Model with Failure

BEGIN PARAMETERS FOR MODEL ELASTIC_PLASTIC_FAIL

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Isotropic/Kinematic hardening factor

#

BETA = <real> (1.0)

YIELD STRESS = <real>

HARDENING FUNCTION = <string>hardening_function_name

POISSONS RATIO FUNCTION = <string>pr_function_name

YIELD STRESS FUNCTION = <string>yield_stress_function_name

YOUNGS MODULUS FUNCTION = <string>ym_function_name

#

# Failure parameters

#

CRITICAL TEARING PARAMETER = <real>crit_tearing

CRITICAL CRACK OPENING STRAIN = <real>critical_strain

END [PARAMETERS FOR MODEL ELASTIC_PLASTIC_FAIL]

This model behaves identical to the ML_EP_FAIL (Section 5.2.9) material mode and only exists for legacy syntax compatibility purposes.

5.2.11. Thermoelastic-Plastic Model

BEGIN PARAMETERS FOR MODEL THERMOELASTIC_PLASTIC

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Isotropic/Kinematic hardening factor

#

BETA = <real>beta_parameter(1.0)

YIELD STRESS = <real>yield_stress

YOUNGS MODULUS FUNCTION = <string>ym_function_name

POISSONS RATIO FUNCTION = <string>pr_function_name

YIELD STRESS FUNCTION = <string>ys_function_name

TEMPERATURES = <real(s)>temperature_values

HARDENING FUNCTIONS = <string(s)>hardening_functions

END [PARAMETERS FOR MODEL THERMOELASTIC_PLASTIC]

The thermoelastic-plastic model is similar to the elastic-plastic model, but allows for temperature-dependent changes of the material properties. All elastic-plastic input parameters are still valid for the thermoelastic-plastic model, in addition to the temperature dependent functions.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The beta parameter defines if hardening is isotropic or kinematic. See Section 5.1.6 for details on the beta parameter.

The yield stress, the stress at which yield first initiates, is defined with the

YIELD STRESScommand line.The

YIELD STRESS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Yield Stress as a function of temperature.The

YOUNGS MODULUS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Young’s modulus as a function of temperature.The

POISSONS RATIO FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Poisson’s ratio as a function of temperature.The

TEMPERATUREScommand line specifies the temperatures that correspond to the hardening functions defined in theHARDENING FUNCTIONScommand line. The number of temperatures input here must match the number of hardening functions input.The

HARDENING FUNCTIONScommand line references the names of the functions defined in aFUNCTIONcommand line in the SIERRA scope that describes the hardening behavior for the material as stress versus equivalent plastic strain at the temperatures defined in theTEMPERATUREScommand line. The number of hardening functions input here must match the number of temperatures input. If the material temperature exactly matches one of the input temperatures the hardening of the material will exactly follow the hardening curve associated with that temperature. If the material temperature is bracketed by two hardening curves the actual hardening curve taken will be linearly interpolated between the bracketing curves. If the material temperature is either above the highest defined temperature function or below the lowest defined temperature function the closest hardening curve will be used for the material hardening.

Several plasticity models share the same underlying implementation. Output state variables available for this model are listed in Table Table 5.9. Note, depending on options used (temperature dependence of properties, failure, etc.) some of these state variables may not be computed.

5.2.12. Thermoelastic-Plastic Model with Failure

BEGIN PARAMETERS FOR MODEL THERMOELASTIC_PLASTIC_FAIL

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Isotropic/Kinematic hardening factor

#

BETA = <real>beta_parameter(1.0)

TEMPERATURES = <real(s)>temperature_values

YIELD STRESS = <real>yield_stress

YOUNGS MODULUS FUNCTION = <string>ym_function_name

POISSONS RATIO FUNCTION = <string>pr_function_name

YIELD STRESS FUNCTION = <string>ys_function_name

HARDENING FUNCTIONS = <string(s)>hardening_functions

CRITICAL CRACK OPENING STRAIN = <real>critical_strain

CRITICAL TEARING PARAMETER = <real>crit_tearing

CRITICAL CRACK OPENING STRAIN FUNCTION

= <string>crack_open_strain_function_name

CRITICAL TEARING PARAMETER FUNCTION

= <string>tearing_parameter_function_name

END [PARAMETERS FOR MODEL THERMOELASTIC_PLASTIC_FAIL]

The thermoelastic-plastic model with failure is similar to the ELASTIC_PLASTIC_FAIL material model, but allows for additional temperature-dependent changes of the material.

In the above command blocks:

See Section 5.1.5 for more information on elastic constants input.

The beta parameter defines if hardening is isotropic or kinematic. See Section 5.1.6 for details on the beta parameter.

YIELD STRESSdefines the stress for onset of yielding and plasticity.The

TEMPERATUREScommand line specifies the temperatures that correspond to the hardening functions defined in theHARDENING FUNCTIONScommand line. The number of temperatures input here must match the number of hardening functions input.The

HARDENING FUNCTIONScommand line references the names of the functions defined in aFUNCTIONcommand line in the SIERRA scope that describes the hardening behavior for the material as stress versus equivalent plastic strain at the temperatures defined in theTEMPERATUREScommand line. The number of hardening functions input here must match the number of temperatures input. If the material temperature exactly matches one of the input temperatures the hardening of the material will exactly follow the hardening curve associated with that temperature. If the material temperature is bracketed by two hardening curves the actual hardening curve taken will be linearly interpolated between the bracketing curves. If the material temperature is either above the highest defined temperature function or below the lowest defined temperature function the closest hardening curve will be used for the material hardening.The

POISSONS RATIO FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on Poisson’s ratio as a function of temperature.The

YIELD STRESS FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on the yield stress as a function of temperature.CRITICAL TEARING PARAMETERdefines the \(t_{p}\) value at which fracture and subsequent decay of stress will occur.When the model undergoes additionally strain after reaching the critical tearing parameter the stress in the model will decay to zero. The amount strain over which the stress decays to zero is defined with the

CRITICAL CRACK OPENING STRAINcommand line. The relevant opening strain is the component of strain that is aligned with the maximum-principal-stress direction at initial failure.The

CRITICAL CRACK OPENING STRAIN FUNCTION `` command line references the name of a function defined in a ``FUNCTIONcommand line in the SIERRA scope that describes a scale factor on the crack opening strain as a function of temperature.The

CRITICAL TEARING PARAMETER FUNCTIONcommand line references the name of a function defined in aFUNCTIONcommand line in the SIERRA scope that describes a scale factor on the tearing parameter as a function of temperature.

Several plasticity models share the same underlying implementation. Output state variables available for this model are listed in Table Table 5.9. Note, depending on options used (temperature dependence of properties, failure, etc.) some of these state variables may not be computed.

5.2.13. J2 Plasticity Model

BEGIN PARAMETERS FOR MODEL J2_PLASTICITY

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Yield surface parameters

#

YIELD STRESS = <real>

BETA = <real> (1.0)

#

# Hardening model

#

HARDENING MODEL = LINEAR | POWER_LAW | VOCE | USER_DEFINED |

FLOW_STRESS | DECOUPLED_FLOW_STRESS | JOHNSON_COOK |

POWER_LAW_BREAKDOWN

#

# Linear hardening

#

HARDENING MODULUS = <real>

#

# Power-law hardening

#

HARDENING CONSTANT = <real>

HARDENING EXPONENT = <real> (0.5)

LUDERS STRAIN = <real> (0.0)

#

# Voce hardening

#

HARDENING MODULUS = <real>

EXPONENTIAL COEFFICIENT = <real>

#

# Johnson-Cook hardening

#

HARDENING FUNCTION = <string>hardening_function_name

RATE CONSTANT = <real>

REFERENCE RATE = <real>

#

# Power law breakdown hardening

#

HARDENING FUNCTION = <string>hardening_function_name

RATE COEFFICIENT = <real>

RATE EXPONENT = <real>

# User defined hardening

#

HARDENING FUNCTION = <string>hardening_function_name

#

#

# Following Commands Pertain to Flow_Stress Hardening Model

#

# - Isotropic Hardening model

#

ISOTROPIC HARDENING MODEL = LINEAR | POWER_LAW | VOCE |

USER_DEFINED

#

# Specifications for Linear, Power-law, and Voce same as above

#

# User defined hardening

#

ISOTROPIC HARDENING FUNCTION = <string>iso_hardening_fun_name

#

# - Rate dependence

#

RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Specifications for Johnson-Cook, Power-law-breakdown

# same as before EXCEPT no need to specify a

# hardening function

#

# User defined rate multiplier

#

RATE MULTIPLIER FUNCTION = <string> rate_mult_function_name

#

# - Temperature dependence

#

TEMPERATURE MULTIPLIER = JOHNSON_COOK | USER_DEFINED |

TEMPERATURE_INDEPENDENT (TEMPERATURE_INDEPENDENT)

#

# Johnson-Cook temperature dependence

#

MELTING TEMPERATURE = <real>

REFERENCE TEMPERATURE = <real>

TEMPERATURE EXPONENT = <real>

#

# User-defined temperature dependence

TEMPERATURE MULTIPLIER FUNCTION = <string>temp_mult_function_name

#

# Following Commands Pertain to Decoupled_Flow_Stress Hardening Model

#

# - Isotropic Hardening model

#

ISOTROPIC HARDENING MODEL = LINEAR | POWER_LAW | VOCE | USER_DEFINED

#

# Specifications for Linear, Power-law, and Voce same as above

#

# User defined hardening

#

ISOTROPIC HARDENING FUNCTION = <string>isotropic_hardening_function_name

#

# - Rate dependence

#

YIELD RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Specifications for Johnson-Cook, Power-law-breakdown same as before

# EXCEPT no need to specify a hardening function

# AND should be preceded by YIELD

#

# As an example for Johnson-Cook yield rate dependence,

#

YIELD RATE CONSTANT = <real>

YIELD REFERENCE RATE = <real>

#

# User defined rate multiplier

#

YIELD RATE MULTIPLIER FUNCTION = <string>yield_rate_mult_function_name

#

HARDENING_RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Syntax same as for yield parameters but with a HARDENING prefix

#

# - Temperature dependence

#

YIELD TEMPERATURE MULTIPLIER = JOHNSON_COOK | USER_DEFINED |

TEMPERATURE_INDEPENDENT (TEMPERATURE_INDEPENDENT)

#

# Johnson-Cook temperature dependence

#

YIELD MELTING TEMPERATURE = <real>

YIELD REFERENCE TEMPERATURE = <real>

YIELD TEMPERATURE EXPONENT = <real>

#

# User-defined temperature dependence

YIELD TEMPERATURE MULTIPLIER FUNCTION = <string>yield_temp_mult_fun_name

#

HARDENING TEMPERATURE MULTIPLIER = JOHNSON_COOK | USER_DEFINED |

TEMPERATURE_INDEPENDENT (TEMPERATURE_INDEPENDENT)

#

# Syntax for hardening constants same as for yield but

# with HARDENING prefix

#

# Optional Failure Definitions

# Following only need to be defined if intend to use failure model

#

FAILURE MODEL = TEARING_PARAMETER | JOHNSON_COOK_FAILURE | WILKINS

| MODULAR_FAILURE | MODULAR_BCJ_FAILURE

CRITICAL FAILURE PARAMETER = <real>

#

# TEARING_PARAMETER Failure model definitions

#

TEARING PARAMETER EXPONENT = <real>

#

# JOHNSON_COOK_FAILURE Failure model definitions

#

JOHNSON COOK D1 = <real>

JOHNSON COOK D2 = <real>

JOHNSON COOK D3 = <real>

JOHNSON COOK D4 = <real>

JOHNSON COOK D5 = <real>

#

#Following Johnson-Cook parameters can only be defined once. As such, only

# needed if not previously defined via Johnson-Cook multipliers

# w/ flow-stress hardening. Does need to be defined

# w/ Decoupled Flow Stress

#

REFERENCE RATE = <real>

REFERENCE TEMPERATURE = <real>

MELTING TEMPERATURE = <real>

#

# WILKINS Failure model definitions

#

WILKINS ALPHA = <real>

WILKINS BETA = <real>

WILKINS PRESSURE = <real>

#

# MODULAR_FAILURE Failure model definitions

#

PRESSURE MULTIPLIER = PRESSURE_INDEPENDENT | WILKINS

| USER_DEFINED (PRESSURE_INDEPENDENT)

LODE ANGLE MULTIPLIER = LODE_ANGLE_INDEPENDENT |

WILKINS (LODE_ANGLE_INDEPENDENT)

TRIAXIALITY MULTIPLIER = TRIAXIALITY_INDEPENDENT | JOHNSON_COOK

| USER_DEFINED (TRIAXIALITY_INDEPENDENT)

RATE FAIL MULTIPLIER = RATE_INDEPENDENT | JOHNSON_COOK

| USER_DEFINED (RATE_INDEPENDENT)

TEMPERATURE FAIL MULTIPLIER = TEMPERATURE_INDEPENDENT | JOHNSON_COOK

| USER_DEFINED (TEMPERATURE_INDEPENDENT)

#

# Individual multiplier definitions

#

PRESSURE MULTIPLIER = WILKINS

WILKINS ALPHA = <real>

WILKINS PRESSURE = <real>

#

PRESSURE MULTIPLIER = USER_DEFINED

PRESSURE MULTIPLIER FUNCTION = <string> pressure_multiplier_fun_name

#

LODE ANGLE MULTIPLIER = WILKINS

WILKINS BETA = <real>

#

TRIAXIALITY MULTIPLIER = JOHNSON_COOK

JOHNSON COOK D1 = <real>

JOHNSON COOK D2 = <real>

JOHNSON COOK D3 = <real>

#

TRIAXIALITY MULTIPLIER = USER_DEFINED

TRIAXIALITY MULTIPLIER FUNCTION = <string> triaxiality_multiplier_fun_name

#

RATE FAIL MULTIPLIER = JOHNSON_COOK

JOHNSON COOK D4 = <real>

# REFERENCE RATE should only be added if not previously defined

REFERENCE RATE = <real>

#

RATE FAIL MULTIPLIER = USER_DEFINED

RATE FAIL MULTIPLIER FUNCTION = <string> rate_fail_multiplier_fun_name

#

TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK

JOHNSON COOK D5 = <real>

# JC Temperatures should only be defined if not previously given

REFERENCE TEMPERATURE = <real>

MELTING TEMPERATURE = <real>

#

TEMPERATURE FAIL MULTIPLIER = USER_DEFINED

TEMPERATURE FAIL MULTIPLIER FUNCTION = <string> temp_multiplier_fun_name

#

# MODULAR_BCJ_FAILURE Failure model definitions

#

INITIAL DAMAGE = <real>

INITIAL VOID SIZE = <real>

DAMAGE BETA = <real> (0.5)

GROWTH MODEL = COCKS_ASHBY | NO_GROWTH (NO_GROWTH)

NUCLEATION MODEL = HORSTEMEYER_GOKHALE | CHU_NEEDLEMAN_STRAIN

| NO_NUCLEATION (NO_NUCLEATION)

#

GROWTH RATE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| RATE_INDEPENDENT

(RATE_INDEPENDENT)

GROWTH TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| TEMPERATURE_INDEPENDENT

(TEMPERATURE_INDEPENDENT)

#

NUCLEATION RATE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| RATE_INDEPENDENT

(RATE_INDEPENDENT)

NUCLEATION TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| TEMPERATURE_INDEPENDENT

(TEMPERATURE_INDEPENDENT)

#

# Definitions for individual growth and nucleation models

#

GROWTH MODEL = COCKS_ASHBY

DAMAGE EXPONENT = <real> (0.5)

#

NUCLEATION MODEL = HORSTEMEYER_GOKHALE

NUCLEATION PARAMETER1 = <real> (0.0)

NUCLEATION PARAMETER2 = <real> (0.0)

NUCLEATION PARAMETER3 = <real> (0.0)

#

NUCLEATION MODEL = CHU_NEEDLEMAN_STRAIN

NUCLEATION AMPLITUDE = <real>

MEAN NUCLEATION STRAIN = <real>

NUCLEATION STRAIN STD DEV = <real>

#

# Definitions for rate and temperature fail multiplier

# Note: only showing definitions for growth.

# Nucleation terms are the same just with NUCLEATION instead

# of GROWTH

#

GROWTH RATE FAIL MULTIPLIER = JOHNSON_COOK

GROWTH JOHNSON COOK D4 = <real>

GROWTH REFERENCE RATE = <real>

#

GROWTH RATE FAIL MULTIPLIER = USER_DEFINED

GROWTH RATE FAIL MULTIPLIER FUNCTION = <string> growth_rate_fail_mult_func

#

GROWTH TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK

GROWTH JOHNSON COOK D5 = <real>

GROWTH REFERENCE TEMPERATURE = <real>

GROWTH MELTING TEMPERATURE = <real>

#

GROWTH TEMPERATURE FAIL MULTIPLIER = USER_DEFINED

GROWTH TEMPERATURE FAIL MULTIPLIER FUNCTION = <string> temp_fail_mult_func

#

#

# Optional Adiabatic Heating/Thermal Softening Definitions

# Following only need to be defined if intend to use failure model

#

THERMAL SOFTENING MODEL = ADIABATIC | COUPLED

#

SPECIFIC HEAT = <real> # not needed for COUPLED

BETA_TQ = <real>

END [PARAMETERS FOR MODEL J2_PLASTICITY]

The \(J_2\) plasticity model is a generic implementation of a von Mises yield surface with kinematic and isotropic hardening features. Unlike other models (e.g. Elastic-Plastic, Elastic-Plastic Power Law) more flexible, general hardening forms are implemented enabling different isotropic hardening descriptions and some rate and/or temperature dependence.

As is common to other plasticity models in LAMÉ, the \(J_2\) plasticity model uses a hypoelastic formulation. As such, the total rate of deformation is additively decomposed into an elastic and plastic part such that

The objective stress rate, depending only on the elastic deformation, may then be written as,

where \(\mathbb{C}_{ijkl}\) is the fourth-order elastic, isotropic stiffness tensor.

The yield surface for the \(J_2\) plasticity model, \(f\), may be written,

in which \(\alpha_{ij},\bar{\varepsilon}^p,\dot{\bar{\varepsilon}}^p,\) and \(\theta\) are the kinematic backstress, equivalent plastic strain, equivalent plastic strain rate, and absolute temperature, respectively, while \(\phi\) and \(\bar{\sigma}\) are the effective stress and a generic form of the flow stress. Broadly speaking, the effective stress describes the shape of the yield surface and kinematic effects while the flow stress gives the size of the current yield surface. It should also be noted that in writing the yield surface in this way, the dependence on the state variables is split between the effective stress and flow stress functions.

For \(J_2\) plasticity, the effective stress is given as,

with \(s_{ij}\) being the deviatoric stress defined as \(s_{ij}=\sigma_{ij}-(1/3)\sigma_{kk}\delta_{ij}\). For the flow stress, a general representation of the form,

is allowed. In this fashion, the effects of rate (\(\hat{\sigma}_{\text{y,h}}\)) and temperature (\(\breve{\sigma}_{\text{y,h}}\)) dependence on yield (\(\sigma_y\)) and isotropic hardening (\(K\left(\bar{\varepsilon}^p\right)\)) are decomposed. Separate temperature and rate dependencies may be be specified for yield (subscript y) and hardening (h). This assumption is an extension of the multiplicative decomposition of the Johnson-Cook model [[8], [9]]. It should be noted that not all effects need to be included and the default parameterization of the hardening classes is such that the response is rate and temperature independent. The following section on plastic hardening will go into more detail on possible choices for functional representations.

An associated flow rule is utilized such that the plastic rate of deformation is normal to the yield surface and is given by,

where \(\dot{\gamma}\) is the consistency multiplier enforcing \(f=0\) during plastic deformation. Given the form of \(f\), it can also be shown that \(\dot{\gamma}=\dot{\bar{\varepsilon}}^p\).

Additional discussion on options for failure models and adiabatic heating may be found in [[10], [11]] and [[12]], respectively.

In the command blocks that define the \(J_2\) plasticity model:

The reference nominal yield stress, \(\bar{\sigma}\), is defined with the

YIELD STRESScommand line.The beta parameter defines if hardening is isotropic.

The type of hardening law is defined with the

HARDENING MODELcommand line, other hardening commands then define the specific shape of that hardening curve.The hardening modulus for a linear hardening model is defined with the

HARDENING MODULUScommand line.The hardening constant for a power law hardening model is defined with the

HARDENING CONSTANTcommand line.The hardening exponent for a power law hardening model is defined with the

HARDENING EXPONENTcommand line.The Luders strain for a power law hardening model is defined with the

LUDERS STRAINcommand line.The hardening function for a user defined hardening model is defined with the

HARDENING FUNCTIONcommand line.The shape of the spline for the spline based hardening is defined by the

CUBIC SPLINE TYPE,CARDINAL PARAMETER,KNOT EQPS, andKNOT STRESScommand lines.The isotropic hardening model for the flow stress hardening model is defined with the

ISOTROPIC HARDENING MODELcommand line.The function name of a user-defined isotropic hardening model is defined via the

ISOTROPIC HARDENING FUNCTIONcommand line.The optional rate multiplier for the flow stress hardening model is defined with the

RATE MULTIPLIERcommand line.The optional temperature multiplier for the flow stress hardening model is defined via the

TEMPERATURE MULTIPLIERcommand line.The function name of a user-defined temperature multiplier is defined with the

TEMPERATURE MULTIPLIER FUNCTIONcommand line.For a Johnson-Cook temperature multiplier, the melting temperature, \(\theta_{\text{melt}}\), is defined via the

MELTING TEMPERATUREcommand line.For a Johnson-Cook temperature multiplier, the reference temperature, \(\theta_{\text{ref}}\), is defined via the

REFERENCE TEMPERATUREcommand line.For a Johnson-Cook temperature multiplier, the temperature exponent, \(M\), is defined via the

TEMPERATURE EXPONENTcommand line.The optional rate multiplier for the yield stress for the decoupled flow stress hardening model is defined with the

YIELD RATE MULTIPLIERcommand line.The optional rate multiplier for the hardening for the decoupled flow stress hardening model is defined with the

HARDENING RATE MULTIPLIERcommand line.The optional temperature multiplier for the yield stress for the decoupled flow stress hardening model is defined with the

YIELD TEMPERATURE MULTIPLIERcommand line.The optional temperature multiplier for the hardening for the decoupled flow stress hardening model is defined via the

HARDENING TEMPERATURE MULTIPLIERcommand line.

Output variables available for this model are listed in Table 5.11.

Name |

Description |

|---|---|

|

equivalent plastic strain, \(\bar{\varepsilon}^{p}\) |

|

equivalent plastic strain rate, \(\dot{\bar{\varepsilon}}^{p}\) |

|

effective stress, \(\phi\) |

|

tensile equivalent plastic strain, \(\bar{\varepsilon}^{p}_{t}\) |

|

damage, \(\phi\) |

|

void count, \(\eta\) |

|

void size, \(\upsilon\) |

|

damage rate, \(\dot{\phi}\) |

|

void count rate, \(\dot{\eta}\) |

|

plastic work heat rate, \(\dot{Q}^p\) |

5.2.14. Hosford Plasticity Model

BEGIN PARAMETERS FOR MODEL HOSFORD_PLASTICITY

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Yield surface parameters

#

YIELD STRESS = <real>

A = <real> (1.0)

#

# Hardening model

#

HARDENING MODEL = LINEAR | POWER_LAW | VOCE | USER_DEFINED |

FLOW_STRESS | DECOUPLED_FLOW_STRESS | JOHNSON_COOK |

POWER_LAW_BREAKDOWN

#

# Linear hardening

#

HARDENING MODULUS = <real>

#

# Power-law hardening

#

HARDENING CONSTANT = <real>

HARDENING EXPONENT = <real> (0.5)

LUDERS STRAIN = <real> (0.0)

#

# Voce hardening

#

HARDENING MODULUS = <real>

EXPONENTIAL COEFFICIENT = <real>

#

# Johnson-Cook hardening

#

HARDENING FUNCTION = <string>hardening_function_name

RATE CONSTANT = <real>

REFERENCE RATE = <real>

#

# Power law breakdown hardening

#

HARDENING FUNCTION = <string>hardening_function_name

RATE COEFFICIENT = <real>

RATE EXPONENT = <real>

# User defined hardening

#

HARDENING FUNCTION = <string>hardening_function_name

#

#

# Following Commands Pertain to Flow_Stress Hardening Model

#

# - Isotropic Hardening model

#

ISOTROPIC HARDENING MODEL = LINEAR | POWER_LAW | VOCE |

USER_DEFINED

#

# Specifications for Linear, Power-law, and Voce same as above

#

# User defined hardening

#

ISOTROPIC HARDENING FUNCTION = <string>iso_hardening_fun_name

#

# - Rate dependence

#

RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Specifications for Johnson-Cook, Power-law-breakdown

# same as before EXCEPT no need to specify a

# hardening function

#

# User defined rate multiplier

#

RATE MULTIPLIER FUNCTION = <string> rate_mult_function_name

#

# - Temperature dependence

#

TEMPERATURE MULTIPLIER = JOHNSON_COOK | USER_DEFINED |

TEMPERATURE_INDEPENDENT (TEMPERATURE_INDEPENDENT)

#

# Johnson-Cook temperature dependence

#

MELTING TEMPERATURE = <real>

REFERENCE TEMPERATURE = <real>

TEMPERATURE EXPONENT = <real>

#

# User-defined temperature dependence

TEMPERATURE MULTIPLIER FUNCTION = <string>temp_mult_function_name

#

# Following Commands Pertain to Decoupled_Flow_Stress Hardening Model

#

# - Isotropic Hardening model

#

ISOTROPIC HARDENING MODEL = LINEAR | POWER_LAW | VOCE | USER_DEFINED

#

# Specifications for Linear, Power-law, and Voce same as above

#

# User defined hardening

#

ISOTROPIC HARDENING FUNCTION = <string>isotropic_hardening_function_name

#

# - Rate dependence

#

YIELD RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Specifications for Johnson-Cook, Power-law-breakdown same as before

# EXCEPT no need to specify a hardening function

# AND should be preceded by YIELD

#

# As an example for Johnson-Cook yield rate dependence,

#

YIELD RATE CONSTANT = <real>

YIELD REFERENCE RATE = <real>

#

# User defined rate multiplier

#

YIELD RATE MULTIPLIER FUNCTION = <string>yield_rate_mult_function_name

#

HARDENING_RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Syntax same as for yield parameters but with a HARDENING prefix

#

# - Temperature dependence

#

YIELD TEMPERATURE MULTIPLIER = JOHNSON_COOK | USER_DEFINED |

TEMPERATURE_INDEPENDENT (TEMPERATURE_INDEPENDENT)

#

# Johnson-Cook temperature dependence

#

YIELD MELTING TEMPERATURE = <real>

YIELD REFERENCE TEMPERATURE = <real>

YIELD TEMPERATURE EXPONENT = <real>

#

# User-defined temperature dependence

YIELD TEMPERATURE MULTIPLIER FUNCTION = <string>yield_temp_mult_fun_name

#

HARDENING TEMPERATURE MULTIPLIER = JOHNSON_COOK | USER_DEFINED |

TEMPERATURE_INDEPENDENT (TEMPERATURE_INDEPENDENT)

#

# Syntax for hardening constants same as for yield but

# with HARDENING prefix

#

# Optional Failure Definitions

# Following only need to be defined if intend to use failure model

#

FAILURE MODEL = TEARING_PARAMETER | JOHNSON_COOK_FAILURE | WILKINS

| MODULAR_FAILURE | MODULAR_BCJ_FAILURE

CRITICAL FAILURE PARAMETER = <real>

#

# TEARING_PARAMETER Failure model definitions

#

TEARING PARAMETER EXPONENT = <real>

#

# JOHNSON_COOK_FAILURE Failure model definitions

#

JOHNSON COOK D1 = <real>

JOHNSON COOK D2 = <real>

JOHNSON COOK D3 = <real>

JOHNSON COOK D4 = <real>

JOHNSON COOK D5 = <real>

#

#Following Johnson-Cook parameters can only be defined once. As such, only

# needed if not previously defined via Johnson-Cook multipliers

# w/ flow-stress hardening. Does need to be defined

# w/ Decoupled Flow Stress

#

REFERENCE RATE = <real>

REFERENCE TEMPERATURE = <real>

MELTING TEMPERATURE = <real>

#

# WILKINS Failure model definitions

#

WILKINS ALPHA = <real>

WILKINS BETA = <real>

WILKINS PRESSURE = <real>

#

# MODULAR_FAILURE Failure model definitions

#

PRESSURE MULTIPLIER = PRESSURE_INDEPENDENT | WILKINS

| USER_DEFINED (PRESSURE_INDEPENDENT)

LODE ANGLE MULTIPLIER = LODE_ANGLE_INDEPENDENT |

WILKINS (LODE_ANGLE_INDEPENDENT)

TRIAXIALITY MULTIPLIER = TRIAXIALITY_INDEPENDENT | JOHNSON_COOK

| USER_DEFINED (TRIAXIALITY_INDEPENDENT)

RATE FAIL MULTIPLIER = RATE_INDEPENDENT | JOHNSON_COOK

| USER_DEFINED (RATE_INDEPENDENT)

TEMPERATURE FAIL MULTIPLIER = TEMPERATURE_INDEPENDENT | JOHNSON_COOK

| USER_DEFINED (TEMPERATURE_INDEPENDENT)

#

# Individual multiplier definitions

#

PRESSURE MULTIPLIER = WILKINS

WILKINS ALPHA = <real>

WILKINS PRESSURE = <real>

#

PRESSURE MULTIPLIER = USER_DEFINED

PRESSURE MULTIPLIER FUNCTION = <string> pressure_multiplier_fun_name

#

LODE ANGLE MULTIPLIER = WILKINS

WILKINS BETA = <real>

#

TRIAXIALITY MULTIPLIER = JOHNSON_COOK

JOHNSON COOK D1 = <real>

JOHNSON COOK D2 = <real>

JOHNSON COOK D3 = <real>

#

TRIAXIALITY MULTIPLIER = USER_DEFINED

TRIAXIALITY MULTIPLIER FUNCTION = <string> triaxiality_multiplier_fun_name

#

RATE FAIL MULTIPLIER = JOHNSON_COOK

JOHNSON COOK D4 = <real>

# REFERENCE RATE should only be added if not previously defined

REFERENCE RATE = <real>

#

RATE FAIL MULTIPLIER = USER_DEFINED

RATE FAIL MULTIPLIER FUNCTION = <string> rate_fail_multiplier_fun_name

#

TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK

JOHNSON COOK D5 = <real>

# JC Temperatures should only be defined if not previously given

REFERENCE TEMPERATURE = <real>

MELTING TEMPERATURE = <real>

#

TEMPERATURE FAIL MULTIPLIER = USER_DEFINED

TEMPERATURE FAIL MULTIPLIER FUNCTION = <string> temp_multiplier_fun_name

#

# MODULAR BCJ_FAILURE Failure model definitions

#

INITIAL DAMAGE = <real>

INITIAL VOID SIZE = <real>

DAMAGE BETA = <real> (0.5)

GROWTH MODEL = COCKS_ASHBY | NO_GROWTH (NO_GROWTH)

NUCLEATION MODEL = HORSTEMEYER_GOKHALE | CHU_NEEDLEMAN_STRAIN

| NO_NUCLEATION (NO_NUCLEATION)

#

GROWTH RATE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| RATE_INDEPENDENT

(RATE_INDEPENDENT)

GROWTH TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| TEMPERATURE_INDEPENDENT

(TEMPERATURE_INDEPENDENT)

#

NUCLEATION RATE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| RATE_INDEPENDENT

(RATE_INDEPENDENT)

NUCLEATION TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK | USER_DEFINED

| TEMPERATURE_INDEPENDENT

(TEMPERATURE_INDEPENDENT)

#

# Definitions for individual growth and nucleation models

#

GROWTH MODEL = COCKS_ASHBY

DAMAGE EXPONENT = <real> (0.5)

#

NUCLEATION MODEL = HORSTEMEYER_GOKHALE

NUCLEATION PARAMETER1 = <real> (0.0)

NUCLEATION PARAMETER2 = <real> (0.0)

NUCLEATION PARAMETER3 = <real> (0.0)

#

NUCLEATION MODEL = CHU_NEEDLEMAN_STRAIN

NUCLEATION AMPLITUDE = <real>

MEAN NUCLEATION STRAIN = <real>

NUCLEATION STRAIN STD DEV = <real>

#

# Definitions for rate and temperature fail multiplier

# Note: only showing definitions for growth.

# Nucleation terms are the same just with NUCLEATION instead

# of GROWTH

#

GROWTH RATE FAIL MULTIPLIER = JOHNSON_COOK

GROWTH JOHNSON COOK D4 = <real>

GROWTH REFERENCE RATE = <real>

#

GROWTH RATE FAIL MULTIPLIER = USER_DEFINED

GROWTH RATE FAIL MULTIPLIER FUNCTION = <string> growth_rate_fail_mult_func

#

GROWTH TEMPERATURE FAIL MULTIPLIER = JOHNSON_COOK

GROWTH JOHNSON COOK D5 = <real>

GROWTH REFERENCE TEMPERATURE = <real>

GROWTH MELTING TEMPERATURE = <real>

#

GROWTH TEMPERATURE FAIL MULTIPLIER = USER_DEFINED

GROWTH TEMPERATURE FAIL MULTIPLIER FUNCTION = <string> temp_fail_mult_func

#

#

# Optional Adiabatic Heating/Thermal Softening Definitions

# Following only need to be defined if intend to use failure model

#

THERMAL SOFTENING MODEL = ADIABATIC | COUPLED

#

SPECIFIC HEAT = <real> #not needed for COUPLED

BETA_TQ = <real>

END [PARAMETERS FOR MODEL HOSFORD_PLASTICITY]

Like other elastic-plastic models in LAMÉ, the Hosford plasticity model is a rate-independent hypoelastic formulation. Unlike the Hill and other more complex plasticity models, it is isotropic. In a similar fashion to those models, the total rate of deformation is additively decomposed into an elastic and plastic part such that

The objective stress rate, depending only on the elastic deformation, may then be written as,

The Hosford plasticity model utilizes a yield surface first put forth by W. F. Hosford in the 1970’s [[13]] that is isotropic but non-quadratic. This specific form was proposed due to experimental observations of biaxial stretching in which neither the Tresca or \(J_2\) yield surfaces could describe the results. In contrast to many of the yield surfaces proposed for similar purposes, only two parameters are utilized. Even with these limited terms, the developed model is quite versatile and can be reduced to von Mises or Tresca conditions as well as capturing responses in between. This yield surface is given as,

in which \(\phi\left(\sigma_{ij}\right)\) is the Hosford effective stress and \(\bar{\sigma}\left(\bar{\varepsilon}^p\right)\) is the current yield stress that may depend on rate and/or temperature. The Hosford effective stress is a non-quadratic function of the principal stresses (\(\sigma_i, i=1,2,3\)) and is given as

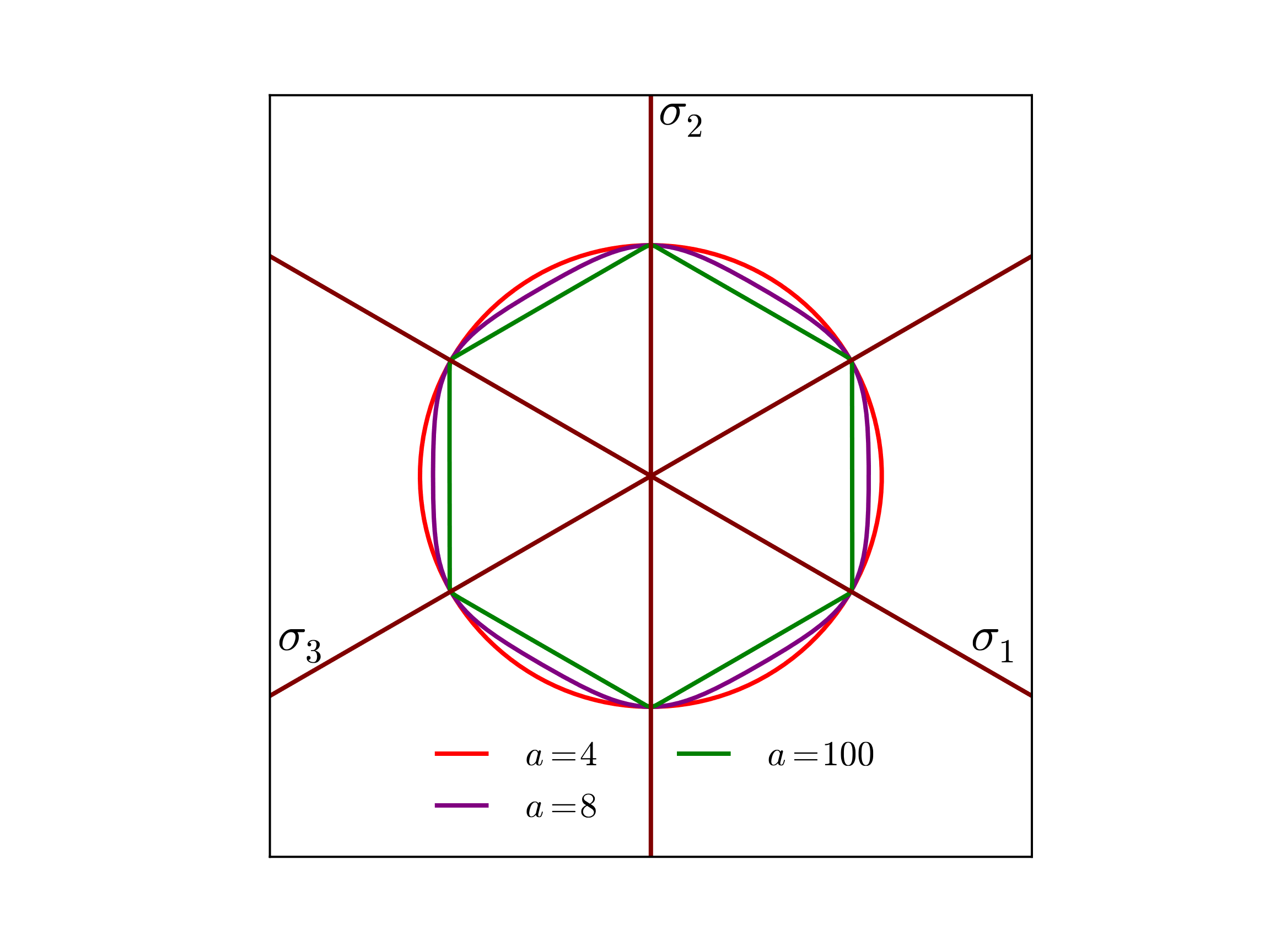

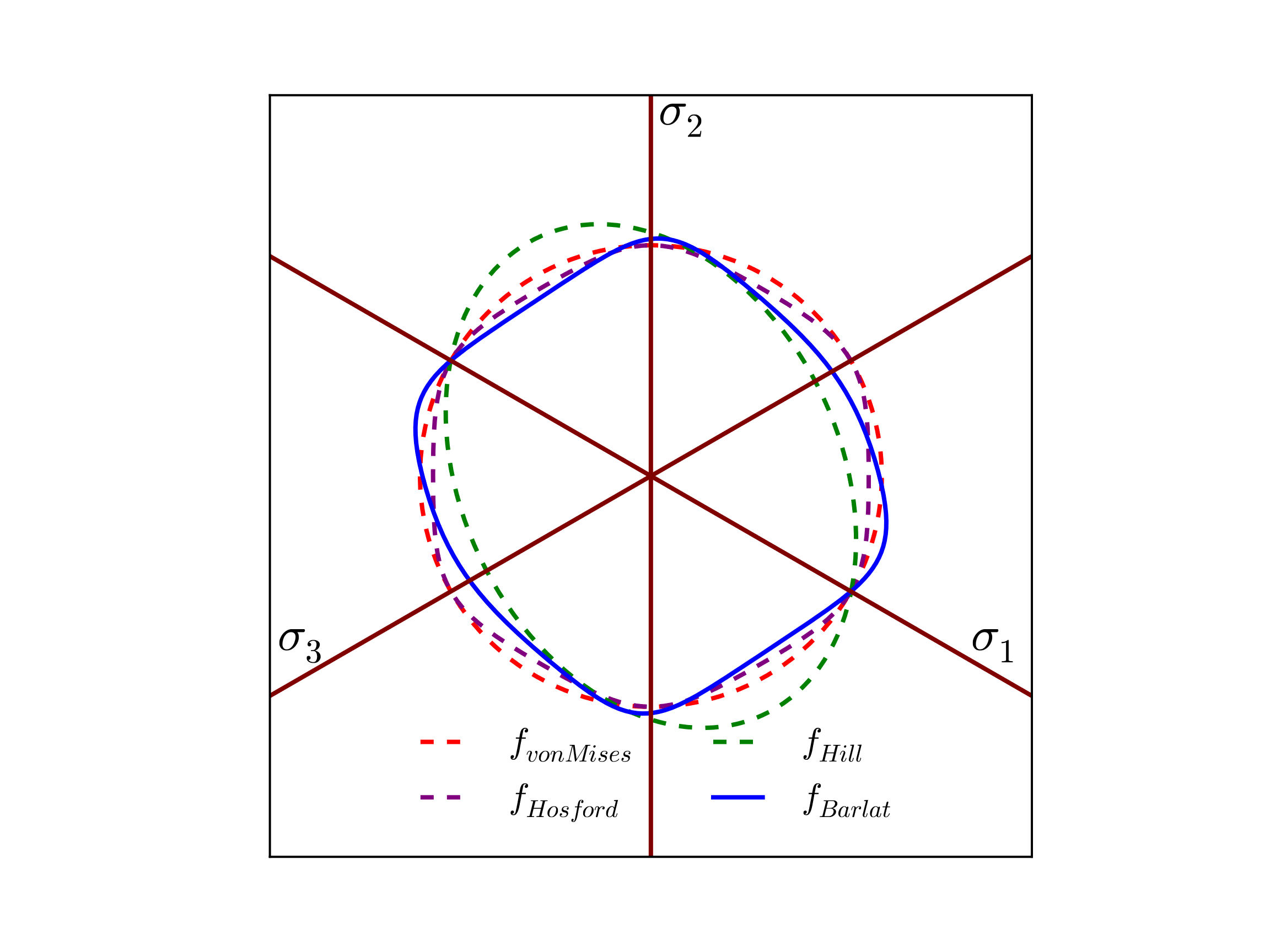

in which \(a\) is the yield surface exponent. Interestingly, if \(a=2\) or \(4\) the yield surface reduces to that of a \(J_2\) von Mises surface while \(a=1\) or as \(a\rightarrow\infty\) produces a Tresca like shape. If the value of \(a\) is above 4 the yield surface takes a position between the Tresca and \(J_2\) limits. Typical values are \(a=6\) or \(a=8\) for bcc and fcc metals, respectively [[14]]. To highlight this variability the yield surface is plotted below in Fig. 5.7 for three values of \(a\) – \(a = 4, 8,\) and 100.

Fig. 5.7 Example Hosford yield surfaces, \(f\left(\sigma_{ij},\bar{\varepsilon}^p=0;a\right)\), presented in the deviatoric \(\pi\)-plane. The presented surfaces correspond to the different yield exponents \(a = 4, 8,\) and \(100\).

For the hardening function, \(\bar{\sigma}\left(\bar{\varepsilon}^p\right)\), a variety of forms including linear, power law, or a more general user defined function may be used.

An associated flow rule is utilized such that the plastic rate of deformation is normal to the yield surface and is given by,

where \(\dot{\gamma}\) is the consistency multiplier enforcing \(f=0\) during plastic deformation. Given the form of \(f\), it can also be shown that \(\dot{\gamma}=\dot{\bar{\varepsilon}}^p\).

For details on the plasticity model, please see [[15]]. Additional details on failure models and adiabatic heating capabilities may be found in [[10], [11]] and [[12]], respectively.

In the command blocks that define the Hosford plasticity model:

See Section 5.1.5 for more information on elastic constants input.

The reference nominal yield stress, \(\bar{\sigma}\), is defined with the

YIELD STRESScommand line.The yield surface exponent, \(a\), is defined with the

Acommand line.The type of hardening law is defined with the

HARDENING MODELcommand line, other hardening commands then define the specific shape of that hardening curve.The hardening modulus for a linear hardening model is defined with the

HARDENING MODULUScommand line.The hardening constant for a power law hardening model is defined with the

HARDENING CONSTANTcommand line.The hardening exponent for a power law hardening model is defined with the

HARDENING EXPONENTcommand line.The L"{u}ders strain for a power law hardening model is defined with the

LUDERS STRAINcommand line.The hardening function for a user defined hardening model is defined with the

HARDENING FUNCTIONcommand line.The shape of the spline for the spline based hardening is defined by the

CUBIC SPLINE TYPE,CARDINAL PARAMETER,KNOT EQPS, andKNOT STRESScommand lines.

Output variables available for this model are listed in Table 5.12.

Name |

Description |

|---|---|

|

equivalent plastic strain, \(\bar{\varepsilon}^{p}\) |

|

equivalent plastic strain rate, \(\dot{\bar{\varepsilon}}^{p}\) |

|

effective stress, \(\phi\) |

|

tensile equivalent plastic strain, \(\bar{\varepsilon}^{p}_{t}\) |

|

damage, \(\phi\) |

|

void count, \(\eta\) |

|

void size, \(\upsilon\) |

|

damage rate, \(\dot{\phi}\) |

|

void count rate, \(\dot{\eta}\) |

|

plastic work heat rate, \(\dot{Q}^p\) |

5.2.15. Hill Plasticity Model

BEGIN PARAMETERS FOR MODEL HILL_PLASTICITY

#

# Elastic constants

#

YOUNGS MODULUS = <real>

POISSONS RATIO = <real>

SHEAR MODULUS = <real>

BULK MODULUS = <real>

LAMBDA = <real>

TWO MU = <real>

#

# Material coordinates system definition

#

COORDINATE SYSTEM = <string> coordinate_system_name

DIRECTION FOR ROTATION = <real> 1|2|3

ALPHA = <real> (degrees)

SECOND DIRECTION FOR ROTATION = <real> 1|2|3

SECOND ALPHA = <real> (degrees)

#

# Yield surface parameters

#

YIELD STRESS = <real>

R11 = <real> (1.0)

R22 = <real> (1.0)

R33 = <real> (1.0)

R12 = <real> (1.0)

R23 = <real> (1.0)

R31 = <real> (1.0)

#

# Hardening model

#

HARDENING MODEL = LINEAR | POWER_LAW | VOCE | USER_DEFINED |

FLOW_STRESS | DECOUPLED_FLOW_STRESS | JOHNSON_COOK |

POWER_LAW_BREAKDOWN

#

# Linear hardening

#

HARDENING MODULUS = <real>

#

# Power-law hardening

#

HARDENING CONSTANT = <real>

HARDENING EXPONENT = <real> (0.5)

LUDERS STRAIN = <real> (0.0)

#

# Voce hardening

#

HARDENING MODULUS = <real>

EXPONENTIAL COEFFICIENT = <real>

#

# Johnson-Cook hardening

#

HARDENING FUNCTION = <string>hardening_function_name

RATE CONSTANT = <real>

REFERENCE RATE = <real>

#

# Power law breakdown hardening

#

HARDENING FUNCTION = <string>hardening_function_name

RATE COEFFICIENT = <real>

RATE EXPONENT = <real>

# User defined hardening

#

HARDENING FUNCTION = <string>hardening_function_name

#

#

# Following Commands Pertain to Flow_Stress Hardening Model

#

# - Isotropic Hardening model

#

ISOTROPIC HARDENING MODEL = LINEAR | POWER_LAW | VOCE |

USER_DEFINED

#

# Specifications for Linear, Power-law, and Voce same as above

#

# User defined hardening

#

ISOTROPIC HARDENING FUNCTION = <string>iso_hardening_fun_name

#

# - Rate dependence

#

RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Specifications for Johnson-Cook, Power-law-breakdown

# same as before EXCEPT no need to specify a

# hardening function

#

# User defined rate multiplier

#

RATE MULTIPLIER FUNCTION = <string> rate_mult_function_name

#

# - Temperature dependence

#

TEMPERATURE MULTIPLIER = JOHNSON_COOK | USER_DEFINED |

TEMPERATURE_INDEPENDENT (TEMPERATURE_INDEPENDENT)

#

# Johnson-Cook temperature dependence

#

MELTING TEMPERATURE = <real>

REFERENCE TEMPERATURE = <real>

TEMPERATURE EXPONENT = <real>

#

# User-defined temperature dependence

TEMPERATURE MULTIPLIER FUNCTION = <string>temp_mult_function_name

#

# Following Commands Pertain to Decoupled_Flow_Stress Hardening Model

#

# - Isotropic Hardening model

#

ISOTROPIC HARDENING MODEL = LINEAR | POWER_LAW | VOCE | USER_DEFINED

#

# Specifications for Linear, Power-law, and Voce same as above

#

# User defined hardening

#

ISOTROPIC HARDENING FUNCTION = <string>isotropic_hardening_function_name

#

# - Rate dependence

#

YIELD RATE MULTIPLIER = JOHNSON_COOK | POWER_LAW_BREAKDOWN |

USER_DEFINED | RATE_INDEPENDENT (RATE_INDEPENDENT)

#

# Specifications for Johnson-Cook, Power-law-breakdown same as before

# EXCEPT no need to specify a hardening function

# AND should be preceded by YIELD

#

# As an example for Johnson-Cook yield rate dependence,

#

YIELD RATE CONSTANT = <real>